Product Description

Description:

One of the most widely applied types of flexible couplings is an elastomeric design known as the jaw coupling. This design is characterised by 2 hubs, each having 2 or more thick, stubby protrusions around their perimeters, called jaws, pointing toward the opposing hub. These jaws mesh loosely when the 2 hubs are brought together. Filling the gaps between the jaws are blocks of elastomeric material, usually molded into a single asterisk-shaped element called a “spider”.

Just as coupling designs vary to satisfy different application criteria, so do the spiders in jaw-type couplings. The spider is the key determinant of the torque rating of each jaw coupling. It also can make a significant difference in the coupling’s response to vibration, temperature, chemicals, misalignment, high RPM, space limitations and ease of installation or removal.

Paramters:

Features:

1, Elastic plum-shaped flexible coupling

2,During transmission, it can realize zero backlash torque transmission torque under low torque state

3,The elastic spacer is made of polyurethane, and the torque exceeds the traditional claw coupling by more than 2 times

4,Plum CHINAMFG elastomer can resist oil and electrical insulation, operating temperature: -20ºC~80ºC

5,Excellent elastic effect to absorb vibration, eccentricity and deflection

6,If there are multiple deviations, the allowable value of a single deviation will be reduced

Packing & Delivery:

Application:

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Printing Shops, Construction works , Energy & Mining.

About us:

HangZhou CHINAMFG machinery technology Co., Ltd is an industry transmission solutions manufacuturer and service provider.

We offer 1 stop solution for power transmission products for different factories, such as chemicals, energy, material handling, environmental, extraction, pulp and paper, steel and metal, food and beverage, and construction industries.

We supply: Customised gears, Small gearmotors, Industrial gearboxes, Motors, Brand product sourcing.

Our industrial Gear, Gearbox, gearmotor and motor are sold to more than 30 countries. High quality, good price, in time response and sincere service are our value and promises. We aim at making happy cooperation with our customers, bring them reliable and comfortable service.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do you install and align a flexible coupling properly to ensure optimal performance?

Proper installation and alignment of a flexible coupling are essential to ensure its optimal performance and longevity. Incorrect installation can lead to premature wear, increased vibrations, and potential equipment failure. Below are the steps to install and align a flexible coupling properly:

1. Pre-Installation Inspection:

Before installation, inspect the flexible coupling and its components for any visible damage or defects. Check that the coupling’s size and specifications match the application requirements. Ensure that the shafts and equipment connected to the coupling are clean and free from debris.

2. Shaft Preparation:

Prepare the shafts by removing any oil, grease, or contaminants from the surfaces that will come into contact with the coupling. Ensure that the shaft ends are smooth and free from burrs that could affect the fit of the coupling.

3. Coupling Hub Installation:

Slide the coupling hubs onto the shafts, ensuring they are positioned securely and evenly on each shaft. Use a lubricant recommended by the manufacturer to facilitate the installation and ensure a proper fit.

4. Alignment:

Proper alignment is critical for the performance and longevity of the flexible coupling. Align the shafts by checking both angular and parallel misalignment. Utilize precision alignment tools, such as dial indicators or laser alignment systems, to achieve accurate alignment. Follow the manufacturer’s alignment specifications and tolerance limits.

5. Tightening Fasteners:

Once the shafts are properly aligned, tighten the coupling’s fasteners to the manufacturer’s recommended torque values. Gradually tighten the fasteners in a cross pattern to ensure even distribution of the load on the coupling hubs. Avoid over-tightening, as it may cause distortion or damage to the coupling.

6. Run-Out Check:

After installation, perform a run-out check to verify that the coupling’s rotating components are balanced and aligned. Excessive run-out can lead to vibrations and reduce the coupling’s performance. If significant run-out is detected, recheck the alignment and address any issues that may be causing it.

7. Lubrication:

Ensure that the flexible coupling is adequately lubricated, following the manufacturer’s recommendations. Proper lubrication reduces friction and wear, enhancing the coupling’s efficiency and reliability.

8. Periodic Inspection and Maintenance:

Regularly inspect the flexible coupling for signs of wear, misalignment, or damage. Address any issues promptly to prevent further problems. Depending on the coupling type and application, scheduled maintenance may include re-greasing, re-alignment, or replacing worn components.

Summary:

Proper installation and alignment are crucial for ensuring the optimal performance and longevity of a flexible coupling. Following the manufacturer’s guidelines, inspecting the components, achieving accurate alignment, and using the appropriate lubrication are key steps in the installation process. Regular inspection and maintenance help to identify and address potential issues, ensuring the coupling continues to operate smoothly and efficiently in the mechanical system.

How does a flexible coupling handle misalignment in large rotating equipment?

Flexible couplings are designed to accommodate various types of misalignment in large rotating equipment, ensuring smooth and efficient power transmission while minimizing stress on connected components. Here’s how flexible couplings handle different types of misalignment:

- Angular Misalignment: Angular misalignment occurs when the axes of the two connected shafts are not collinear and form an angle. Flexible couplings can handle angular misalignment by allowing the coupling elements to flex and move slightly, thus accommodating the angle between the shafts. The flexible elements, often made of elastomeric materials or metallic membranes, can bend and twist to compensate for angular misalignment, ensuring that the coupling remains engaged and transfers torque effectively.

- Parallel Misalignment: Parallel misalignment, also known as offset misalignment, happens when the two shafts are not perfectly aligned along their axes, resulting in a lateral shift. Flexible couplings can handle parallel misalignment through their ability to move radially, allowing the flexible elements to adjust and take up the offset. This capability prevents excessive side loads on the shafts and bearings, reducing wear and increasing the lifespan of the equipment.

- Axial Misalignment: Axial misalignment occurs when there is a linear displacement of one shaft relative to the other, either toward or away from the other shaft. Some flexible couplings, such as certain types of flexible disc couplings, can accommodate a limited amount of axial misalignment. However, for large axial movement, other types of couplings or special designs may be required.

The flexibility of the coupling elements allows them to act as a buffer between the shafts, dampening shocks, vibrations, and torsional forces caused by misalignment or other dynamic loads. This helps protect the connected equipment from damage and enhances the overall performance and reliability of the rotating system.

In large rotating equipment, where misalignment is more common due to thermal expansion, foundation settling, or other factors, flexible couplings play a critical role in maintaining smooth operation and reducing stress on the machinery. However, it is essential to choose the appropriate type of flexible coupling based on the specific requirements of the application and to regularly inspect and maintain the coupling to ensure optimal performance and longevity.

What role does a flexible coupling play in reducing downtime and maintenance costs?

A flexible coupling plays a significant role in reducing downtime and maintenance costs in industrial machinery and rotating equipment. Here are the key ways in which flexible couplings contribute to these benefits:

- Misalignment Compensation: One of the primary functions of a flexible coupling is to accommodate misalignment between two connected shafts. Misalignment can occur due to various factors such as thermal expansion, foundation settling, or manufacturing tolerances. By allowing for misalignment, flexible couplings reduce the transmission of harmful forces and stresses to connected components, minimizing wear and preventing premature failures that could lead to costly downtime and repairs.

- Vibration Damping: Flexible couplings have inherent damping properties due to the elastomeric or flexible elements they incorporate. These elements absorb and dissipate vibration and shock loads that may arise from the operation of rotating machinery. By dampening vibrations, flexible couplings protect the connected equipment from excessive wear and fatigue, extending their service life and reducing the need for frequent maintenance or replacement.

- Shock Load Absorption: In applications where sudden loads or shocks are common, such as in heavy machinery or high-speed equipment, flexible couplings act as shock absorbers. They can absorb and dissipate the impact energy, preventing damage to the machinery and minimizing downtime caused by unexpected failures or breakdowns.

- Easy Installation and Alignment: Flexible couplings are designed for ease of installation and alignment. Unlike rigid couplings that require precise shaft alignment, flexible couplings can tolerate some degree of misalignment during installation. This feature simplifies the setup process, reduces installation time, and lowers the risk of misalignment-related issues, ultimately minimizing downtime during initial installation or replacement of couplings.

- Reduced Maintenance Frequency: The ability of flexible couplings to handle misalignment and dampen vibrations results in reduced wear on bearings, seals, and other connected components. Consequently, the frequency of maintenance intervals can be extended, reducing the need for frequent inspections and component replacements. This directly translates to lower maintenance costs and less downtime for maintenance tasks.

- Equipment Protection: By reducing the transmission of shock loads and vibrations, flexible couplings act as protective barriers for connected equipment. They help prevent catastrophic failures and subsequent damage to expensive machinery, avoiding unplanned shutdowns and costly repairs.

Overall, flexible couplings are critical components that improve the reliability and longevity of rotating equipment. Their ability to handle misalignment, dampen vibrations, and protect against shock loads contributes to reduced downtime, lower maintenance costs, and increased productivity in industrial applications.

editor by CX 2024-02-09

Custom China fine blanking steel stamping parts sewing machine parts – Supplier Manufacturer wholesaler Factory

For a lot more data.: Cellular/Whatpp: +8613083988828

The good quality of goods is for us and for our clients of higher importance. This is why we use European created parts in our items. We also complete consistent handle of incoming components and the manage of finished items. In our business we function according to ISO 9001.We “EPG” are a leading manufacturer of a commendable and large good quality assortment of agri-machine elements, Agriculture Gearbox, Thresher Device Head. Established in the year 1997, we are a Sole Proprietorship company that is located at HangZhou China and actively dedicated towards manufacturing the ideal course merchandise in various technical specs and with assured top quality. Under the supervision of our mentor “Alan Schen”, we have been able to attain the various requests and calls for of our consumers.EPG is 1 of the largest makers in China. We have superior equipment for production and new technology screening capability . Via adopting new technology from British, German, U.S.A, our products are very best sellers all above European, The united states, and Southeast Asia.EPG major generation is of farming fifteen-five hundred horsepower tractor supporting equipment, mechanical cultivation, harvesting machinery and equipment.

Overview

Quick Information

- Relevant Industries:

-

Producing Plant

- Brand name Title:

-

OEM

- OEM Support:

-

Assist

- Tolerance:

-

.01-.05mm or Custom-made

- Certification:

-

ISO9001, SGS

- Area Treatment:

-

Sandblasting,Sprucing,Anodize, Zinc,Nickel,Chrome,Plating, and so forth.

- Software:

-

Car,Health-related Equipments,Electric Appliance,Hardware,and so on.

- Dimension:

-

As Customers’ Ask for

- Products:

-

Milling/Lathe/Drilling/4/3 Axis CNC Machining Center

- Drawing Format:

-

Pro/E, Automobile CAD, Solid Functions,IGS,UG, CAD/CAM/CAE

Provide Capacity

- Source Ability:

- ten thousand Piece/Items for each Thirty day period

Packaging & Supply

- Port

- nb

-

Guide Time

: -

Quantity(Items) 1 – 500 >500 Est. Time(times) 30 To be negotiated

Online Customization

Personalized good blanking metal stamping parts sewing device components

Merchandise Description

| Product Type | CNC turning, milling, drilling, grinding, wire EDM chopping and so forth. |

| Our Companies | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Creating,etc |

| Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Wooden,Silicone,Rubber,Or as for each the customers’ needs |

| Surface Remedy |

Anodizing,Sandblasting,Portray,Powder coating,Plating,Silk Printing,Brushing,Sprucing,Laser Engraving |

| Dimension | As customers’ request |

| Service Undertaking | To supply manufacturing style, production and complex services, mould development and processing, and so on |

| Drawing Structure: | PRO/E, Auto CAD, Solid Functions,IGS,UG, CAD/CAM/CAE |

| Testing Device | Digital Peak Gauge, caliper, Coordinate measuring machine, projection device, roughness tester, hardness tester and so on |

| Industry utilized | Machinery hefty obligation tools digital system Car spare components optical telecommunication |

| Packing | Eco-welcoming pp bag / EPE Foam /Carton containers or wood boxes As customer’s certain requirements |

| Trial sample time | 7-10 times soon after affirmation |

| Delivery time | 7-thirty times after receive the pre-payments |

| Payment Terms | T/T,Western Union,Paypal |

OEM Provider

OEM Components

Surface area Remedy

Manufacturing Method

Why Us

EPG – one particular of the most significant transmission factory in China, main items: worm geared motors, agricultrual gearbox, planetary equipment travel, helical,screw, beve gears and spare elements and agricultural elements manunfacuter in China /For much more info.: Cell/Whatpp: +8613083988828

High-precision China customized CNC machine tool for grinding metal stainless steel and plastic gear racks and pinion – Supplier Manufacturer wholesaler Factory

For a lot more information.: Mobile/Whatpp: +8613083988828

we provide a single-stop remedy for the obtain of mechanical energy transmission and pto shaft, agricultural gearboxes merchandise in China. EPG is specialized in style, manufacturer and revenue of agricultural equipment and farm implements, which has an unbiased import and export rights.

Overview

Swift Specifics

- Applicable Industries:

-

Production Plant

- Area of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

White or as ask for

- Module:

-

.4-eight

- Teeth Type:

-

Spur enamel or Helical tooth

- Provider:

-

Reply in twelve hours at any time

Source Potential

- Supply Capacity:

- 5000 Piece/Items for each Thirty day period

Packaging & Supply

- Packaging Specifics

- carton box or non-fumigation Picket scenario

- Port

- Ningbo, Shanghai or as ask for

-

Direct Time

: -

Amount(Bags) one – two hundred 201 – five hundred 501 – 2000 >2000 Est. Time(days) 25 thirty 45 To be negotiated

On the web Customization

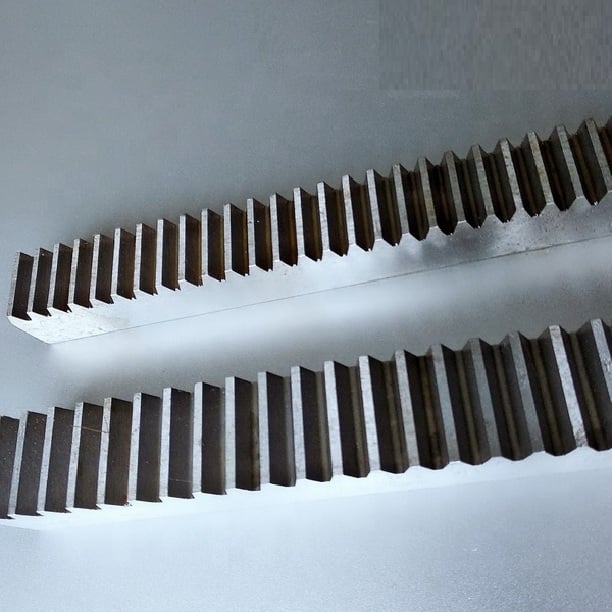

High top quality helical Spur POM Plastic equipment rack

Product description

Simply click below for far more special discounts!

Our spur and helical gear racks are welcomed by several consumers for its stable large good quality and aggressive price.

The producing character of JH gear racks.

1. Gear rack duration: the longest is 4000mm without joint. It can be jointed to any duration.

two. Material: steel C45, stainless metal, substantial power metal, copper, aluminium, nylon, plastic, POM and so on

3. Module: .three-eight (pitch from .942-25.12mm, DP three.a hundred seventy five-85)

four. Quality: steady and higher: accrued tolerance .1mm per 1000mm for typical good quality

Accumulated tolerance .02mm for each 1000mm for four sides ground.

Rates for above top quality are really competitive for us.

The quality character of JH gear racks:

1. Stable transmission and minimal sound

two. Effectively steer clear of typical tolerance based on higher precision

three. The surfaces can be floor to grade seven high quality, and enamel can be ground to quality six good quality

4. The mounting holes can be made as request

five. The price is competitive even the quality is large.

| Facilities |

Machining center CNC gear hobbing machine CNC equipment shaper CNC equipment grinding equipment CNC turning machine CNC milling machine. Y58200 CNC large equipment rack shaper, Y58125A gear rack shaper, England equipment rack shaper and Russia equipment rack shaper, Gleason machine. |

| Material |

Far more: PA6, PA66, POM, Abs and many others. |

| Teeth kind |

Spur teeth equipment rack Helical enamel gear rack Round equipment rack Tube equipment rack Curved gear rack. |

Our Companies

one. Shipping and delivery time: 15-25 days for little order

30-forty five days for massive purchase. (Never delayed until now)

Can be reviewed for far more urgent purchase.

2. Reaction time: usually in 1 hour and in 12 hrs even in our holidays.

three. Process feedback: Photos or vedios will be sent for 2-three occasions to tell you the producing scenario.

four. Check report: The take a look at report can be presented as ask for.

5. Trade phrases: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP and many others.

Business Data

FAQ

Q: Manufacturer?

A: Of course. Given that 2004 only target on creating substantial good quality gears and racks.

Q: Reaction time?

A: Reply quite shortly, and reply in 12 hours at any time.

Our technicians are usually jointly with salesmen, so your any concerns can be replied really before long.

Q: Price?

A: Drawings are much more appriated for quotation. Or, you should inform us your ask for, we will make drawings for your examine.

Q: Supply time?

A: 15-twenty five times for small order (<200 pcs), 30-45 days for large order.

Orders in no way be delayed, the merchandise will be sent on time as arrangement.

Q: Good quality?

A: Center and high high quality is a lot more aggressive.

Sizzling relevant items

Contact us

EPG – one particular of the largest transmission manufacturing facility in China, major merchandise: worm geared motors, agricultrual gearbox, planetary gear generate, helical,screw, beve gears and spare components and agricultural elements manunfacuter in ChinaFor far more info.: Mobile/Whatpp: +8613083988828