Product Description

Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling

Product Description

Main products

Coupling refers to a device that connects 2 shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions. Sometimes it is also used as a safety device to prevent the connected parts from bearing excessive load, which plays the role of overload protection.

Couplings can be divided into rigid couplings and flexible couplings.

Rigid couplings do not have buffering property and the ability to compensate the relative displacement of 2 axes. It is required that the 2 axes be strictly aligned. However, such couplings are simple in structure, low in manufacturing cost, convenient in assembly and disassembly, and maintenance, which can ensure that the 2 axes are relatively neutral, have large transmission torque, and are widely used. Commonly used are flange coupling, sleeve coupling and jacket coupling.

Flexible coupling can also be divided into flexible coupling without elastic element and flexible coupling with elastic element. The former type only has the ability to compensate the relative displacement of 2 axes, but cannot cushion and reduce vibration. Common types include slider coupling, gear coupling, universal coupling and chain coupling; The latter type contains elastic elements. In addition to the ability to compensate the relative displacement of 2 axes, it also has the functions of buffering and vibration reduction. However, due to the strength of elastic elements, the transmitted torque is generally inferior to that of flexible couplings without elastic elements. Common types include elastic sleeve pin couplings, elastic pin couplings, quincunx couplings, tire type couplings, serpentine spring couplings, spring couplings, etc

Coupling performance

1) Mobility. The movability of the coupling refers to the ability to compensate the relative displacement of 2 rotating components. Factors such as manufacturing and installation errors between connected components, temperature changes during operation and deformation under load all put CHINAMFG requirements for mobility. The movable performance compensates or alleviates the additional load between shafts, bearings, couplings and other components caused by the relative displacement between rotating components.

(2) Buffering. For the occasions where the load is often started or the working load changes, the coupling shall be equipped with elastic elements that play the role of cushioning and vibration reduction to protect the prime mover and the working machine from little or no damage.

(3) Safe, reliable, with sufficient strength and service life.

(4) Simple structure, easy to assemble, disassemble and maintain.

How to select the appropriate coupling type

The following items should be considered when selecting the coupling type.

1. The size and nature of the required transmission torque, the requirements for buffering and damping functions, and whether resonance may occur.

2. The relative displacement of the axes of the 2 shafts is caused by manufacturing and assembly errors, shaft load and thermal expansion deformation, and relative movement between components.

3. Permissible overall dimensions and installation methods, and necessary operating space for assembly, adjustment and maintenance. For large couplings, they should be able to be disassembled without axial movement of the shaft.

In addition, the working environment, service life, lubrication, sealing, economy and other conditions should also be considered, and a suitable coupling type should be selected by referring to the characteristics of various couplings.

If you cannot determine the type, you can contact our professional engineer

Related products

Company Profile

Our Equipments

Main production equipment:

Large lathe, surface grinder, milling machine, gear shaper, spline milling machine, horizontal broaching machine, gear hobbing machine, shaper, slotting machine, bench drilling machine, radial drilling machine, boring machine, band sawing machine, horizontal lathe, end milling machine, crankshaft grinder, CNC milling machine, casting equipment, etc.

Inspection equipment:

Dynamic balance tester, high-speed intelligent carbon and sulfur analyzer, Blochon optical hardness tester, Leeb hardness tester, magnetic yoke flaw detector, special detection, modular fixture (self-made), etc.

Machining equipments

Heat equipment

Our Factory

Application – Photos from our partner customers

Company Profile

Our leading products are mechanical transmission basic parts – couplings, mainly including universal couplings, drum gear couplings, elastic couplings and other 3 categories of more than 30 series of varieties. It is widely used in metallurgical steel rolling, wind power, hydropower, mining, engineering machinery, petrochemical, lifting, paper making, rubber, rail transit, shipbuilding and marine engineering and other industries.

Our factory takes the basic parts of national standards as the benchmark, has more than 40 years of coupling production experience, takes “scientific management, pioneering and innovation, ensuring quality and customer satisfaction” as the quality policy, and aims to continuously provide users with satisfactory products and services. The production is guided by reasonable process, and the ISO9001:2015 quality management system standard is strictly implemented. We adhere to the principle of continuous improvement and innovation of coupling products. In recent years, it has successfully developed 10 national patent products such as SWF cross shaft universal coupling, among which the double cross shaft universal joint has won the national invention patent, SWF cross shaft universal coupling has won the new product award of China’s general mechanical parts coupling industry and the ZHangZhoug Province new product science and technology project.

Our factory has strong technical force, excellent process equipment, complete professional production equipment, perfect detection means, excellent after-sales service, various products and complete specifications. At the same time, we can provide the design and manufacturing of special non-standard products according to the needs of users. Our products sell well at home and abroad, and are trusted by the majority of users. We sincerely welcome friends from all walks of life at home and abroad to visit and negotiate for common development.p

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can flexible couplings be used in servo motor and stepper motor applications?

Yes, flexible couplings are commonly used in both servo motor and stepper motor applications. They play a crucial role in connecting the motor shaft to the driven load while compensating for misalignments and providing other essential benefits:

- Servo Motor Applications: Servo motors require precise motion control and high responsiveness. Flexible couplings are well-suited for servo motor applications because they offer the following advantages:

- Misalignment Compensation: Servo motors are sensitive to misalignments, which can lead to decreased performance and increased wear. Flexible couplings can accommodate angular, parallel, and axial misalignments, ensuring that the motor and driven load remain properly aligned during operation.

- Vibration Damping: Flexible couplings help reduce vibrations, which is crucial for servo motor applications that require smooth and precise motion. By absorbing and dissipating vibrations, flexible couplings contribute to the overall stability and accuracy of the system.

- Backlash Minimization: Some flexible couplings have minimal to no backlash, making them suitable for high-precision servo motor applications where any play or clearance between components could affect performance.

- High Torque Capacity: Servo motors often require high torque transmission capabilities. Flexible couplings are available in various designs and materials, allowing for the selection of couplings with appropriate torque ratings for specific servo motor applications.

- Stepper Motor Applications: Stepper motors are commonly used in open-loop control systems where precise positioning is necessary. Flexible couplings are used in stepper motor applications due to the following reasons:

- Misalignment Tolerance: Stepper motors can experience misalignments, especially in dynamic applications. Flexible couplings can handle misalignments without introducing significant backlash or affecting the stepper motor’s accuracy.

- Cost-Effectiveness: Flexible couplings are often more cost-effective than other types of couplings, making them a practical choice for stepper motor applications, especially in cases where precision requirements are not as stringent as in servo motor systems.

- Shock Load Absorption: Some stepper motor applications involve abrupt starts and stops, leading to shock loads. Flexible couplings can absorb these shocks and protect the motor and driven load from damage.

- Simplicity: Flexible couplings are simple in design and easy to install, making them a popular choice in various stepper motor applications.

Overall, flexible couplings offer valuable benefits in both servo motor and stepper motor applications. They help improve system performance, reduce wear on components, and enhance the overall reliability of the motion control systems they are employed in.

How does a flexible coupling help in torque and rotational speed control?

A flexible coupling plays a crucial role in torque and rotational speed control in rotating machinery. It offers several benefits that contribute to efficient power transmission and help maintain desired operating conditions:

- Torque Transmission: Flexible couplings transmit torque from one shaft to another while accommodating misalignments. They provide a reliable connection that allows the driving shaft to transfer rotational force (torque) to the driven shaft without causing undue stress on the connected components.

- Smooth Power Transmission: Flexible couplings help reduce shocks and vibrations that can occur during startup, shutdown, or sudden load changes. By damping these vibrations, the coupling ensures smooth power transmission and protects the connected equipment from unnecessary wear.

- Rotational Speed Control: In certain applications, especially those involving precision motion control, maintaining consistent rotational speed is critical. Flexible couplings can help by minimizing backlash and torsional wind-up. Backlash refers to the play or gap between the coupling’s components, while torsional wind-up is the twisting deformation that can occur under torque load. Flexible couplings with low backlash and high torsional stiffness contribute to accurate rotational speed control.

- Compensation for Misalignment: Rotating machinery may experience misalignment due to various factors such as thermal expansion, foundation settling, or machining tolerances. Flexible couplings accommodate angular, parallel, and axial misalignments, which helps in maintaining proper alignment between the shafts and reduces unnecessary torque variations.

- Protection from Overloads: Flexible couplings can act as a mechanical fuse by disengaging or slipping when subjected to excessive torque loads. This feature protects the connected components from damage caused by sudden overloads or jamming events.

- Energy Efficiency: Certain types of flexible couplings, such as elastomeric couplings or beam couplings, have low mass and inertia. This characteristic reduces energy losses and contributes to overall system efficiency.

By providing reliable torque transmission, smooth power transfer, rotational speed control, and compensation for misalignment, flexible couplings optimize the performance and longevity of rotating machinery. Additionally, they enhance the safety and efficiency of various industrial processes by protecting equipment from excessive loads and ensuring smooth operation in diverse applications.

What role does a flexible coupling play in reducing downtime and maintenance costs?

A flexible coupling plays a significant role in reducing downtime and maintenance costs in industrial machinery and rotating equipment. Here are the key ways in which flexible couplings contribute to these benefits:

- Misalignment Compensation: One of the primary functions of a flexible coupling is to accommodate misalignment between two connected shafts. Misalignment can occur due to various factors such as thermal expansion, foundation settling, or manufacturing tolerances. By allowing for misalignment, flexible couplings reduce the transmission of harmful forces and stresses to connected components, minimizing wear and preventing premature failures that could lead to costly downtime and repairs.

- Vibration Damping: Flexible couplings have inherent damping properties due to the elastomeric or flexible elements they incorporate. These elements absorb and dissipate vibration and shock loads that may arise from the operation of rotating machinery. By dampening vibrations, flexible couplings protect the connected equipment from excessive wear and fatigue, extending their service life and reducing the need for frequent maintenance or replacement.

- Shock Load Absorption: In applications where sudden loads or shocks are common, such as in heavy machinery or high-speed equipment, flexible couplings act as shock absorbers. They can absorb and dissipate the impact energy, preventing damage to the machinery and minimizing downtime caused by unexpected failures or breakdowns.

- Easy Installation and Alignment: Flexible couplings are designed for ease of installation and alignment. Unlike rigid couplings that require precise shaft alignment, flexible couplings can tolerate some degree of misalignment during installation. This feature simplifies the setup process, reduces installation time, and lowers the risk of misalignment-related issues, ultimately minimizing downtime during initial installation or replacement of couplings.

- Reduced Maintenance Frequency: The ability of flexible couplings to handle misalignment and dampen vibrations results in reduced wear on bearings, seals, and other connected components. Consequently, the frequency of maintenance intervals can be extended, reducing the need for frequent inspections and component replacements. This directly translates to lower maintenance costs and less downtime for maintenance tasks.

- Equipment Protection: By reducing the transmission of shock loads and vibrations, flexible couplings act as protective barriers for connected equipment. They help prevent catastrophic failures and subsequent damage to expensive machinery, avoiding unplanned shutdowns and costly repairs.

Overall, flexible couplings are critical components that improve the reliability and longevity of rotating equipment. Their ability to handle misalignment, dampen vibrations, and protect against shock loads contributes to reduced downtime, lower maintenance costs, and increased productivity in industrial applications.

editor by CX 2024-02-06

china High Quality Price Ratio factory supplier best water pump motor water pump motor

If you are intrigued in any of our items or would like to examine a prospective purchase, you should really feel totally free to speak to us.

Overview

Fast Particulars

- Following Warranty Services:

-

Video technical help

- Regional Support Spot:

-

Egypt

- Showroom Spot:

-

Egypt

- Kind:

-

elements

- After-product sales Support Supplied:

-

Movie specialized assistance

Provide Ability

- Supply Capability:

- 5000 Piece/Pieces for every Thirty day period hydraulic push motor troubleshooting

Packaging & Shipping and delivery

- Packaging Information

- packaged in plywood case or PALLET

- Port

- Ningbo

On the web Customization

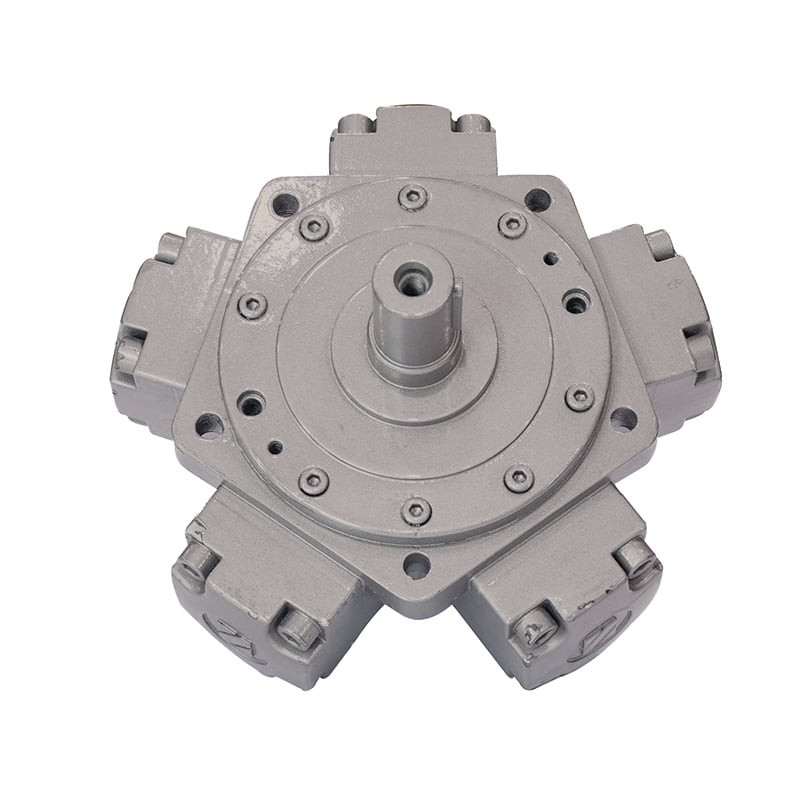

Modern day type exceptional good quality hydraulic pump motor

Item Description

Hydraulic Piston Motor is one kind of lower pace substantial torque radial piston hydraulic motor. It can be widely

applied inpetroleum market, chemical market, mining, delivery, developing machinery, specially for plastics

injection molding machinery, hydraulic winch, transmission ect.

Qualities

Qualities:

one.Reduced sound

2.Substantial staring torque ( mechanical effectiveness enhanced to in excess of .9 ), great balance when lower velocity.

three.Higher volumetic performance

four.Higher mechanical performance

5.Opposite rotating offered

6.Radial and axial load offered

7.Higher kw/kg rati

Technological Knowledge

| Kind | Displacement | Force(Mpa) | Torque(N.m) | Speed range | Max.cont.Electricity | Excess weight | ||

| ml/r | peak. | cont. | Fee | Theoric | r/min | kw | kg | |

| JMDG1-50 | 56 | 32 | 25 | 207 | eight.2 | fifteen-1250 | sixteen | 23 |

| JMDG1-63 | 64 | 32 | 25 | 237 | nine.5 | fifteen-1250 | sixteen | 23 |

| JMDG1-eighty | seventy eight | 32 | twenty five | three hundred | twelve | fifteen-1000 | 16 | 23 |

| JMDG1-a hundred | ninety six | 32 | 25 | 355 | 14 | 15-1000 | 16 | 23 |

| JMDG1-a hundred twenty five | 126 | twenty five | 20 | 380 | 19 | fifteen-one thousand | sixteen | 23 |

| JMDG1-160 | 159 | twenty five | twenty | 472 | 23 | 15-1000 | sixteen | 23 |

| JMDG2-100 | 113 | 32 | 25 | 420 | 18 | 10-1250 | twenty five | 28 |

| JMDG2-a hundred and fifty | 157 | 32 | twenty five | 581 | 25 | ten-one thousand | twenty five | 28 |

| JMDG2-175 | 176 | 25 | twenty | 532 | 27 | 10-1000 | 25 | 28 |

| JMDG2-200 | 201 | twenty five | twenty | 600 | 32 | eight-800 | 25 | 28 |

| JMDG2-250 | 254 | twenty | 16 | 607 | 38 | 8-630 | 25 | 28 |

| JMDG2-280 | 271 | 20 | sixteen | 642 | forty | 8-630 | 25 | 28 |

| JMDG3-two hundred | 199 | 32 | twenty five | 736 | 29 | eight-630 | 37 | 36 |

| JMDG3-250 | 254 | 32 | 25 | 949 | 40 | eight-630 | forty | 36 |

| JMDG3-three hundred | 289 | twenty five | 20 | 864 | 46 | 6-500 | 40 | 36 |

| JMDG3-350 | 351 | twenty five | 20 | 1040 | 55 | six-400 | forty | 36 |

| JMDG3-400 | 397 | 20 | sixteen | 949 | sixty three | six-400 | 40 | 36 |

| JMDG6-400 | 397 | 32 | 25 | 1483 | 63 | five-630 | sixty | 65 |

| JMDG6-450 | 452 | 32 | 25 | 1638 | 72 | five-630 | sixty three | 65 |

| JMDG6-500 | 491 | 25 | twenty | 1463 | seventy eight | five-500 | sixty two | sixty five |

| JMDG6-600 | 594 | 25 | twenty | 1775 | ninety four | 4-500 | sixty five | 65 |

| JMDG6-seven hundred | 683 | 20 | sixteen | 1633 | 103 | 4-400 | sixty five | 65 |

| JMDG6-750 | 754 | twenty | 16 | 1785 | 112 | 4-320 | sixty five | sixty five |

| JMDG8-600 | 617 | 32 | twenty five | 2282 | ninety one | four-five hundred | 70 | seventy one |

| JMDG8-seven hundred | 710 | 32 | twenty five | 2626 | one zero five | 4-four hundred | 70 | seventy one |

| JMDG8-800 | 810 | twenty five | twenty | 2396 | one hundred twenty | four-four hundred | 65 | 71 |

| JMDG8-900 | 889 | twenty five | 20 | 2629 | 131 | three-350 | sixty five | 71 |

| JMDG8-a thousand | a thousand | twenty | 16 | 2366 | 148 | three-300 | 65 | 71 |

| JMDG11-seven-hundred | 714 | 32 | 25 | 2667 | 114 | 4-400 | eighty | ninety |

| JMDG11-800 | 782 | 32 | 25 | 2959 | one hundred twenty | 4-four hundred | 80 | 90 |

| JMDG11-one thousand | 995 | twenty five | twenty | 2974 | 158 | 3-320 | 85 | 90 |

| JMDG11-1100 | 1116 | 25 | twenty | 3336 | 177 | three-320 | 85 | 90 |

| JMDG11-1200 | 1175 | twenty five | 20 | 3512 | 187 | three-320 | eighty five | ninety |

| JMDG11-1300 | 1296 | twenty | 16 | 3080 | 206 | 3-250 | eighty | 90 |

| JMDG16-1400 | 1375 | 32 | 25 | 5138 | 210 | two-400 | a hundred | 160 |

| JMDG16-1600 | 1648 | 32 | twenty five | 6158 | 262 | 2-320 | one hundred ten | one hundred sixty |

| JMDG16-1800 | 1814 | twenty five | twenty | 5433 | 283 | 2-320 | one hundred ten | 160 |

| JMDG16-2000 | 2034 | twenty five | twenty | 6030 | 323 | 2-250 | one hundred ten | one hundred sixty |

| JMDG16-2400 | 2412 | twenty | sixteen | 5763 | 384 | two-250 | 97 | a hundred and sixty |

| JMDG31-2500 | 2550 | 32 | 25 | 9523 | 405 | one-200 | a hundred and fifty | 325 |

| JMDG31-2800 | 2826 | 32 | twenty five | 10559 | 443 | one-200 | a hundred and fifty | 325 |

| JMDG31-3000 | 3050 | twenty five | twenty | 9135 | 485 | 1-200 | 140 | 325 |

| JMDG31-3150 | 3142 | twenty five | twenty | 9392 | 500 | one-two hundred | one hundred forty | 325 |

| JMDG31-3500 | 3419 | twenty five | 20 | 10220 | 544 | one-two hundred | a hundred and forty | 325 |

| JMDG31-4000 | 4170 | 25 | twenty | 12841 | 665 | 1-a hundred and sixty | 130 | 325 |

| JMDG31-4500 | 4522 | 20 | 16 | 10698 | 669 | 1-160 | a hundred thirty | 325 |

| JMDG31-5000 | 5190 | 20 | 16 | 12387 | 825 | one-160 | a hundred thirty | 325 |

| JMDG71-4600 | 4617 | 25 | 20 | 13624 | 735 | one-150 | 145 | 415 |

| JMDG71-5400 | 5459 | 25 | twenty | 16168 | 869 | one-a hundred twenty five | 145 | 415 |

| JMDG71-6300 | 6361 | 20 | sixteen | 16050 | one thousand | one-120 | a hundred forty five | 415 |

| JMDG100-6300 | 6133 | 32 | twenty five | 22916 | 975 | .five-one hundred twenty five | 168 | seven-hundred |

| JMDG100-8000 | 7693 | 32 | twenty five | 28744 | 1223 | .five-125 | 168 | seven hundred |

| JMDG100-10000 | 10688 | 25 | twenty | 31942 | 1699 | .3-a hundred | two hundred | seven-hundred |

| JMDG160-12500 | 13335 | twenty five | twenty | 39433 | 1972 | .three-80 | 220 | a thousand |

| JMDG160-16000 | 16040 | twenty | sixteen | 37948 | 2554 | .three-63 | 220 | 1000 |

Far more Merchandise

Company Details

Packaging & Delivery

| OEM | of course |

| Lead Time | five-20 working days for less than 1500pcs |

| Payment | L/C,T/T |

| thirty% advance payment,the balance paid before shipment | |

| Packing | Motor each have their own carton,the outer packing is a five-layer plywood boxes |

| Shipping and delivery | one)By air or sea or combined transportation |

| 2)Specific:TNT,FEDEX,UPS,DHL |

Our Providers

Get in touch with Us