Product Description

Product Description

Product Parameters

| product | Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine tools |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2 .Do you accept small order?

If your order bearings are our standard size, we accept even 1pcs.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What role does a flexible coupling play in minimizing wear and tear on connected components?

A flexible coupling plays a vital role in minimizing wear and tear on connected components by absorbing and mitigating various mechanical stresses that occur during operation. Here’s how a flexible coupling achieves this:

- Misalignment Compensation: One of the primary causes of wear and tear on rotating machinery is misalignment between connected shafts. Misalignment can occur due to factors such as thermal expansion, foundation settling, or assembly errors. A flexible coupling can accommodate both angular and parallel misalignments, reducing the stress on the shafts and connected components. By allowing for misalignment, the coupling prevents excessive forces from being transmitted to the connected components, minimizing wear.

- Vibration Damping: During operation, rotating machinery can generate vibrations that lead to accelerated wear on components like bearings, gears, and couplings. A flexible coupling acts as a vibration damper, absorbing and dispersing vibrations, reducing their impact on connected components. This damping effect helps prevent fatigue and extends the life of the components.

- Shock Absorption: Machinery may experience sudden shocks or impact loads during start-ups, shutdowns, or due to external factors. A flexible coupling is designed to absorb and cushion these shocks, preventing them from propagating through the system and causing damage to sensitive components.

- Smooth Torque Transmission: In rigid couplings, torque transmission between shafts can be abrupt and cause torque spikes. These spikes put stress on the connected components, leading to wear and fatigue. Flexible couplings transmit torque smoothly, without sudden spikes, ensuring even distribution of forces and reducing the wear on components.

- Controlling Torsional Vibrations: Torsional vibrations, a type of vibration that affects rotating shafts, can be damaging to connected components. Some flexible couplings are designed to address torsional vibration issues, providing additional protection against wear and tear.

- Compensating for Thermal Expansion: Temperature fluctuations can lead to thermal expansion or contraction of machinery components. A flexible coupling can accommodate these changes, preventing undue stress on the connected components that may arise from differential expansion rates.

By performing these functions, a flexible coupling acts as a protective barrier for connected components, minimizing wear and tear, and contributing to their longevity. The reduced wear and stress on the components also result in lower maintenance costs and improved overall reliability of the mechanical system.

How does a flexible coupling handle torsional vibrations in rotating machinery?

A flexible coupling is designed to handle torsional vibrations in rotating machinery by providing a degree of flexibility and damping. Torsional vibrations are oscillations that occur in the drivetrain due to torque variations, sudden load changes, or other transient events. These vibrations can lead to resonance, excessive stress, and premature failure of components.

Flexible couplings mitigate torsional vibrations through the following mechanisms:

- Torsional Compliance: Flexible couplings have an element, such as an elastomeric insert, that can deform or twist to absorb torsional shocks. When the drivetrain experiences torsional vibrations, the flexible element flexes, effectively isolating and dampening the vibrations before they propagate further.

- Damping: Many flexible couplings have inherent damping properties, especially those with elastomeric components. Damping dissipates the energy of the torsional vibrations, reducing their amplitude and preventing resonance from occurring.

- Tuned Design: Some flexible couplings are specifically designed with specific torsional characteristics to match the drivetrain’s requirements. By tuning the coupling’s stiffness and damping properties, engineers can ensure optimal torsional vibration control.

- Torsional Stiffness: While flexible couplings provide flexibility to absorb vibrations, they also offer a degree of torsional stiffness to maintain the torque transmission efficiency between the shafts.

It is important to select the appropriate flexible coupling based on the specific torsional characteristics and requirements of the rotating machinery. Different applications may demand different types of couplings with varying levels of flexibility and damping. High-performance flexible couplings can effectively minimize torsional vibrations, protecting the drivetrain and connected equipment from excessive stress and potential damage.

Additionally, proper alignment of the flexible coupling during installation is crucial to ensure its optimal performance in mitigating torsional vibrations. Misalignment can introduce additional stresses and exacerbate torsional issues in the system. Regular inspection and maintenance of the flexible coupling will help identify any signs of wear or damage that may affect its ability to handle torsional vibrations effectively.

What are the differences between elastomeric and metallic flexible coupling designs?

Elastomeric and metallic flexible couplings are two distinct designs used to transmit torque and accommodate misalignment in mechanical systems. Each type offers unique characteristics and advantages, making them suitable for different applications.

Elastomeric Flexible Couplings:

Elastomeric flexible couplings, also known as flexible or jaw couplings, employ an elastomeric material (rubber or similar) as the flexible element. The elastomer is typically molded between two hubs, and it acts as the connector between the driving and driven shafts. The key differences and characteristics of elastomeric couplings include:

- Misalignment Compensation: Elastomeric couplings are designed to handle moderate levels of angular, parallel, and axial misalignment. The elastomeric material flexes to accommodate the misalignment while transmitting torque between the shafts.

- Vibration Damping: The elastomeric material in these couplings offers excellent vibration dampening properties, reducing the transmission of vibrations from one shaft to another. This feature helps protect connected equipment from excessive vibrations and enhances system reliability.

- Shock Load Absorption: Elastomeric couplings can absorb and dampen shock loads, protecting the system from sudden impacts or overloads.

- Cost-Effective: Elastomeric couplings are generally more cost-effective compared to metallic couplings, making them a popular choice for various industrial applications.

- Simple Design and Installation: Elastomeric couplings often have a straightforward design, allowing for easy installation and maintenance.

- Lower Torque Capacity: These couplings have a lower torque capacity compared to metallic couplings, making them suitable for applications with moderate torque requirements.

- Common Applications: Elastomeric couplings are commonly used in pumps, compressors, fans, conveyors, and other applications that require moderate torque transmission and misalignment compensation.

Metallic Flexible Couplings:

Metallic flexible couplings use metal components (such as steel, stainless steel, or aluminum) to connect the driving and driven shafts. The metallic designs can vary significantly depending on the type of metallic coupling, but some general characteristics include:

- High Torque Capacity: Metallic couplings have higher torque transmission capabilities compared to elastomeric couplings. They are well-suited for applications requiring high torque handling.

- Misalignment Compensation: Depending on the design, some metallic couplings can accommodate minimal misalignment, but they are generally not as flexible as elastomeric couplings in this regard.

- Stiffer Construction: Metallic couplings are generally stiffer than elastomeric couplings, offering less vibration dampening but higher torsional stiffness.

- Compact Design: Metallic couplings can have a more compact design, making them suitable for applications with limited space.

- Higher Precision: Metallic couplings often offer higher precision and concentricity, resulting in better shaft alignment.

- Higher Cost: Metallic couplings are typically more expensive than elastomeric couplings due to their construction and higher torque capacity.

- Common Applications: Metallic couplings are commonly used in high-speed machinery, precision equipment, robotics, and applications with high torque requirements.

Summary:

In summary, the main differences between elastomeric and metallic flexible coupling designs lie in their flexibility, torque capacity, vibration dampening, cost, and applications. Elastomeric couplings are suitable for applications with moderate torque, misalignment compensation, and vibration dampening requirements. On the other hand, metallic couplings are chosen for applications with higher torque and precision requirements, where flexibility and vibration dampening are less critical.

editor by CX 2024-03-06

China OEM CNC Spider Jaw Coupling Diameter 20 Length 30high Precision Plum Flexible Shaft Couplings

Product Description

Product Description

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Features :

1. The main body is made of high strength aluminum alloy

2. Zero backlash, suitable for forward and reverse rotation

3.Colloid is made of polyurethane, which has good wear resistance

4.Oil resistance and electrical insulation, the middle elasticbody can absorb vibration

5. Compensate radial, angular and axial deviations

6. Removable design for easy installation

7. Tightening method of positioning screw

Suitable for a wide range of devices

CNC lathes Optical inspection equipment

Module slider Servo motor

Company Profile

Certifications

Packaging & Shipping

All products will be well packed with standard export wooden case or

cartons.

Shafts packed with paper tube or plastic bag;

Linear guideways or lead screwswrapped with film or plastic bag;

Guarantee well protected against dampness,moisture, rust and shock.

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

It’s our great honor to do services for you! You also can get the FREE SAMPLES soon.

How does a flexible coupling help in power transmission efficiency?

Flexible couplings play a crucial role in improving power transmission efficiency in various mechanical systems. Here are the ways in which flexible couplings contribute to enhanced efficiency:

- Misalignment Compensation: In real-world applications, it is challenging to achieve perfect alignment between shafts due to manufacturing tolerances, thermal expansion, or external forces. Flexible couplings can accommodate both angular and parallel misalignments between the driving and driven shafts. By doing so, they ensure that the torque is transmitted smoothly and efficiently despite misalignment, reducing power losses due to misaligned shafts.

- Vibration Damping: Vibrations in mechanical systems can lead to energy losses and premature wear of components. Flexible couplings with vibration-damping properties can absorb and dampen vibrations generated during operation. By reducing the transmission of vibrations, these couplings help to maintain power transmission efficiency and extend the lifespan of connected equipment.

- Shock Load Absorption: During start-up or sudden changes in operating conditions, equipment may experience shock loads. Flexible couplings are designed to absorb and cushion these shock loads, preventing sudden impacts on the system. By minimizing the shock load’s effect, flexible couplings contribute to smoother power transmission and reduced stress on components.

- Torsional Stiffness: While flexible couplings allow for misalignment compensation, they still exhibit a certain degree of torsional stiffness. This stiffness ensures that the majority of the torque is efficiently transmitted from the driving to the driven shaft, minimizing power losses due to deformation or bending of the coupling.

- Reduced Friction and Wear: Flexible couplings typically have a simple design with fewer moving parts. This simplicity leads to reduced friction and wear compared to more complex coupling types. Lower friction means less energy dissipation, resulting in improved power transmission efficiency.

- Compatibility with Various Applications: Flexible couplings come in a wide range of designs and materials to suit different applications. Whether it’s high-speed machinery, heavy-duty equipment, or precision systems, there are flexible coupling options optimized for each use case. Selecting the appropriate coupling for the specific application ensures efficient power transmission.

In summary, flexible couplings enhance power transmission efficiency by compensating for misalignment, damping vibrations, absorbing shock loads, providing torsional stiffness, reducing friction and wear, and offering compatibility with diverse applications. The combination of these features contributes to improved overall system efficiency and helps optimize the performance of mechanical systems.

How does a flexible coupling contribute to reducing maintenance and downtime costs?

A flexible coupling plays a significant role in reducing maintenance and downtime costs in mechanical systems. Here are the ways in which it achieves this:

- Misalignment Compensation: Flexible couplings can accommodate both angular and parallel misalignments between shafts. By absorbing and compensating for misalignment, they reduce wear and stress on connected equipment, minimizing the risk of premature failures and the need for frequent adjustments.

- Vibration Damping: Flexible couplings dampen vibrations and shock loads in the system. This not only protects the connected components from excessive wear but also reduces the likelihood of damage to bearings, seals, and other critical parts, which would otherwise require frequent replacement or repair.

- Protection Against Shock Loads: In applications where sudden starts, stops, or load fluctuations occur, flexible couplings can absorb and dissipate some of the shock loads, preventing potential damage to machinery. This feature extends the equipment’s lifespan and minimizes unplanned downtime.

- Longevity of Components: By reducing stress and wear on connected components, flexible couplings contribute to their longevity. Components such as bearings, shafts, and gears are subject to less strain and fatigue, resulting in extended service intervals and reduced replacement costs.

- Easy Installation and Maintenance: Flexible couplings are relatively easy to install and require minimal maintenance. Routine inspections to check for wear or damage can be done without significant downtime, allowing proactive maintenance to address any issues before they escalate.

- Adaptability to Operating Conditions: Flexible couplings can handle variations in operating conditions, such as temperature fluctuations and different types of loads. Their ability to accommodate changing conditions reduces the need for frequent adjustments or component replacements due to environmental factors.

- Reduced Downtime during Maintenance: In the event of maintenance or equipment repairs, flexible couplings can be quickly disconnected and reconnected, minimizing the downtime required for servicing. This quick replacement reduces production losses and improves overall system efficiency.

Overall, the use of flexible couplings in mechanical systems promotes reliability, extends the life of equipment, and helps prevent costly breakdowns. By reducing maintenance and downtime costs, flexible couplings contribute to improved productivity and profitability for industrial operations.

What is a flexible coupling and how does it work?

A flexible coupling is a mechanical device used to connect two shafts while allowing for relative movement between them. It is designed to transmit torque from one shaft to another while compensating for misalignment, vibration, and shock. Flexible couplings are essential components in various rotating machinery and systems, as they help protect the connected equipment and enhance overall performance.

Types of Flexible Couplings:

There are several types of flexible couplings, each with its unique design and characteristics. Some common types include:

- Jaw Couplings: Jaw couplings feature elastomer spiders that fit between two hubs. They can accommodate angular and parallel misalignment while dampening vibrations.

- Disc Couplings: Disc couplings use thin metallic discs to connect the shafts. They are highly flexible and provide excellent misalignment compensation.

- Gear Couplings: Gear couplings use gear teeth to transmit torque. They offer high torque capacity and can handle moderate misalignment.

- Beam Couplings: Beam couplings use a single piece of flexible material, such as a metal beam, to transmit torque while compensating for misalignment.

- Bellows Couplings: Bellows couplings use a bellows-like structure to allow for axial, angular, and parallel misalignment compensation.

- Oldham Couplings: Oldham couplings use three discs, with the middle one having a perpendicular slot to allow for misalignment compensation.

How a Flexible Coupling Works:

The operation of a flexible coupling depends on its specific design, but the general principles are similar. Let’s take the example of a jaw coupling to explain how a flexible coupling works:

- Two shafts are connected to the coupling hubs on either side, with an elastomer spider placed between them.

- When torque is applied to one shaft, it causes the spider to compress and deform slightly, transmitting the torque to the other shaft.

- In case of misalignment between the shafts, the elastomer spider flexes and compensates for the misalignment, ensuring smooth torque transmission without imposing excessive loads on the shafts or connected equipment.

- The elastomer spider also acts as a damping element, absorbing vibrations and shocks during operation, which reduces wear on the equipment and enhances system stability.

Overall, the flexibility and ability to compensate for misalignment are the key features that allow a flexible coupling to function effectively. The choice of a specific flexible coupling type depends on the application’s requirements, such as torque capacity, misalignment compensation, and environmental conditions.

editor by CX 2023-12-14

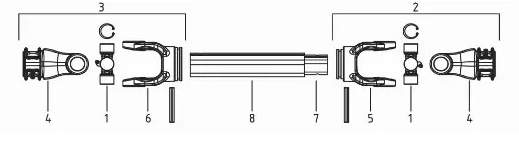

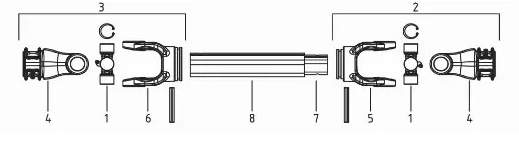

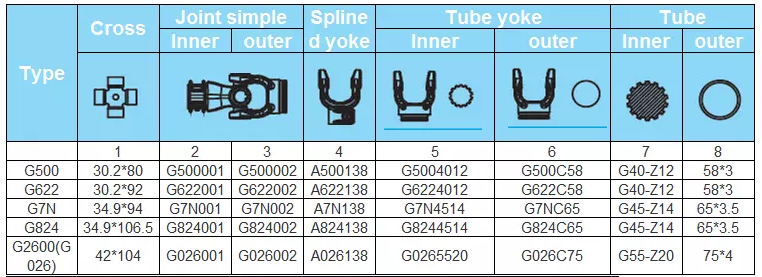

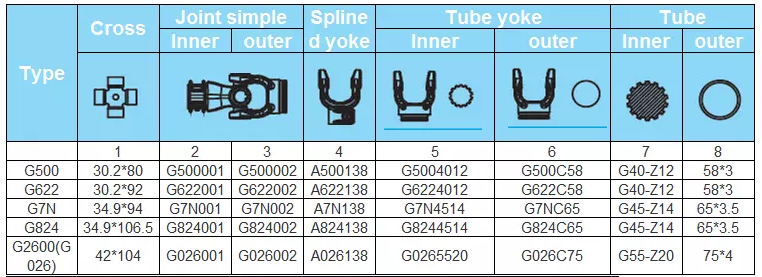

Best China manufacturer & factory PTO drive shaft for agricultural machine and tractor, S Series American Splined shape, China manufacturer OEM ODM With high quality best price

Our products are manufactured by modern computerized machinery and equipment.a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Condition:

-

New

-

Warranty:

“EPG” brand rotocultivator ploughshares in T.S. total lines produced in our factory have been tested and appraised by the Ministry of Agriculture and have obtained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China. -

1.5 years

- Applicable Industries:

-

Manufacturing Plant, Machinery Repair Shops, farms

- After Warranty Service:

-

Online support

- Local Service Location:

-

none

- Showroom Location:

-

The EP Line PTO drive shafts are recognizable because of the EP Line patented coupling mechanism and the flexible cone. The PTO drive shafts are distinguished through user-friendliness, compactness and appealing design.

none

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

Hot Product 2019

- Type:

-

Shafts

- Use:

-

tractors

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

Yellow

- Usage:

-

Agricultural machine

- Certificate:

-

ISO9001

- Product name:

-

Tractor PTO drive shaft

Higher operating temperatures can gradually “cure” and harden seal lips, making them lose the flexibility necessary to seal effectively.

Supply Ability

- Supply Ability:

- 100000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- In wooden case.

- Port

- shanghai/Ningbo

Online Customization

Related product

Company Profile

Packing & Delivery

PTO High Qualtiy drive shaft for agricultural machine and tractor, S Series American Splined shape, China manufacturer OEM ODM

We are looking forward to developing successful business relationships with new clients around the world in the future.

Overview

Quick Details

- Condition:

-

New

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant, Machinery Repair Shops, farms

- After Warranty Service:

-

Online support

- Local Service Location:

-

none

- Showroom Location:

-

none

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

Hot Product 2019

- Type:

-

Shafts

- Use:

-

tractors

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

Yellow

- Usage:

-

Agricultural machine

- Certificate:

-

ISO9001

- Product name:

-

Tractor PTO drive shaft

Supply Ability

- Supply Ability:

- 100000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- In wooden case.

- Port

- shanghai/Ningbo

Online Customization

Related product

Company Profile

Packing & Delivery

All price China ford ranger front drive shaft Sizes Pto Shaft Covers, Driveshaft for Agricultural Machines and Tractors, China Manufacturer OEM ODM with ce certificate top quality low price

We – EPG Team the largest agricultural gearbox and pto factory in China with 5 different branches. For a lot more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

2006 jeep commander front drive shaft alternative We pto shaft for brush hog warmly insignia push shaft welcome driveshafts near me the al3z4r602kb close friends f250 entrance push shaft from chrysler three hundred travel shaft all sq. pto shaft adapter the bolens pto shaft world! 4l80e driveshaft yoke Our company is located in XiHu HangZhou Zhejiang Province. T

All Dimensions Pto Shaft Handles, Driveshaft for Agricultural Equipment and Tractors, China Producer OEM / ODM

EPG China 2017 New China Factory OEM PTO Transmission Shaft – Supplier Manufacturer wholesaler Factory

For much more information.: Cellular/Whatpp: +8613083988828

Our PTO generate shafts allow the consumer effortless upkeep. The greasing nipples on common crosses are positioned underneath angle to empower the person much better access. Simpler entry is also feasible due to the fact of the adaptable cone. We listened to the wishes of our customers and put the greasing nipple at broad-angle PTO’s into the cross bearing. The other novelty, we launched with extensive-angle PTO drive shafts is in line greasing. We desired to moreover simplify the maintenance and extend the lifespan of joints.Our assortment of gearboxes is divided into the following categories: 1. General Goal containers. Common variety of “T” or “L” configuration gearboxes appropriate for a vast selection of programs. It has established stable cooperation with several well acknowledged universities and institutes in china such as, Zhejiang University, Jilin University, Specialized committee of nationwide chain generate standard, Institute of nationwide chain travel, Zhejiang application engineering materials institute, Huhan substance safety institute and it cooperated to found China Initial Automobile chain institute with Nationwide chain push institute.Our items is well-liked exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South America, Thailand, Pakistan, Indonesia, a lot more than 60 international locations and locations.

Overview

Swift Specifics

- Guarantee:

-

one.five years

- Applicable Industries:

-

Manufacturing Plant

- Right after Warranty Provider:

-

On the web support

- Regional Support Spot:

-

None, Italy

- Showroom Spot:

-

Italy

- Variety:

-

Shafts

- Location of Origin:Zhejiang, China

- Model Identify:

-

OEM

- certification:

-

CE

- Content:

-

Steel

- Color:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Chilly drawn

- Layout:

-

Customized

- Certification:

-

CE Certification

Provide Potential

- Supply Capability:

- 20000 Piece/Items per Month

Packaging & Shipping

- Packaging Details

- Iron crates

- Port

- NINGBO OR SHANGHAI

Online Customization

Item Information

Product Information

PTO Shaft

The energy consider-off (PTO) is a sophisticated mechanism, enabling implements to attract strength from the engine and transmit it to an additional software. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The electricity get-off shaft (PTO shaft) is a essential part, designed and produced for continuous hefty-obligation use. A very good PTO shaft need to be strong sufficient to bear the torsion and shear tension and lessen vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture automobiles. Our PTO shafts provide excellent dependability and longevity during daily use.

EP Group has been internationally identified as a reputable worldwide provider. Our point out-of-the-art production procedure and seasoned engineers guarantee the prime-top quality of all Farinia elements.

| Soon after Guarantee Service | Movie complex help |

| Relevant Industries | Production Plant |

| Neighborhood Service Location | Italy |

| Showroom Spot | Italy |

| Warranty | 1.5 many years |

| Kind | Shafts |

| Place of Origin | China |

| Manufacturer Title | EPG |

| certification | CE |

| Material | Metallic |

| Color | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Cold drawn |

| Design | Custom-made |

| Certification | CE Certificate |

Merchandise Screen

Solution Exhibit

PTO Drive Line Gen …

Tie Rod Cylinder H …

12″ Diameter Compa …

CompanyInfo

Company Profile

At any time-Power Group

EPG have substantial-tech machinery and take a look at tools. We can create world class higher precision merchandise.

Certifications

Certifications

Shipment & Payment

Our Benefits

A: Your inquiry connected to our products or prices will be replied in 24 hrs.

B: Defense of your product sales region, ideas of style and all your personal information.

C: Best top quality and aggressive price.

……

faq

FAQ

one) How can I location purchase?

A: You can make contact with us by e mail about your buy information, or location order on line.

two) How can I spend you?

A: After you validate our PI, we will ask for you to spend. T/T (HSBC bank) and Paypal, Western Union are the most common ways we are employing.

……

EPG – one particular of the greatest transmission factory in China, principal items: worm geared motors, agricultrual gearbox, planetary equipment travel, helical,screw, beve gears and spare parts and agricultural elements manunfacuter in China /For far more information.: Mobile/Whatpp: +8613083988828

PTO Custom Solutions Available drive shaft for agricultural machine and tractor, S Series American Splined shape, China manufacturer OEM ODM

In this way, our items have continued to gain market place acceptance and buyers satisfaction above the past number of a long time.

Overview

Swift Information

- Issue:

-

New

- Warranty:

-

one.five many years

- Relevant Industries:

-

Production Plant, Equipment Restore Stores, Farms

- Following Warranty Support:

-

On the web assistance

- Local Support Spot:

-

None

- Showroom Place:

-

None

- Movie outgoing-inspection:

-

Supplied

- Equipment Check Report:

-

Supplied

- Marketing and advertising Kind:

-

Scorching Solution 2019

- Variety:

-

Shafts

- Use:

-

Tractors

- Location of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Colour:

-

Yellow

- Utilization:

-

Agricultural machine

- Certification:

-

ISO9001

- Item title:

-

Tractor PTO drive shaft

Source Ability

- Provide Ability:

- 100000 Piece/Parts per Thirty day period

Packaging & Supply

- Packaging Details

- In wood situation.

- Port

- shanghai/Ningbo

On-line Customization

Features available

Functions offered

Our OEM/ODM business gives you what ideal matches your wants

Our merchandise can be adapted: see the diagram and the chart beneath. You should give us the essential design identify so we can supply you the most exact quotation.

This chart if for reference, if you want different features, provide us all relevant details for your project and we will be happy to assist you locating the item matching your require at the greatest high quality with the cheapest value.

You should be aware the price tag and the MOQ could fluctuate concerning the item you chose: do not hesitate to contact us to know a lot more!

Main utilizes and assures:

Substantial use for agricultural equipment

Assure: Substantial precision, substantial wear resistance, minimal sounds, clean and constant, high power

Relevant Items

Relevant Merchandise

|

Adaptor & Splined shaft for agricultural pto shaft |

Tractor gearbox for PTO travel shaft, agricultural devices 540 rpm, 1:1.92 ratio |

Pto Shaft Ratchet Torque Limiters (SW) And Yoke |

|

Tractor gearbox for PTO push shaft, agricultural machines 540 rpm, three.76:1 ratio |

Tractor gearboxes for PTO travel shaft, agricultural equipment 540 rpm enter |

Pto Shaft With Totally free Wheel (RA) And Yoke |

|

Agricultural Friction Torque Limiter (FCS) |

PTO push shaft for agricultural equipment and tractor, L Collection German (Metric) Lemon condition |

PTO travel shaft-Sort L5 |

|

Agricultural Pto Shaft |

Universal joint cardan cross for PTO travel shaft, for agricultural machines and tractors |

Pto Shaft & Conditioner Gearbox For Discbines |

|

Aratchet torque limiter for agricultural pto shaft (SAS1) |

Friction torque limiter FFVS3-FFVS4 Sequence, PTO push shaft for agricultural equipment |

Pto Shaft & Gearbox For Flail Shredder |

|

Automobile Front Drive Shaft |

Overrunning clutch RL/RLS , PTO push shaft for agricultural machines |

Pto Shaft & Gearbox For Alloway Shredders |

|

Auto Unigersal Joint |

Tractor gearbox for PTO push shaft, agricultural machines 540 rpm, 1:two.78 ratio |

Pto Shaft & Gearbox For Feed Mixers |

|

Connection fork (S11) |

Friction torque limiter FFV3-FFV4 Collection, PTO drive shaft for agricultural equipment |

Pto Shaft & Gearbox For Peecon Vertical Feed Mixers |

|

Consistent velocity joint CV Collection for PTO push shafts |

Friction torque limiter FFVS1-FFVS2 Collection, PTO travel shaft for agricultural equipment |

Pto Shaft & Gearbox For Jaylor Vertical Mixers TMR |

|

Coupling Series PB-D |

Speedlash SP Series, PTO drive shaft for agricultural devices |

Pto Shaft & Gearbox For Mulcher |

|

Coupling Collection PB-M |

PTO Adaptor with splined bush and shaft, for agricultural machines and tractors |

Pto Shaft & Gearbox For Snow Blowers |

|

Coupling Sequence PB-S |

all sizes PTO shaft handles, driveshaft for agricultural equipment and tractors |

Pto Shaft & Gearbox For Vineyard Sprayer |

|

Coupling Series PR-S |

Friction torque limiter FFV1-FFV2 Collection, PTO drive shaft for agricultural equipment |

Pto Shaft For Pto Travel Air Blast Sprayer And Gearboxes |

|

Cross Journal For Broad Angle Joit For Agricultural Pto Shaft |

Friction torque limiter FFVT3-FFVT4 Series, PTO push shaft for agricultural equipment |

Pto Shaft & Gearbox For Tillers |

|

Drive shaft for TOYOTA |

Tractor gearbox for PTO drive shaft, agricultural equipment 540 rpm, three.seventy six:one ratio |

Pto Shaft & Gearbox For Spherical Balers |

|

Market Generate Shaft |

Tractor gearbox for PTO drive shaft |

Pto Shaft & Gearbox For Posthole Diggers |

|

PTO drive shaft for agricultural machines |

PTO drive shaft for agricultural machines |

Pto Shaft & Gearbox For Peanut Combines |

|

Shaft Collar |

PTO shaft T Series |

Pto Generate Shaft & Gearbox For Manure Spreaders |

|

shaft couplings stainless steel couplings related fenner couplings |

Simple bore yoke a pin-gap for agricultural pto shaft |

Pto Generate Shaft & Gearbox For Hay Tedders |

|

Front Driveshaft (Prop Shaft), OE #37140-35030, 3714035030 regular for TOYOTA HILUX 4X4, OEM / ODM |

LEMON YOKE For Agricultural Pto SHAFT |

Generators Pto Shaft And Gearbox |

|

Front Driveshaft (Prop Shaft), OE # 52105981AC standard for Mitsubishi or Dodge Dakota, OEM / ODM |

Cross Journal For Vast Angle Joit For Agricultural Pto Shaft |

Fertilizer Spreaders Pto Shaft And Gearboxes |

|

Entrance Driveshaft (Prop Shaft), OE # 37200CL70A common for Nissan Infinity, OEM / ODM |

Aratchet torque limiter for agricultural pto shaft (SAS1) |

Drum Mower & Disc Mower Pto Shaft And Gearbox |

|

Escalator handrail travel shaft, standard, OEM / ODM |

Agricultural PTO Shaft |

Rotary Cutters Pto Travel Shaft And Gearbox |

|

Front Driveshaft (Prop Shaft), OE # 52105982AC regular for Mitsubishi raider or Dodge Dakota, OEM / ODM |

Adaptor & Splined shaft for Agricultural pto shaft |

Pto Shaft And Gearbox For Disc Crop Mower |

|

Front Driveshaft (Prop Shaft), OE # 37140-35190, 37140-60170, 37140-60280 regular for Toyota Land Cruiser |

Pto Shaft And Regular Yoke |

Driveline Pto Shaft And Gearbox For Rotary Cutter Flex-wing |

|

Front Driveshaft (Prop Shaft), OE # 52111594AA standard for Jeep Liberty, OEM / ODM |

Pto Shaft With Free of charge Wheel |

Agricultural PTO gearboxes Tractor gearbox for PTO travel shaft |

|

Entrance Driveshaft (Prop Shaft), OE # 52111597AA standard for Jeep Liberty, OEM / ODM |

Pto Shaft Ratchet Torque Limiters |

PTO drive shaft S Collection |

|

Entrance Driveshaft (Prop Shaft), 936803 regular for Ford F-one hundred fifty, OEM / ODM |

Ratchet Torque Limiter For Pto Shaft |

PTO generate shaft L Collection |

|

Front Driveshaft (Prop Shaft), OE # 40100-S9A-E01, 40100-SCA-A01, 40100S9AE01, 40100SCA regular for Honda |

Shear Bolt Torque Limiters (SB) For PTO Shaft |

Continual velocity joint CV sequence, Huge angle eighty, PTO drive shaft for agricultural equipment |

|

Front Driveshaft (Prop Shaft), sixty five-9540 normal for Dodge select-up, OEM / ODM |

Pto Shaft Friction Torque Limiters With Conical Spring Washer |

PTO push shaft for agricultural equipment and tractor, L Sequence German (Metric) Lemon form |

|

Entrance Driveshaft (Prop Shaft), OE # 37110-6A250 common for Toyota Land Cruiser, OEM / ODM |

Pto Shaft With Wide Angle Joint |

Tractor gearboxes for PTO drive shaft, agricultural devices 540 rpm input |

|

Entrance Driveshaft (Prop Shaft), OE # 37110-60450 normal for Toyota Land Cruiser, OEM / ODM |

Outer Yoke With Press-pin For Pto Shaft |

Tractor gearbox for PTO drive shaft, agricultural equipment 540 rpm, one:one.92 ratio |

|

Front Driveshaft (Prop Shaft), 65-9303 common for Ford F250 F350 Super Obligation Pickup, OEM / ODM |

PTO Drive Shaft |

Tractor gearbox for PTO generate shaft, agricultural equipment 540 rpm, three.seventy six:1 ratio |

|

PTO drive shaft for agricultural device and tractor, S Sequence German (Metric) Star shape |

Pto Shaft With Wide Angle Joint EC Laws |

Tractor gearbox for PTO generate shaft, agricultural devices 540 rpm, 3:1 ratio |

|

Friction torque limiter FFVT1-FFVT2 Collection, PTO drive shaft for agricultural equipment |

PTO push shaft High top quality Agricultural PTO Shafts |

PTO push shaft for agricultural equipment and tractor, S Collection American (Domestic) Splined form |

|

Front Driveshaft (Prop Shaft), OE # 37110-6A260 normal for Toyota Land Cruiser |

HZPT push shaft/pto shaft/cardan shaft |

Ratchet torque limiter SA collection, PTO push shaft for agricultural machines |

|

Ratchet torque limiter SA collection, PTO drive shaft for agricultural equipment |

pto shafts/pto shafts portion/cardan shaft |

Friction torque limiter FFVT1-FFVT2 Collection, PTO travel shaft for agricultural machines |

|

PTO generate shaft for agricultural equipment and tractor, S Series American (Domestic) Splined form |

Pto Shaft & Gearbox For Self Propelled Brush Shredder |

PTO push shaft for agricultural machine and tractor, S Collection German (Metric) Star condition |

|

Tractor gearbox for PTO push shaft, agricultural machines 540 rpm, three:one ratio |

Pto Shaft Friction Torque Limiters With Conical Spring Washer (FFT) And Yoke |

Pto Shaft Shear Bolt Torque Limiters (SB) And Yoke |

Content

Substance

Materials accessible

Low carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless steel. Can be tailored regarding customer needs.

Surface area treatment method

Blacking, galvanization, chroming, electrophoresis, shade portray, …

Warmth treatment

Substantial frequency quenching heat treatment method, hardened enamel, carbonizing, nitride, …

Our support

Our services

We Can Offer You:

one.On-time Shipping of a wide range of products

2. Exceptional item options and service

three. Quality ensure

4. Local specialized assistance

five. Fast reaction to customers: Feedbacks in 24 several hours

“Top quality is precedence” At any time-Power folks often attach great value to good quality managing from the really commencing to the stop. Our manufacturing facility has obtained CE, VB, SGS & ISO certificates.

Ever-Electrical power Transmission Team is a team corporation manufacturering all sorts of transmission factors. We have 3 factories and 2 overseas sales firms.

Certifications

Certifications

Our manufacturing unit

Our manufacturing facility

CNC workshop

Tooth profile workshop

Heat treatment workshop

Ginding workshop

Figuring middle

CNC lathe workshop

CNC teeth equipment

Heat therapy equipment

Equipment tooth profile examination devices

3D measurement equipment

Adhere to us

Adhere to us

Where to locate us:

www.hzpt.com/at any time-power/index.html

Fb:

https://www..com/Hangzhou-At any time-Electricity-Co-Ltd-1493406837453589/

Whatsapp / Wechat: +86 130 8398 8828

FAQ

FAQ

Q: Are you investing business or maker ?

A: Our team consists in three factories and two overseas product sales corporations.

Q: Do you offer samples ? is it totally free or further ?

A: Sure, we could provide the sample for free of charge demand but do not shell out the cost of freight.

Q: How prolonged is your delivery time ? What is your conditions of payment ?

A: Usually it is 40-45 days. The time may possibly fluctuate based on the product and the level of customization. For standard goods, the payment is: thirty% T/T in progress ,balance prior to shippment.

Q: What is the precise MOQ or price tag for your solution ?

A: As an OEM company, we can supply and adapt our goods to a wide assortment of wants.As a result, MOQ and cost could drastically vary with measurement, content and even more specs For instance, expensive goods or regular merchandise will normally have a lower MOQ. Make sure you get in touch with us with all appropriate specifics to get the most exact quotation.

If you have one more concern, make sure you truly feel free of charge to speak to us