EVER-POWER GROUP CO., LTD. IS SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, PARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAULIC SYSTEM, VACCUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND pto shaft, agricultural gearboxes SO ON.

Overview

Quick Details

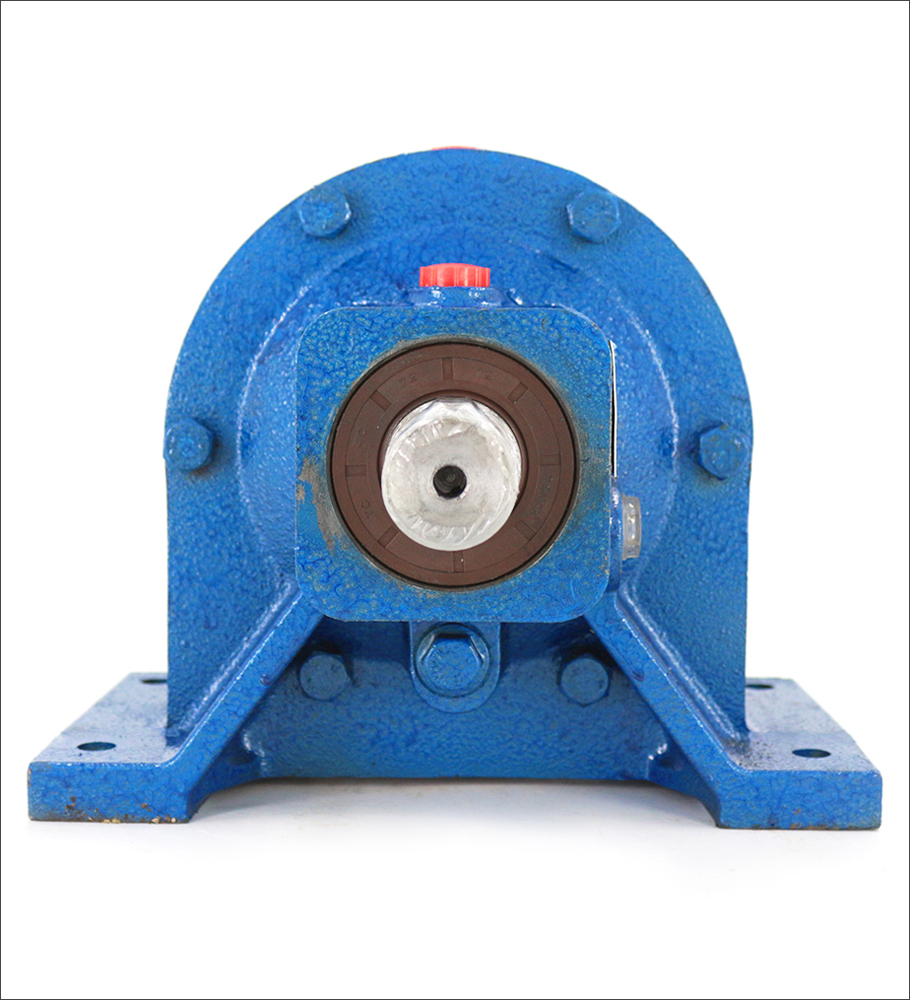

-

Applicable Industries:

-

Our company is located in XiHu HangZhou Zhejiang Province. T

Manufacturing Plant

-

ITEM NO:

-

SYF

-

Color:

-

Blue

-

Product name:

-

BLD Cycloid Speed Reducer

-

Application:

-

Machine Tool

-

Material:

-

Steel

-

Bearing:

-

NSK

-

Certificate:

-

ISO9001

-

Ratio:

-

9-28800

-

Mounting Position:

-

Horizontal (foot Mounted)

-

Input Form:

-

IEC Flange

Packaging & Delivery

-

Lead Time

:

-

| Quantity(Bags) |

1 – 1000 |

>1000 |

| Est. Time(days) |

10 |

To be negotiated |

Online Customization

Product Description

Cycloidal gear reducer is a principle adopted K-H-V Planetary Gear less innovative gear. Its transmission process as follows : input shaft equipped with a 180-degree dislocation of the double eccentric sets, replaced with two eccentric turn as a roller bearing arm, the formation of H-, two cycloid round hole at the center shall uplink Eccentric Roller Bearings arm, which cycloidal gear needle round and meshing phase, comprising a difference of the teeth meshing with the gearbox.

|

Type

|

stage

|

Model

|

Ratio

|

Nominal Power (KW)

|

Nominal Torque(N.m)

|

|

X/B Series Cycloidal Reducer

|

Single reducer

|

B09/X1

|

9-87

|

0.55-0.18

|

26-50

|

|

|

|

B0/X2

|

|

1.1-0.18

|

58-112

|

|

|

|

B1/X3

|

|

0.55-0.18

|

117-230

|

|

|

|

B2/X4

|

|

4-0.55

|

210-400

|

|

|

|

B3/X5

|

|

11-0.55

|

580-1010

|

|

|

|

B4/X6/X7

|

|

11-2.2

|

580-1670

|

|

|

|

B5/X8

|

|

18.5-2.2

|

1191-3075

|

|

|

|

B6/X9

|

|

15-5.5

|

5183-5605

|

|

|

|

B7/X10

|

|

11-45

|

7643

|

|

Type

|

stage

|

Model

|

Ratio

|

Nominal Power (KW)

|

Nominal Torque(N.m)

|

|

X/B Series Cycloidal reducer

|

Double reducer

|

B10/X32

|

99-7569

|

0.37-0.18

|

175

|

|

|

|

B20/X42

|

|

1.1-0.18

|

600

|

|

|

|

B31/X53

|

|

2.2-0.25

|

1250

|

|

|

|

B41/X63

|

|

2.2-0.25

|

1179-2500

|

|

|

|

B42/X64

|

|

4-0.55

|

2143-2500

|

|

|

|

B52/X84

|

|

4-0.55

|

2143-5000

|

|

|

|

B53/X85

|

|

7.5-0.55

|

5000

|

|

|

|

B63/X95

|

|

7.5-0.55

|

5893-8820

|

|

|

|

B74/X106

|

|

11-2.2

|

11132-12000

|

|

|

|

B84/X117

|

|

11-2.2

|

11132-16000

|

Main Features

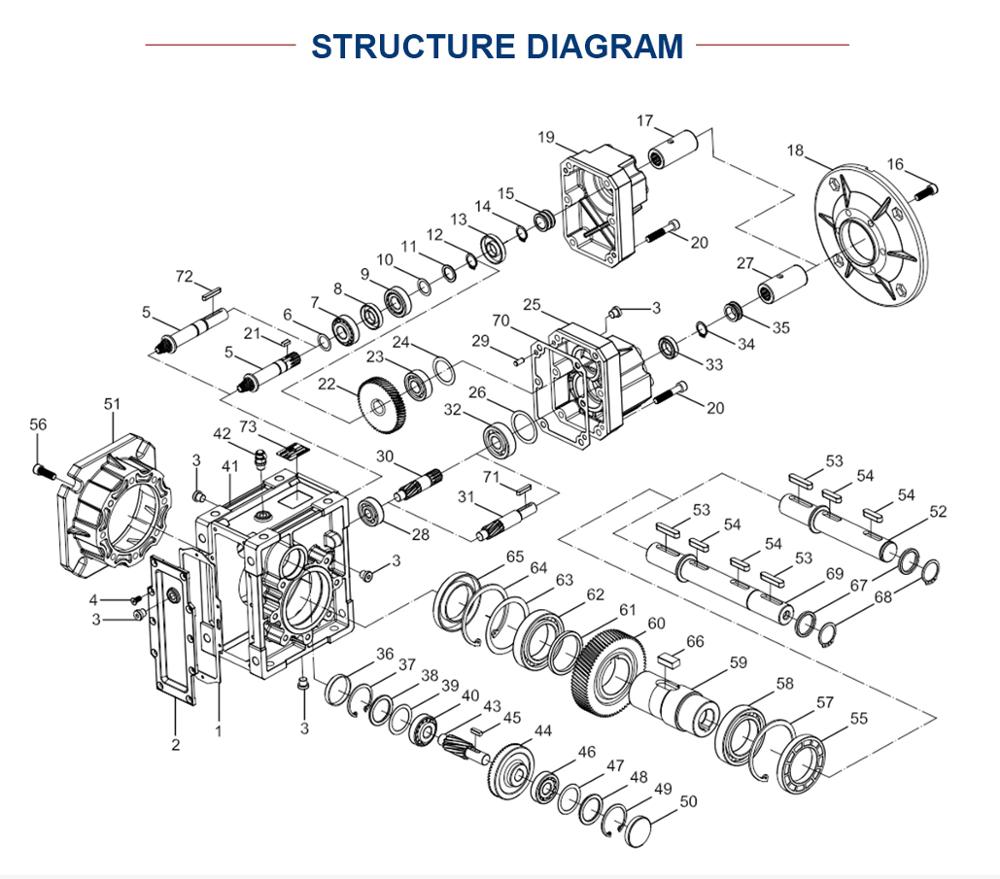

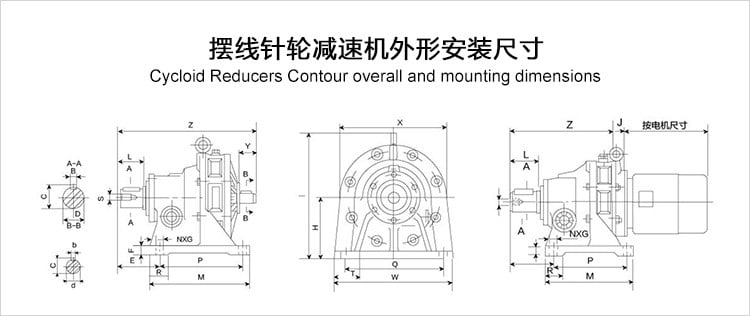

All planetary cycloidal reducer rotating device can be divided into three parts:input part,deceleration part and output part.

Dislocation on the input shaft is equipped with a 180℃ of double eccentric sleeve,equipped with two ball bearings on the eccentric sleeve,the formation of H two cycloid gear center hole is the eccentric sleeve on the turning arm bearing raceway,and by a groud of cycloid gear and pin gear ring of gear meshing,less bad tooth meshing reduction mechanism to form,(in order to reduce friction,in small ratio of speed reducer,the needle with needle teeth on the gear set).

When the input shaft with eccentric sleeve rotation for a week,as a result of the cycloid gear tooth profile curve characteristics and restricted by needle on the gear teeth,the movement of the cycloid gear becoming both revolution and rotation of the plane movement,and input shaft are

made for a week,eccentric sleeve also turn the week,cycloid gear in the opposite direction around a big tooth difference reduction is obtained, then with the help pf W output mechanism,the cycloid gear rotates at low speed movement through the pin shaft,passed to the output shaft,low output speed can be achieved.

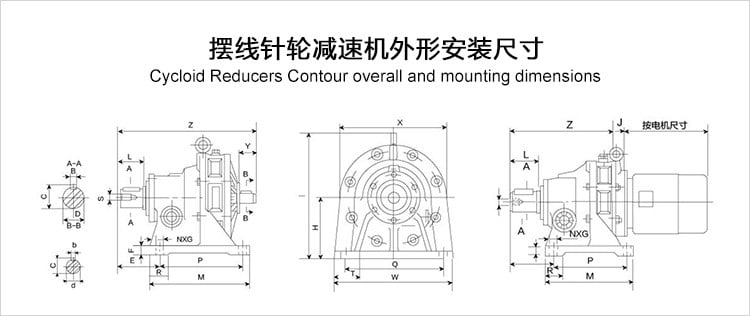

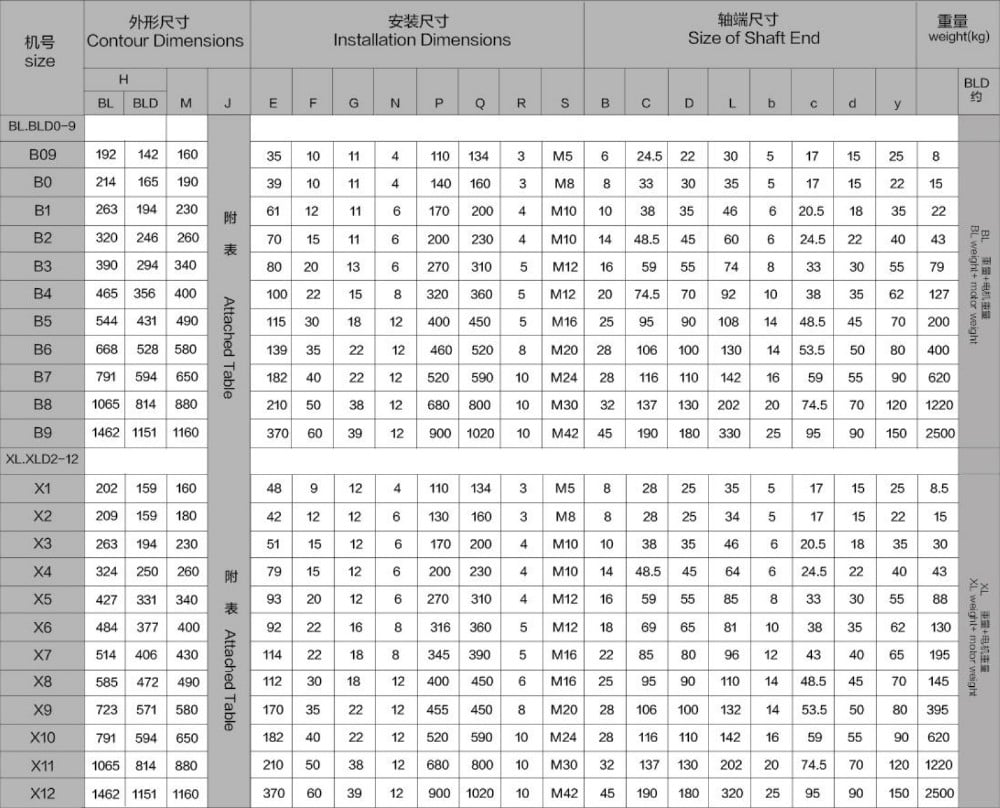

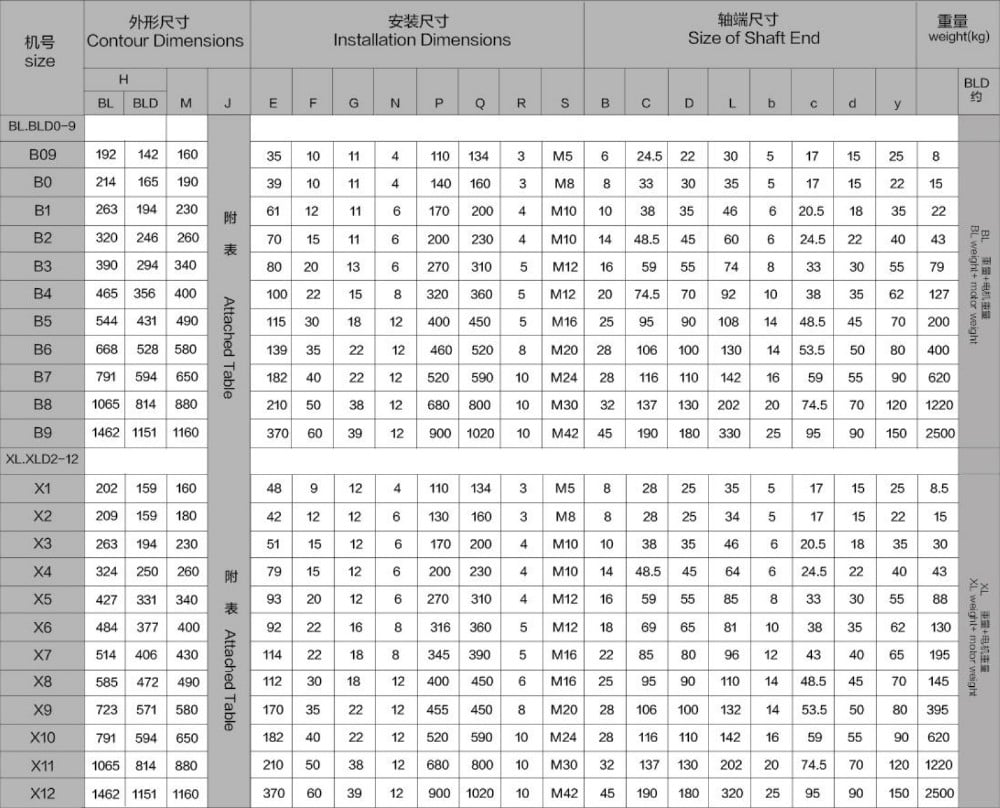

The Designation of Cycloidal Reducers

Example: BL(E)D41-1225-0.37-WB: B series cyclo drive gearboxL: Vertical mounted with flange, Shaft downward(E): None-one stage, E-two stage, S-three stageD:Standard electric motors41: Model number 411225: Speed Reduction Ratio

0.37: Electric motor power:0.37kwW: Mounting way.

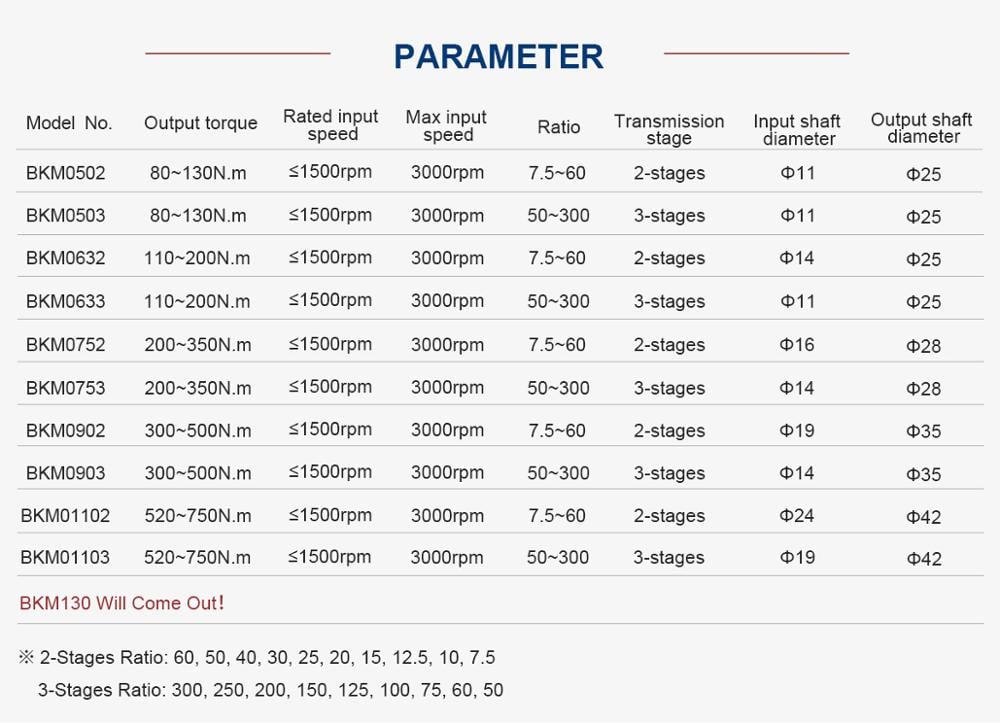

Basic Parameters

Power range: 0.25 – 90kW

Output speed(r/min): 0.011 – 161Output Torque(N.M): Top to 22920N.m

All models of this cycloidal motor reducer are

BW0、、BWD0、BW1、BWD1、BW2、BWD2、BW3、BWD3、BW4、BWD4、BW5、BWD5、BW6、BWD6、BW7、BWD7、BW8、BWD8、BW9、BWD9、BL0、BLD0、BL1、BLD1、BL2、BLD2、BL3、BLD3、BL4、BLD4、BL5、BLD5、BL6、BLD6、BL7、BLD7、BL8、BLD8、BL9、BLD9、

BWE20、BWED20、BWE30、BWED30、BWE31、BWED31、BWE41、BWED41、BWE42、BWED42、BWE52、BWED52、BWE53、BWED53、BWE63、BWED63、BWE74、BWED74、BWE85、BWED85、BWE95

BW12、BWD12、BW15、BWD15、BW18、BWD18、BW22、BWD22、BW27、BWD27、BW33、BWD33、BW39、WD39、BW45、BWD45、BW55、BWD55、

BL12、BLD12、BL15、BLD15、BL18、BLD18、BL22、BLD22、BL27、BLD27、BL33、BLD33、BL39、LD39、BL45、BLD45、BL55、BLD55、

BWE1512、BWED1512、BWE1812、BWED1812、BWE2212、BWED2212、BWE2215、BWED2215、BWE2715、BWED2715、BWE2718、BWED2718、BWE3318、BWED3318

XW0、XW1、XW2、XW3、XW4、XW5、XW6、XW7、XW8、XW9、XW10、XW11、XW12

XWD1、XWD2、XWD3、XWD4、XWD5、XWD6、XWD7、XWD8、XWD9、XWD10、XWD11、XWD12

XL0、XL1、XL2、XL3、XL4、XL5、XL6、XL7、XL8、XL9、XL10、XL11、XL1

XLD1、XLD2、XLD3、XLD4、XLD5、XLD6、XLD7、XLD8、XLD9、XLD10、XLD11、XLD12

XWED20、XWED32、XWED42、XWED53、XWED63、XWED74、XWED84、XWED85、XWED95、XWED106、XWED128

XLE20、XLE32、XLE42、XLE53、XLE63、XLE74、XLE84、XLE85、XLE95、XLE106、XLE128

XLED20、XLED32、XLED42、XLED53、XLED63、XLED74、XLEDK84、XLED85、XLED95、XLED106、XLED128

XJ0、JXJ0、XJ1、JXJ1、XJ2、JXJ2、XJ3、JXJ3、XJ4、JXJ4、XJ5、JXJ5、XJ6、JXJ6、

XJL0、JXJL0、XJL1、JXJL1、XJL2、JXJL2、XJL3、JXJL3、XJL4、JXJL4、XJL5、JXJL5、XJL6、JXJL6、XJE10、JXJE10、XJE20、JXJE20、XJE31、JXJE31、XJE41、JXJE41、XJE42、JXJE42、XJE52、JXJE52、XJE53、JXJE53、XJE63、JXJE63、

XJLE10、JXJLE10、XJLE20、JXJLE20、XJLE31、JXJLE31、XJLE41、JXJLE41、XJLE42

Reduction ratio mainly is 7,9,11,17,23,29,35,43,59,71,87,99,121,187,289,391,493,595,731,841,1003,1225,1505,1849,2065,2537,3481,4189,5133,7569.

Paint Color: Various

Material: Rugged cast iron or ductile housings

Lubrication: Grease or oil lubricated models available.

Seals: Nitrile material, dual lipped, double output seals available.

Working: 24 hours continuous available and shaft forward reverse

Reducer Reduction: Internal planetary gear mechanism with trochoidal curved tooth profile.

Atmosphere: Well ventilated location, free of corrosive gases, explosive gases, vapors and dust

Application :

• Conveyors • Sawmills and Wood Mills • Food Machinery • Wastewater Treatment• Mixers • Steel Mills • Automotive Plants • Construction Equipment• Paper Mills • Recycling Machines • Poultry Plants • Processing Plants• Oil Press Machine • Rotary Feeder

What are our unique advantages in making Cycloidal Reducers your choice factory infrastructure investment?

we can help you:

● Providing proper type gearbox and combined gearbox to meet your application needs;

● Better managing maintenance cost and lifting operation efficiency;

● Improving production capacity and boosting economic profitability.

cycloidal gear reducer is widely used in many industries such as Textile manufacturing and food industry. it is small but very good quality. This kind of gear reducer can divided into three parts, the input , the reduction part and the output shaft. There is a double eccentric locking collars in the input part. when input shaft turns a round, the eccentric locking collars will also turns a round so that transfer to the reduction part. to make the output shaft turns. so it make torques. Efficiency can get to 95% . Usually, there are two mounting way and this is vertical mounting.It can be widely used in industry of Coal, steel, machinery, chemical, textile, mixer etc. This can have one stage, two stages and three stages reduction gear. If you want it with flange, we can make. the price with flange or without flange is same.

How to choose a proper type of Gearbox : It is recommended that as much as possible of the following information be given in the enquiry or order so that a check can be made and advice given on the most suitable size of Worm Speed Reducer for any application.1.Type of prime mover.2. Horse-power of prime mover.3. Output torque required from driven member. 4. Input speed of gear unit.5. Output speed of gear unit. 6. Configuration of drive required and shaft disposition. 7. Total daily hours of running. If running is intermitteTo get the type-choose reference,please contact our technical rep or sales rep .

Characteristics:

1.Cycloid reducer big reduction ratio, high efficiency: a reduction gear ratio is 9~87, the two-stage reduction gear ratio is 121 ~ 5133, multistage combination can reach tens of thousands, and the needle tooth meshing line type rolling friction, the meshing surface no relative sliding, so a reduction efficiency of 94%.

2.Pin wheel reducer smooth running, low noise: the teeth contact at the same time when in operation, the coincidence degree high, stable running, strong overload capacity, low vibration and noise, a variety of models, small noise.

3. The use of reliable, long life: because the main part is made of high carbon alloy steel quenching (HRC58-62), and then grinding, and cycloid gear and pin gear set mesh transfer to the pin gear form rolling friction pair, friction coefficient is small, so that the meshing zone no relative sliding, wear small, so durable.

4. Compact structure, small volume: compared with other reducer with the power of the above weight, small volume 1/3, as is the planetary transmission, the input shaft and the output shaft in the same axis, in order to obtain the smallest possible size.

Cycloidal drive vs. planetary gear To eliminate contact-pattern inconsistencies, EPT developed an automated centering machine that accurately measures each worm and gear subassembly, as well as the reducer housing and bearing covers. A computer records the data and calculates the thickness and location of shims required to exactly center the gear under the worm shaft and, at the same time, provides the appropriate end 1play for the output tapered-roller bearings. This maximizes operating efficiency and minimizes temperature rise. When it comes to large transmission ratios in a compact design, two gear types are particularly suitable: The planetary gear and the cycloidal drive. The similarities between the two gear types become particularly clear when the ring gear of the planetary gearbox is fixed. The gearbox is driven by the sun gear and the output is done by the carrier.Animation: Operating principle of a planetary gear with fixed ring gearIn the case of the planetary gear, the rotary axes are the axes of the planet gears (shown in blue) and in the case of the cycloidal gear, the axes of the cycloidal discs. While the planet gears are driven by a sun gear, the cycloid discs are driven by an eccentric shaft. As they rotate, the planet gears move around the inside of the ring gear. In the same way, the cycloid discs rotate around the fixed pins arranged in a circle. The motion of the planet gears drives the carrier and transmits the power to the output shaft. In the same way, the motion of the cycloidal discs drives a pin disc, which in turn transmits the power to the output shaft. Planetary gear Cycloidal drivemoving axlesplanet gears cycloidal discsdriven by sun gear eccentric shaftorbiting ring gear fixed ring pinsdriving the carrier pin disc

Compared to planetary gears, cycloidal drives are very robust against shock loads. In addition, cycloidal drives achieve significantly better positioning accuracy due to their very low backlash and high torsional stiffness. Therefore cycloidal drives are ideally suited for all types of drive technologies (e.g. for servo motors in robotics) and especially for heavy loads.Cycloidal drives generally have a lower mass and a more compact design than planetary gears, especially at high transmission ratios, and have a longer service life. At relatively low gear ratios of less than 20, however, planetary gears usually offer better advantages and higher efficiency, depending on the application.

Our Company

HangZhouYinxin Electromechanical Facilities Co. Ltd

HangZhouYinxin Electromechanical Equipment Co., Ltd.is a gift enterprise integrating development, design, production and sales,Main promoting products include reducer motor,water pump,construction machinery and parts,bearings,hardware and electrical equipment,plastic products,Labour protection appliance.Our company always follow the operation concept which contains people-oriented, innovation as the soul,be prepared for danger in times of peace, unremitting……

Application area

What do our customers use Cycloidal Drives for?Cycloidal Drive Gear Motor for Travel Motors in Automated Guided VehiclesCycloidal Drive Gear Motor for Production Line Conveyor SystemsCycloidal Drive Gear Motor for Chemical Industry Mixers & AgitatorsCycloidal Drive Gear Motor for Pumping, Cooling & Lubrication SystemsCycloidal Drive Gear Motor for Metalworking MachinesCycloidal Drive Gear Motor for Construction MachineryGear Motor for Water Treatment PlantsGear Motor for Recycling MachineryGear Motor for Steel Industry ProductionCycloidal Drive Gear Motor for Sawmills and Woodworking MachinesCycloidal Drive Gear Motor for Food & Sugar Industry Production LinesCycloidal Drive Gear Motor for Heavy Materials Transportation in Rolling MillsCycloidal Drive Gear Motor for Paper Industry Production Lines

Certifications

Sales territory

Packing & Delivery

|

Packaging

|

|

|

Size

|

500 (L) * 500 (W) * 400 (D)

|

|

Weight

|

1.2 T

|

|

Packaging Details

|

The normal package is wooden box(SizeIn our company we are aware of the importance of the users’ safety. That’s why our PTO’s are produced according to legal regulations and European directives and bear the CE sign. A key factor for safety assurance is the accession in the products’ development phase. By all means, the users’ knowledge about the correct use of a PTO drive shaft is vital. This means, that every users’ duty is to read and follow the safety instructions.: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Packaging

|

|

|

Size

|

500 (L) * 500 (W) * 400 (D)

|

|

Weight

|

1.2 T

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

FAQ

Q1: Are you trading company or manufacturer ?

A: We are a manufacturer in ZJ China.welcome to our factory to have a visit.

Q2: How we select models and specifications?

A:You can email us the series name & code (for example: WJ series worm gearbox) as well as requirement details, such as motor power, output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings, it is better.

Q3: How is your price? Can you offer any discount?

A: We will give the best price we can base on your needs and the quantities.

Q4: How long should I wait for the feedback after I send the enquiry?

A: Within 12 hours.

Q5: What is your product warranty period?

A:We offer one year warranty since the vessel departure date left China.

Q6: What industries are your gearboxes being used?

A:Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.