We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 diverse branches. For much more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Item Data

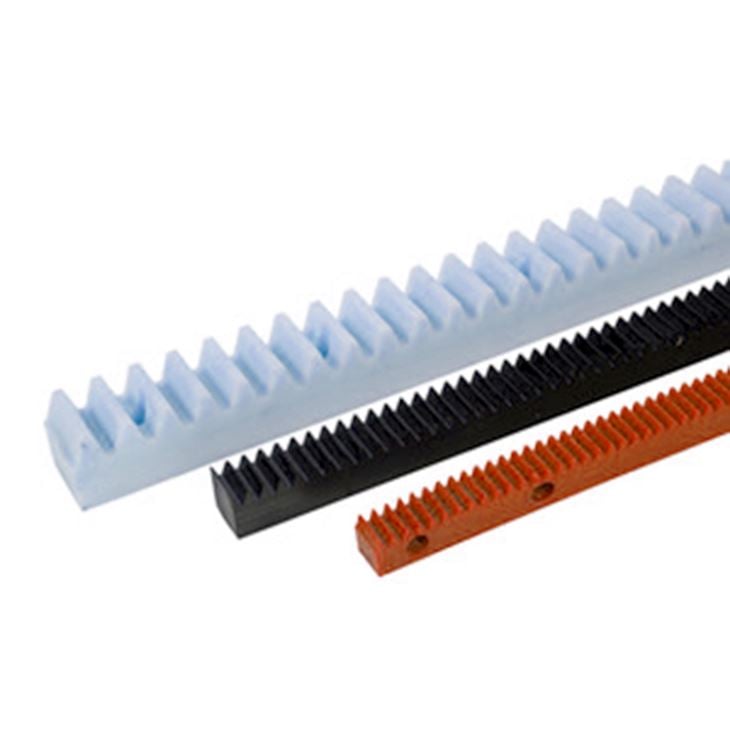

Equipment transmission refers to the device that transmits motion and electrical power from the equipment pair. It is the mo EPT broadly employed mechanical transmission method in present day equipment. Its transmission is a lot more exact, large efficiency, compact construction, reputable procedure and lengthy support lifestyle.

Our gears can be heat taken care of, hardened, oil immersed in accordance to customer wants.

The gear is commonly employed in sector, automobile, electricity instruments, motor, bicycle, electrombile.

|

|

We can make customers’ satisfactory products in accordance to the samples or drawings provided by buyers. For the completion of a solution, we also require to know his content, heat remedy requirements and area treatment specifications. We are a manufacturing unit with 40 several years of production experience, welcome to check with.

Our company focus in making all types of inside and external equipment, higher precision spline shaft and equipment shaft. We are seeking forward to the cooperation with you, and we imagine that we will be your excellent decision.

FAQ

1)Are you investing company or manufacturer?

We are manufacturing facility.

2)How can I customize my merchandise?

Attach your drawing with information(floor treatment method,content,quantity and particular needs and many others.)

three)How lengthy can I get the quotation?

We will give you the quotation inside 48 several hours(contemplating the time distinction)

four)How long will you produce the components?

Generally it is 5-10 days if the goods are in stock. Or it is fifteen-25 days if the merchandise are not in inventory, it’s according to quantity.

five)Do you supply samples? Is it totally free or additional?

Indeed, we could offer you the sample, the samples and shipping fees want to be borne by the client.

6)What is your terms of payment?

Payment≤1000 USD, a hundred% in progress. Payment≥1000 USD, thirty% T/T in advance, harmony ahead of shipment. If you have any concerns, you should will not hesitate to contact us.

seven)What if the items we received are not very good?

Contact us without hesitation, our particular following-income provider will just take the duty.

The use of authentic products manufacturer’s (OEM) part quantities or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating solution use and compatibility. Our firm and the listed alternative parts contained herein are not sponsored, accepted, or made by the OEM.