Product Description

|

Product Name |

High Torque Servo Motor Screw Cross Slider Elastomer Flexible Shaft Couplings |

|

Material |

Aluminum alloy |

|

Surface treatment |

Natural color anode |

|

Customized service |

Support light customization and logo customization |

|

Remarks |

The default engraving brand name and size of the product. If you need not engraving, please contact the customer service for comments |

| Packaging Details | Carton box with anti-static package,carton plus with wooden case. |

| Main Products | Shaft Parts, Timing Belt Pulley, Gears, CNC Machining Parts, Sheet Metal Fabrication |

| Certifications(2) | ISO9001:2015, IPMS |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Farms |

| Supply Ability | 100000 Piece/Pieces per Month |

| Dimension | oem provided |

| Surface finish | anodized |

| Lead Time | 25 days |

| Application | Furniture,cabinet |

| Custom | OEM and ODM services are welcome,we can make cutom LOGO and products according to customer’s requests. |

| Quality control Our | Finished product inspection,Warranty available |

| service | Swiss machining;deburring;lathe/turning;5 axis;micromachining |

| Color |

silver,gold,black,red,bulue,and according to the customer requests. |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the real-world applications of flexible couplings in various industries?

Flexible couplings are widely used in a variety of industries to transmit power and motion between rotating shafts while accommodating misalignments and reducing vibrations. Some of the real-world applications of flexible couplings include:

- Industrial Machinery: Flexible couplings are extensively used in industrial machinery such as pumps, compressors, fans, mixers, and conveyors. They help transmit power from motors to driven equipment, while absorbing misalignments and reducing shock loads and vibrations.

- Automotive: In the automotive industry, flexible couplings are used in various applications, including drive shafts, steering systems, and engine accessories. They help transmit power and motion while allowing for misalignment and reducing torsional vibrations.

- Aerospace: In aircraft and aerospace applications, flexible couplings are used in engine systems, landing gear, and flight control systems. They provide reliable power transmission while accommodating misalignment and reducing vibrations in the demanding aerospace environment.

- Marine: Flexible couplings are used in marine propulsion systems to connect the engine to the propeller shaft. They help transmit power and motion while compensating for shaft misalignment and reducing vibrations in marine vessels.

- Renewable Energy: In wind turbines and solar tracking systems, flexible couplings are used to transfer power and motion between the turbine or solar panel and the generator. They allow for misalignment caused by wind and sun direction changes, ensuring optimal energy conversion.

- Oil and Gas: In the oil and gas industry, flexible couplings are used in pumps, compressors, and drilling equipment. They provide reliable power transmission while accommodating misalignments and reducing vibrations in harsh and demanding oilfield environments.

- Mining and Construction: Flexible couplings are used in heavy-duty mining and construction equipment, including excavators, bulldozers, and loaders. They help transmit power from engines to drive systems while compensating for misalignments and reducing vibrations in rugged and challenging environments.

- Food and Beverage: In food processing and packaging machinery, flexible couplings are used to transmit power and motion while meeting strict hygiene and safety requirements. They help prevent contamination while accommodating shaft misalignments.

- Medical Equipment: Flexible couplings are used in medical devices and equipment, including imaging machines and robotic surgical systems. They help transmit motion and power while reducing vibrations and maintaining precision.

- Textile Industry: In textile manufacturing machines, flexible couplings are used in spinning, weaving, and dyeing processes. They help transmit power efficiently while accommodating misalignments and reducing vibrations during high-speed operation.

These are just a few examples of the diverse applications of flexible couplings in various industries. Their ability to enhance power transmission efficiency, accommodate misalignments, and reduce vibrations makes them a versatile and indispensable component in modern machinery and equipment.

What are the factors influencing the thermal performance of a flexible coupling?

The thermal performance of a flexible coupling can be influenced by several factors, including:

- Material Composition: The material used in the construction of the flexible coupling can impact its thermal performance. Different materials have varying thermal conductivity and heat resistance properties, which can affect how well the coupling dissipates heat generated during operation.

- Operating Speed: The rotational speed of the flexible coupling can influence its thermal behavior. Higher speeds can result in increased friction, leading to more heat generation. Couplings designed for high-speed applications often incorporate features to manage and dissipate heat effectively.

- Power Transmission: The amount of power transmitted through the flexible coupling plays a role in its thermal performance. Higher power levels can lead to increased heat generation, and the coupling must be designed to handle and dissipate this heat without compromising its integrity.

- Environmental Conditions: The ambient temperature and surrounding environment can impact the thermal performance of the flexible coupling. In high-temperature environments, the coupling may need to dissipate heat more efficiently to avoid overheating.

- Lubrication: Proper lubrication is essential for managing friction and heat generation within the coupling. Insufficient or inappropriate lubrication can lead to increased wear and heat buildup.

- Design and Geometry: The design and geometry of the flexible coupling can influence its thermal performance. Some coupling designs incorporate features such as cooling fins, ventilation, or heat sinks to enhance heat dissipation.

- Load Distribution: The distribution of loads across the flexible coupling can affect how heat is generated and dissipated. Proper load distribution helps prevent localized heating and reduces the risk of thermal issues.

Manufacturers consider these factors during the design and selection of flexible couplings to ensure they can handle the thermal demands of specific applications. Proper application and maintenance of the flexible coupling are also essential for optimizing its thermal performance and overall efficiency.

What are the advantages of using flexible couplings in mechanical systems?

Flexible couplings offer several advantages in mechanical systems, making them essential components in various applications. Here are the key advantages of using flexible couplings:

- Misalignment Compensation: One of the primary advantages of flexible couplings is their ability to compensate for shaft misalignment. In mechanical systems, misalignment can occur due to various factors such as installation errors, thermal expansion, or shaft deflection. Flexible couplings can accommodate angular, parallel, and axial misalignment, ensuring smooth power transmission and reducing stress on the connected equipment and shafts.

- Vibration Damping: Flexible couplings act as damping elements, absorbing and dissipating vibrations and shocks generated during operation. This feature helps to reduce noise, protect the equipment from excessive wear, and enhance overall system reliability and performance.

- Torsional Flexibility: Flexible couplings provide torsional flexibility, allowing them to handle slight angular and axial deflections. This capability protects the equipment from sudden torque fluctuations, shock loads, and torque spikes, ensuring smoother operation and preventing damage to the machinery.

- Overload Protection: In case of sudden overloads or torque spikes, flexible couplings can absorb and distribute the excess torque, protecting the connected equipment and drivetrain from damage. This overload protection feature prevents unexpected failures and reduces downtime in critical applications.

- Reduce Wear and Maintenance: By compensating for misalignment and damping vibrations, flexible couplings help reduce wear on the connected equipment, bearings, and seals. This results in extended component life and reduced maintenance requirements, leading to cost savings and improved system reliability.

- Compensation for Thermal Expansion: In systems exposed to temperature variations, flexible couplings can compensate for thermal expansion and contraction, maintaining proper alignment and preventing binding or excessive stress on the equipment during temperature changes.

- Electric Isolation: Some types of flexible couplings, such as disc couplings, offer electrical isolation between shafts. This feature is beneficial in applications where galvanic corrosion or electrical interference between connected components needs to be minimized.

- Space and Weight Savings: Flexible couplings often have compact designs and low inertia, which is advantageous in applications with space constraints and where minimizing weight is crucial for performance and efficiency.

- Cost-Effectiveness: Flexible couplings are generally cost-effective solutions for power transmission and motion control, especially when compared to more complex and expensive coupling types. Their relatively simple design and ease of installation contribute to cost savings.

In summary, flexible couplings play a vital role in mechanical systems by providing misalignment compensation, vibration damping, overload protection, and torsional flexibility. These advantages lead to improved system performance, reduced wear and maintenance, and enhanced equipment reliability, making flexible couplings a preferred choice in various industrial, automotive, marine, and aerospace applications.

editor by CX 2023-12-25

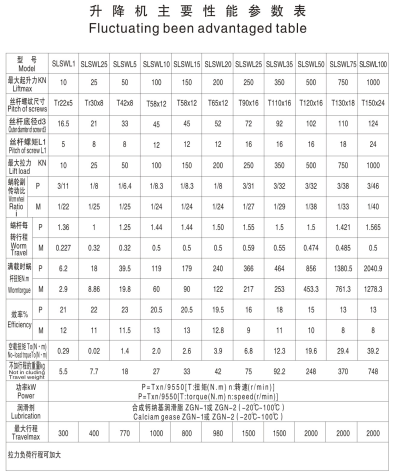

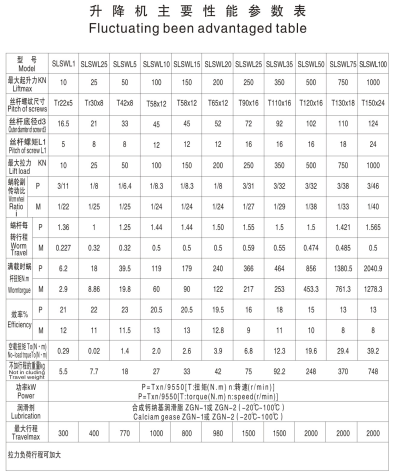

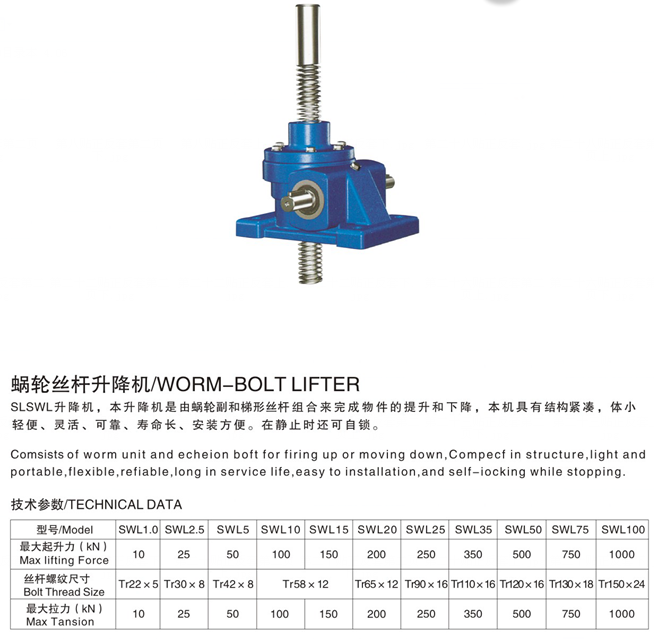

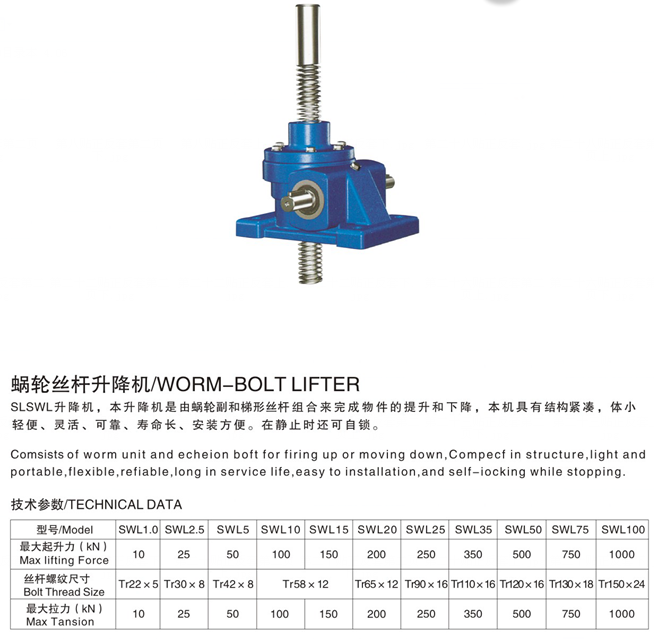

Best China manufacturer & factory SWL series worm gear nut travel 90 degree screw small lifting jacks for lifting motor speed reducer With high quality best price

We are aiming to meet the demands of the clients around the world.. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

worm

- Output Torque:

-

50~2300Nm

- Input Speed:

-

1400rpm

- Output Speed:

-

14-280rpm

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Certification:

-

ISO9001-2008

- Lifting Capacity:

-

As request

- LiftiEPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery cutting tools. ng Height(mm):

-

As request

- Overall Width(mm):

-

As request

- Gear material:

-

Low carbon high alloy steel

- Heat treatment:

-

Carburising, quenching, gear grinding

- Diameter & Length of Screw:

-

Designed as request

- Bearing:

-

C&U

- gear precision grade:

-

din 4

We get a lot of questions surrounding PTO shafts and how to attach them to your tractor. In today’s post, we’ll cover the basics of PTO, PTO Shafts, and PTO adapters for your tractor mounted implements. PTO stands for “Power Take-Off” and is the primary mechanism for providing power to an attachment or implement (such as a flail mower) via PTO shaft.By providing rotational energy through the driveshaft (or cardan shaft) a variety of tractor mounted implements can be operated by small and mid-sized tractors.

Supply Ability

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Standard exporting package

- Port

- Ningbo Port, Shanghai Port

Online Customization

SWL series worm gear nut travel 90 degree screw small lifting jacks for lifting motor speed reducer

Product Description

Advantage:

SWL Worm-bolt lifter has the features of compacted structure, light and portable, flexible, reliable, long service life, easy to installation, and self-locking while stop.

Application Industries:

SWL series screw jacks are widely used in industries such as metallurgy,mining,hoisting and transportation, electrical power,energy source, construction and building material,light industry and traffic industry

| Certification | ISO9001-2008 |

| Lifting Capacity | As request |

| Lifting Height(mm) | As request |

| Overall Width(mm) | As request |

| Gear material | Low carbon high alloy steel |

| Heat treatment | Carburising, quenching, gear grinding |

| Diameter & Length of Screw | Designed as request |

| Bearing | C&U |

| gear precision grade | din 4 |

Company Information

Certifications

Our Services

Packaging & Shipping

Related Products

FAQ

: Are you trading company or manufacturerTo eliminate contact-pattern inconsistencies, EPT developed an automated centering machine that accurately measures each worm and gear subassembly, as well as the reducer housing and bearing covers. A computer records the data and calculates the thickness and location of shims required to exactly center the gear under the worm shaft and, at the same time, provides the appropriate end 1play for the output tapered-roller bearings. This maximizes operating efficiency and minimizes temperature rise. ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact us

Best China manufacturer & factory reduction gearbox wpa worm gear reducer servo planetary gearbox screw jack lift electric motor transmissions rducteur cyclode With high quality best price

EPG has set up a complete set of quality management system whiIt was born in 1997, and is the fruit of the merger of different gearboxes brands. From the first products, it inherited a philosophy based in quality, profitability and technical rigor. EPG is present in all european market, through a complete distribution chain consisting of each market’s principal actors.ch is provided with advanced inspection and test equipment.

Our company has solid economic strength, builds up a technician team contingent with high quality, possesses the production assembly line of technicalization in China and perfect system checking on product quality and runs marketing networks throughout the country.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

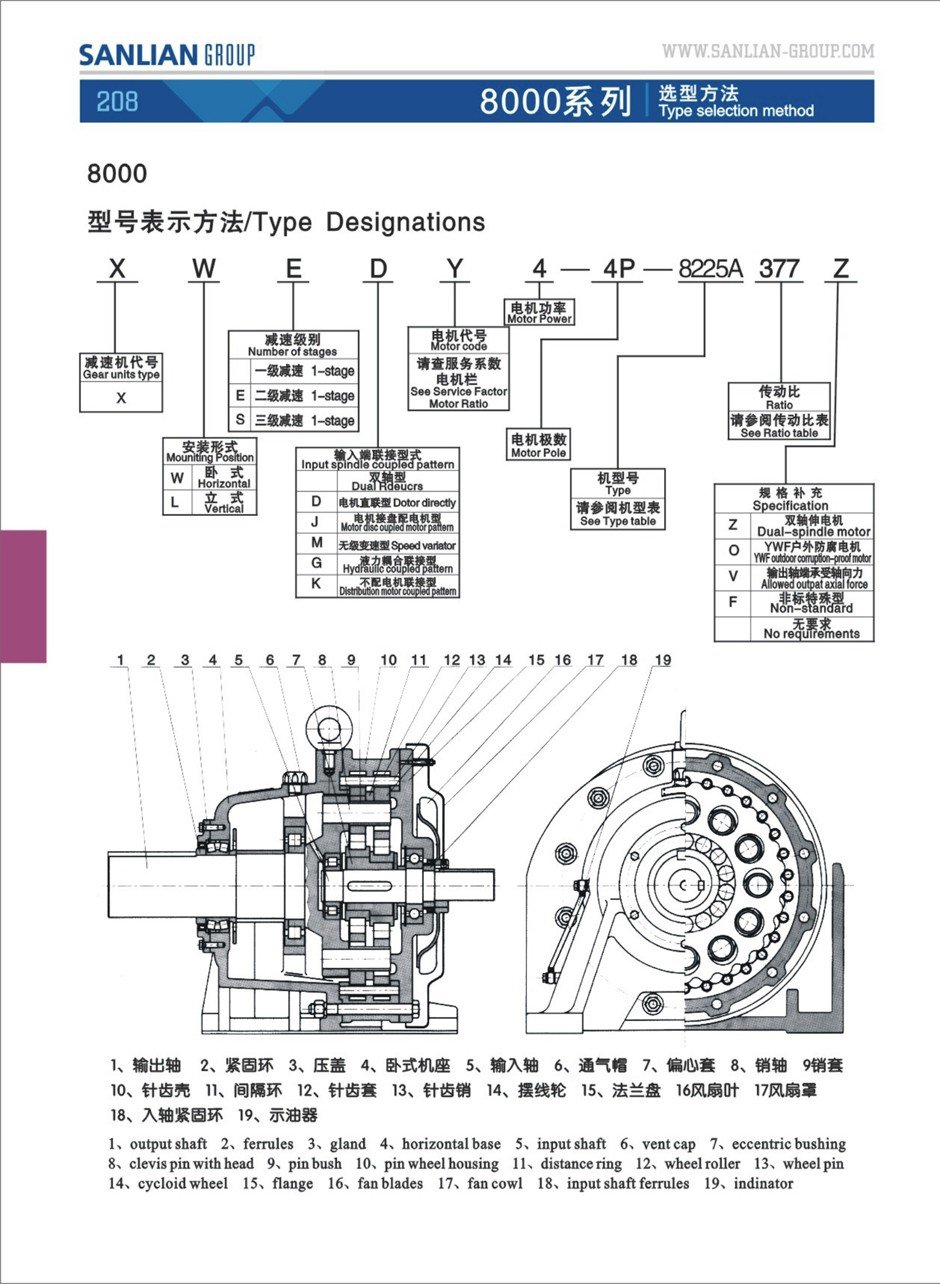

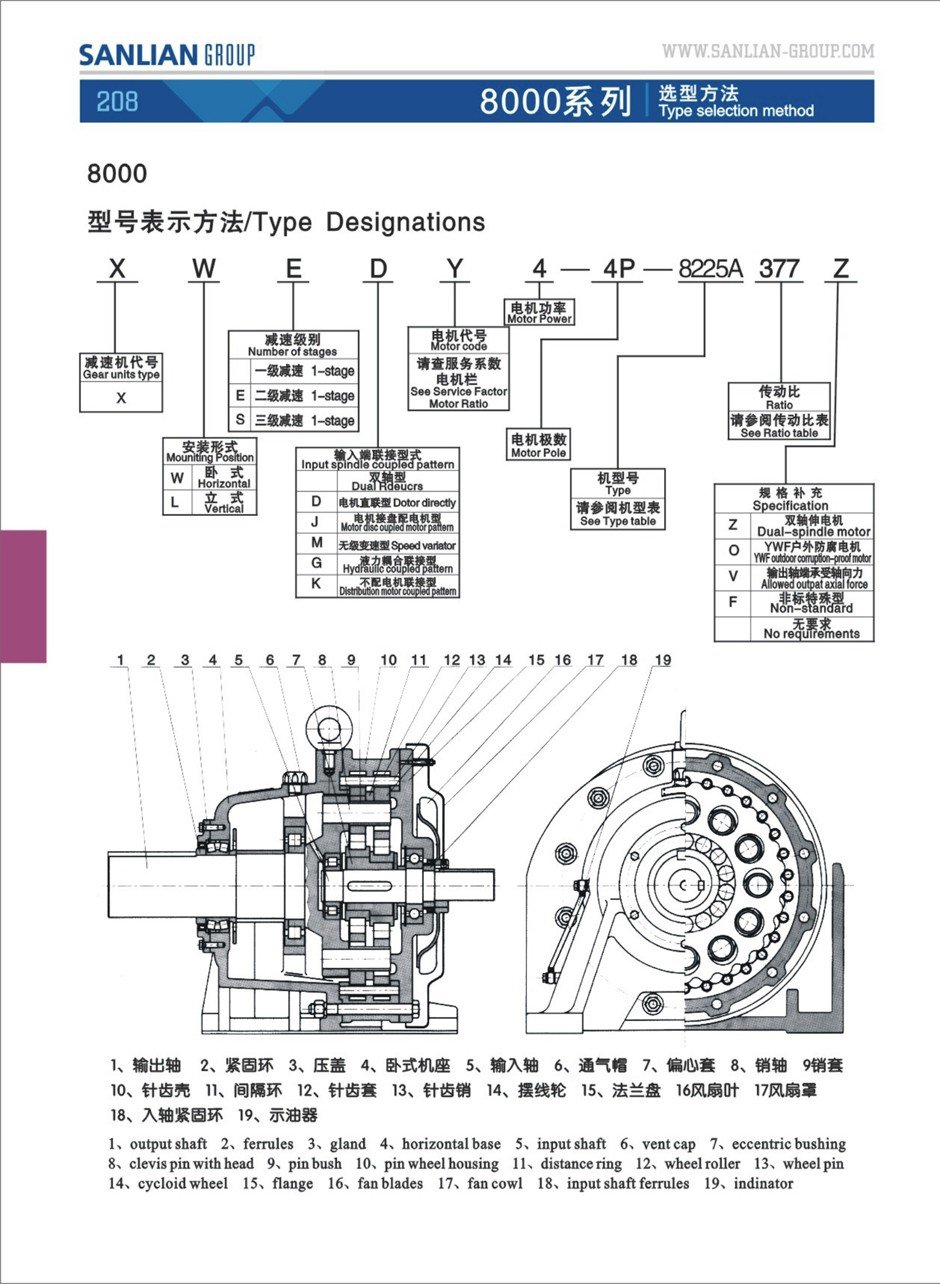

Cycloidal

- Output Torque:

-

70N.m~20000N.m

- Input Speed:

-

750-1500rpm

- Output Speed:

-

Our PTO drive shafts enable the user easy maintenance. The greasing nipples on standard crosses are positioned under angle to enable the user better access. Easier access is also possible because of the flexible cone. We listened to the wishes of our customers and placed the greasing nipple at wide-angle PTO’s into the cross bearing. The other novelty, we introduced with wide-angle PTO drive shafts is in line greasing. We wanted to additionally simplify the maintenance and extend the lifespan of joints.

0.3~136rpm

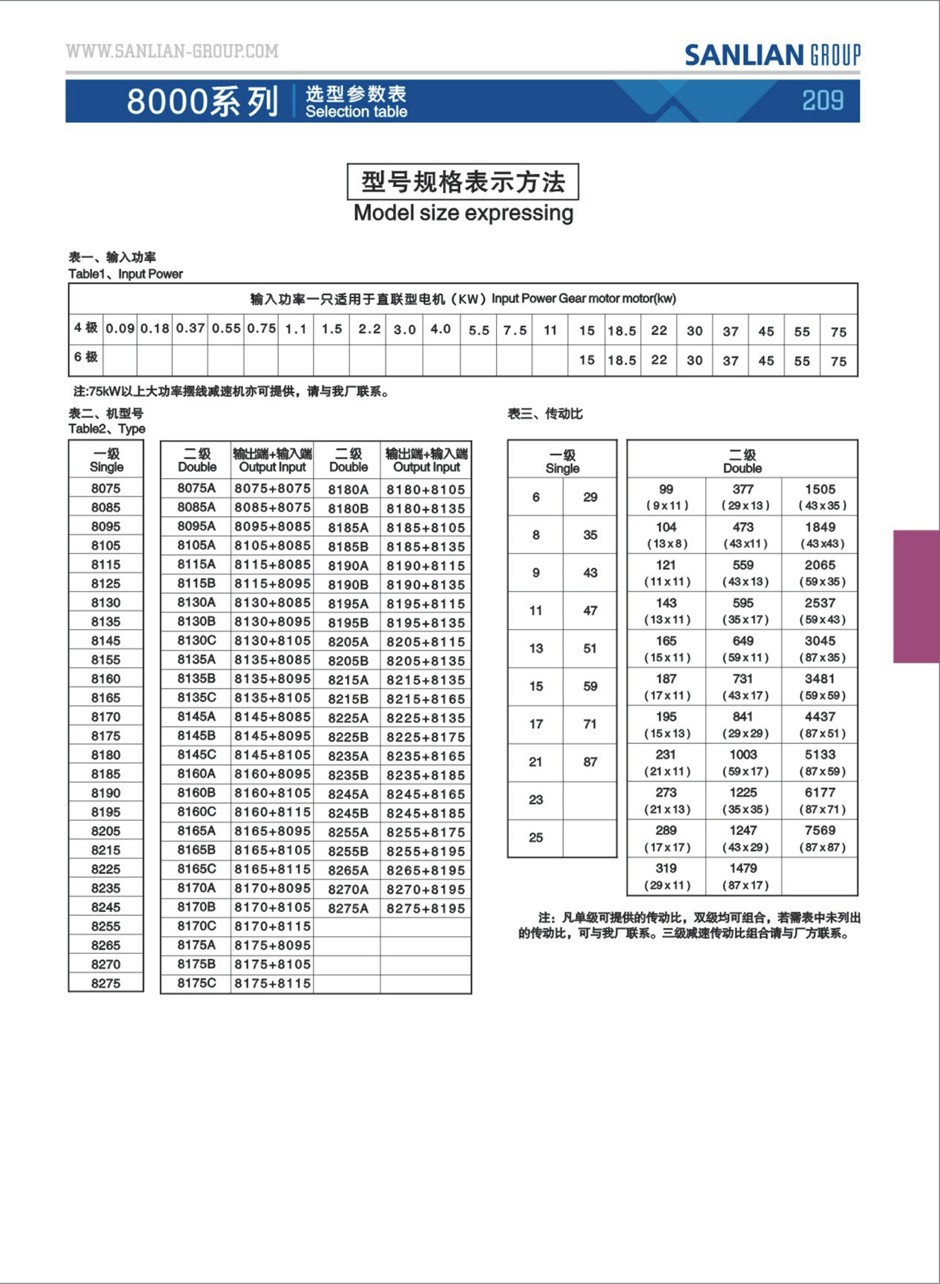

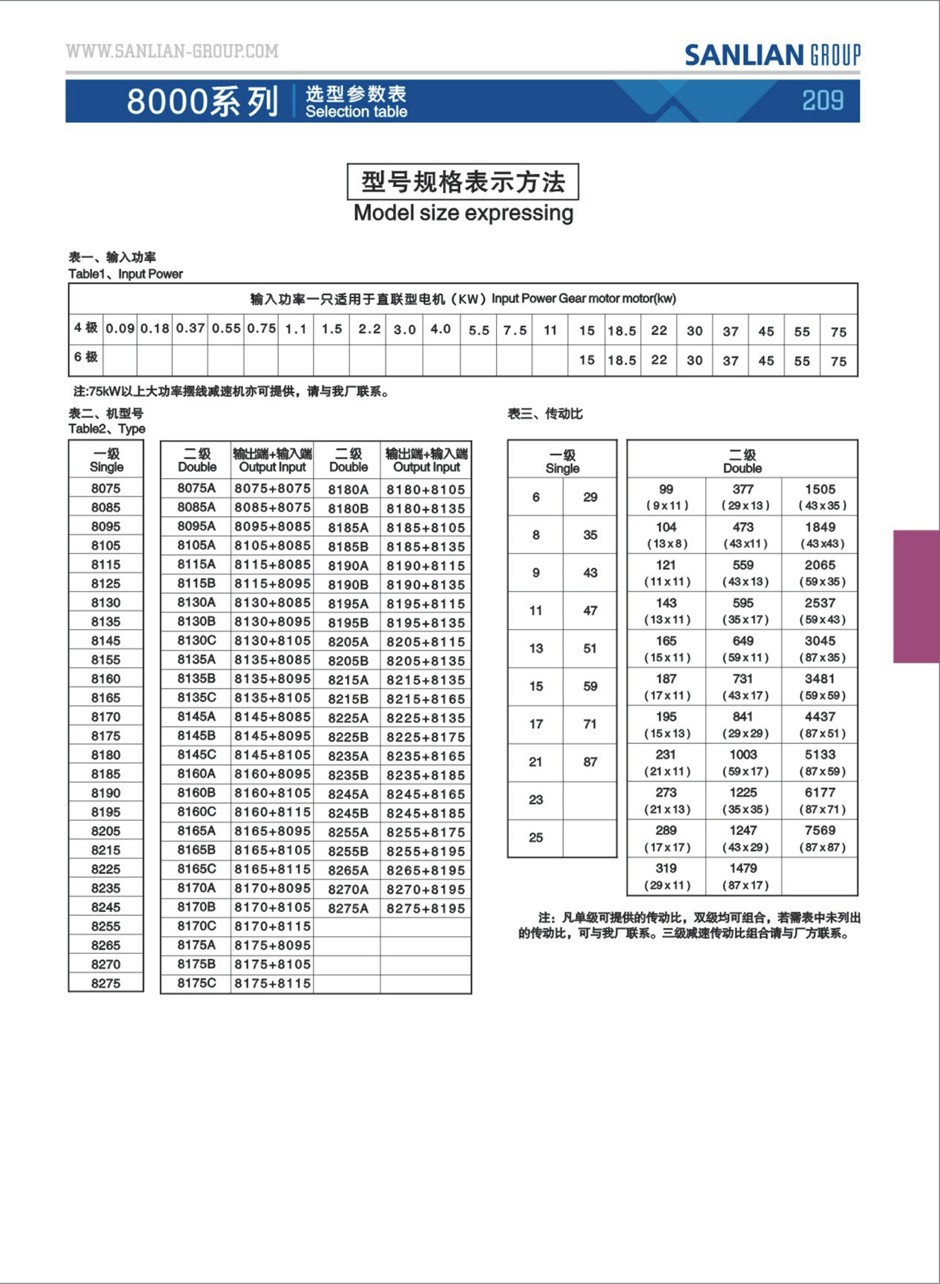

- Ratio:

-

6-5133

- Cycloidal Wheel:

-

Be grinded

- Certification:

-

ISO9001-2008

Supply Ability

- Supply Ability:

- 50000 Set/Sets per Year

Packaging & Delivery

- Packaging Details

- Stanard wooden case, or wooden pallet

- Port

- China Port

-

Lead Time

: -

Quantity(Boxes) 1 – 1 >1 Est. Time(days) 20 To be negotiated

Online Customization

Product Description

reduction gearbox wpa worm gear reducer servo planetary gearbox screw jack lift electric motor transmissions

Certifications

Trade Shows

Packaging & Shipping

Packing Details : Standard carton/Pallet/Standard wooden case

Delivery Details : 15-30 working days upon payment

Company Information

other series product

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Custom made Non-standard Gearbox | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series High Power Reducer |

| NMRV Series Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Related Products

Contact