Product Description

|

Product Name |

High Torque Servo Motor Screw Cross Slider Elastomer Flexible Shaft Couplings |

|

Material |

Aluminum alloy |

|

Surface treatment |

Natural color anode |

|

Customized service |

Support light customization and logo customization |

|

Remarks |

The default engraving brand name and size of the product. If you need not engraving, please contact the customer service for comments |

| Packaging Details | Carton box with anti-static package,carton plus with wooden case. |

| Main Products | Shaft Parts, Timing Belt Pulley, Gears, CNC Machining Parts, Sheet Metal Fabrication |

| Certifications(2) | ISO9001:2015, IPMS |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Farms |

| Supply Ability | 100000 Piece/Pieces per Month |

| Dimension | oem provided |

| Surface finish | anodized |

| Lead Time | 25 days |

| Application | Furniture,cabinet |

| Custom | OEM and ODM services are welcome,we can make cutom LOGO and products according to customer’s requests. |

| Quality control Our | Finished product inspection,Warranty available |

| service | Swiss machining;deburring;lathe/turning;5 axis;micromachining |

| Color |

silver,gold,black,red,bulue,and according to the customer requests. |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the real-world applications of flexible couplings in various industries?

Flexible couplings are widely used in a variety of industries to transmit power and motion between rotating shafts while accommodating misalignments and reducing vibrations. Some of the real-world applications of flexible couplings include:

- Industrial Machinery: Flexible couplings are extensively used in industrial machinery such as pumps, compressors, fans, mixers, and conveyors. They help transmit power from motors to driven equipment, while absorbing misalignments and reducing shock loads and vibrations.

- Automotive: In the automotive industry, flexible couplings are used in various applications, including drive shafts, steering systems, and engine accessories. They help transmit power and motion while allowing for misalignment and reducing torsional vibrations.

- Aerospace: In aircraft and aerospace applications, flexible couplings are used in engine systems, landing gear, and flight control systems. They provide reliable power transmission while accommodating misalignment and reducing vibrations in the demanding aerospace environment.

- Marine: Flexible couplings are used in marine propulsion systems to connect the engine to the propeller shaft. They help transmit power and motion while compensating for shaft misalignment and reducing vibrations in marine vessels.

- Renewable Energy: In wind turbines and solar tracking systems, flexible couplings are used to transfer power and motion between the turbine or solar panel and the generator. They allow for misalignment caused by wind and sun direction changes, ensuring optimal energy conversion.

- Oil and Gas: In the oil and gas industry, flexible couplings are used in pumps, compressors, and drilling equipment. They provide reliable power transmission while accommodating misalignments and reducing vibrations in harsh and demanding oilfield environments.

- Mining and Construction: Flexible couplings are used in heavy-duty mining and construction equipment, including excavators, bulldozers, and loaders. They help transmit power from engines to drive systems while compensating for misalignments and reducing vibrations in rugged and challenging environments.

- Food and Beverage: In food processing and packaging machinery, flexible couplings are used to transmit power and motion while meeting strict hygiene and safety requirements. They help prevent contamination while accommodating shaft misalignments.

- Medical Equipment: Flexible couplings are used in medical devices and equipment, including imaging machines and robotic surgical systems. They help transmit motion and power while reducing vibrations and maintaining precision.

- Textile Industry: In textile manufacturing machines, flexible couplings are used in spinning, weaving, and dyeing processes. They help transmit power efficiently while accommodating misalignments and reducing vibrations during high-speed operation.

These are just a few examples of the diverse applications of flexible couplings in various industries. Their ability to enhance power transmission efficiency, accommodate misalignments, and reduce vibrations makes them a versatile and indispensable component in modern machinery and equipment.

What are the factors influencing the thermal performance of a flexible coupling?

The thermal performance of a flexible coupling can be influenced by several factors, including:

- Material Composition: The material used in the construction of the flexible coupling can impact its thermal performance. Different materials have varying thermal conductivity and heat resistance properties, which can affect how well the coupling dissipates heat generated during operation.

- Operating Speed: The rotational speed of the flexible coupling can influence its thermal behavior. Higher speeds can result in increased friction, leading to more heat generation. Couplings designed for high-speed applications often incorporate features to manage and dissipate heat effectively.

- Power Transmission: The amount of power transmitted through the flexible coupling plays a role in its thermal performance. Higher power levels can lead to increased heat generation, and the coupling must be designed to handle and dissipate this heat without compromising its integrity.

- Environmental Conditions: The ambient temperature and surrounding environment can impact the thermal performance of the flexible coupling. In high-temperature environments, the coupling may need to dissipate heat more efficiently to avoid overheating.

- Lubrication: Proper lubrication is essential for managing friction and heat generation within the coupling. Insufficient or inappropriate lubrication can lead to increased wear and heat buildup.

- Design and Geometry: The design and geometry of the flexible coupling can influence its thermal performance. Some coupling designs incorporate features such as cooling fins, ventilation, or heat sinks to enhance heat dissipation.

- Load Distribution: The distribution of loads across the flexible coupling can affect how heat is generated and dissipated. Proper load distribution helps prevent localized heating and reduces the risk of thermal issues.

Manufacturers consider these factors during the design and selection of flexible couplings to ensure they can handle the thermal demands of specific applications. Proper application and maintenance of the flexible coupling are also essential for optimizing its thermal performance and overall efficiency.

What are the advantages of using flexible couplings in mechanical systems?

Flexible couplings offer several advantages in mechanical systems, making them essential components in various applications. Here are the key advantages of using flexible couplings:

- Misalignment Compensation: One of the primary advantages of flexible couplings is their ability to compensate for shaft misalignment. In mechanical systems, misalignment can occur due to various factors such as installation errors, thermal expansion, or shaft deflection. Flexible couplings can accommodate angular, parallel, and axial misalignment, ensuring smooth power transmission and reducing stress on the connected equipment and shafts.

- Vibration Damping: Flexible couplings act as damping elements, absorbing and dissipating vibrations and shocks generated during operation. This feature helps to reduce noise, protect the equipment from excessive wear, and enhance overall system reliability and performance.

- Torsional Flexibility: Flexible couplings provide torsional flexibility, allowing them to handle slight angular and axial deflections. This capability protects the equipment from sudden torque fluctuations, shock loads, and torque spikes, ensuring smoother operation and preventing damage to the machinery.

- Overload Protection: In case of sudden overloads or torque spikes, flexible couplings can absorb and distribute the excess torque, protecting the connected equipment and drivetrain from damage. This overload protection feature prevents unexpected failures and reduces downtime in critical applications.

- Reduce Wear and Maintenance: By compensating for misalignment and damping vibrations, flexible couplings help reduce wear on the connected equipment, bearings, and seals. This results in extended component life and reduced maintenance requirements, leading to cost savings and improved system reliability.

- Compensation for Thermal Expansion: In systems exposed to temperature variations, flexible couplings can compensate for thermal expansion and contraction, maintaining proper alignment and preventing binding or excessive stress on the equipment during temperature changes.

- Electric Isolation: Some types of flexible couplings, such as disc couplings, offer electrical isolation between shafts. This feature is beneficial in applications where galvanic corrosion or electrical interference between connected components needs to be minimized.

- Space and Weight Savings: Flexible couplings often have compact designs and low inertia, which is advantageous in applications with space constraints and where minimizing weight is crucial for performance and efficiency.

- Cost-Effectiveness: Flexible couplings are generally cost-effective solutions for power transmission and motion control, especially when compared to more complex and expensive coupling types. Their relatively simple design and ease of installation contribute to cost savings.

In summary, flexible couplings play a vital role in mechanical systems by providing misalignment compensation, vibration damping, overload protection, and torsional flexibility. These advantages lead to improved system performance, reduced wear and maintenance, and enhanced equipment reliability, making flexible couplings a preferred choice in various industrial, automotive, marine, and aerospace applications.

editor by CX 2023-12-25

China High Metal Rigidity Flexible Coupling for Stepper Motor Shaft ac coupling

Item Description

Item Description:

Coupling is utilised to link the 2 distinct corporations shaft (driving shaft and pushed shaft) to rotate to common transmission torque of mechanical areas.The overloaded power transmission at higher velocity, some coupling and buffer, vibration and improve the function of shaft technique dynamic functionality.Coupling consists of 2 elements, respectively, and the driving shaft and pushed shaft link.

| Brand | SHAC |

| Uncooked material | Aluminum |

| Inner Diameter | four-60MM |

| Size | twenty five-140MM |

| Product variety | JM1,JM2,JDM,JM-T,JH,TM1/TM2/TM3/TM4,JB,JG,JT |

| Packing | Plastic bag+interior box.In accordance to customer’s request |

| Sample | Totally free sample and catalogue offered |

| Certification | ISO 9001 , ISO 14001 , ISO 14000 |

| Application | CNC devices, medical and foods machinery, fitness equipment, packaging machinery, printing machinery, and other machinery supporting equipment. |

Service:

1,Our Group:

We have skilled and certified staff of advertising and marketing and product sales associates to serve our valued buyers with the greatest goods and unsurpassed service.And have professional engineers crew to evaluation and development the new precision products,and make the OEM custom-made much more effortlessly,knowledgeable QC group to take a look at the merchandise quaity ensure the merchandise quality ahead of shipping out.

2,Our products:

Good quality is the existence .We use only the ideal good quality content to make certain the precision of our

Item.All merchandise we sold out are strictly chosen and analyzed by our QC department.

three,Payment:

We settle for payment through TT (Bank transfer), L/C,Western Union.

4,Delivery strategy:

Including DHL, UPS, TNT, FEDEX,EMS, Airfreight and by Sea,as buyer required.

| To Be Negotiated | 1 Piece (Min. Order) |

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | Different Size as Requirement |

| Torque: | More Than 10n.M |

| Bore Diameter: | 4mm~60mm,Different Size with Different |

| Speed: | Different Size Maximum Rpm Different as Standard |

| Structure: | Flexible |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Brand | SHAC |

| Raw material | Aluminum |

| Inner Diameter | 4-60MM |

| Length | 25-140MM |

| Model number | JM1,JM2,JDM,JM-T,JH,TM1/TM2/TM3/TM4,JB,JG,JT |

| Packing | Plastic bag+inner box.According to customer‘s request |

| Sample | Free sample and catalogue available |

| Certification | ISO 9001 , ISO 14001 , ISO 14000 |

| Application | CNC machines, medical and food machinery, fitness machinery, packaging machinery, printing machinery, and other machinery supporting equipment. |

| To Be Negotiated | 1 Piece (Min. Order) |

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | Different Size as Requirement |

| Torque: | More Than 10n.M |

| Bore Diameter: | 4mm~60mm,Different Size with Different |

| Speed: | Different Size Maximum Rpm Different as Standard |

| Structure: | Flexible |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Brand | SHAC |

| Raw material | Aluminum |

| Inner Diameter | 4-60MM |

| Length | 25-140MM |

| Model number | JM1,JM2,JDM,JM-T,JH,TM1/TM2/TM3/TM4,JB,JG,JT |

| Packing | Plastic bag+inner box.According to customer‘s request |

| Sample | Free sample and catalogue available |

| Certification | ISO 9001 , ISO 14001 , ISO 14000 |

| Application | CNC machines, medical and food machinery, fitness machinery, packaging machinery, printing machinery, and other machinery supporting equipment. |

Programming With Couplings

A coupling is a mechanical device that connects two shafts together and transmits power. Its purpose is to join rotating equipment and allows some degree of end-movement or misalignment. There are many different types of couplings. It’s important to choose the right one for your application.

Mechanical connection between two shafts

There are many ways to achieve mechanical connection between two shafts, including the use of a coupling. One common type is the beam coupling, which is also known as a helical coupling. It is used for transmission of torque between two shafts. This type of connection accommodates axial, parallel and angular misalignments.

The hubs and shafts of a worm gear are connected together by a coupling. This mechanical connection allows one shaft to turn another without causing a mechanical failure. This type of coupling is made from sliding or rubbing parts to transfer torque. However, the coupling is not designed to withstand jerks, so it isn’t suitable for high-speed applications.

The use of a coupling is common in machinery and equipment. It helps transmit power from one drive shaft to the other, while adding mechanical flexibility. It is also useful for reducing the impact and vibration caused by misalignment. It also protects the drive shaft components from wear and tear.

A double-hook coupling can be used to provide a uniform angular velocity at the driven shaft. Another example is a double-jointed coupling. A double-jointed coupling can be used to connect shafts that are not directly intersecting. The double-jointed yoke can be used for the same purpose.

A shaft coupling is a device that maintains a strong mechanical connection between two shafts. It transfers motion from one shaft to another, at all loads and misalignments. Unlike a conventional linkage, a shaft coupling isn’t designed to allow relative motion between the two shafts. Couplings often serve several purposes in a machine, but their primary use is torque and power transmission.

Functions that control the flow of another function

One of the simplest programming constructs is a function that controls the flow of another function. A function can take an argument and return a different value, but it must be ready to return before it can pass that value to another function. To do this, you can use the goto statement and the if statement. Another way to control flow is to use a conditional statement.

Criteria for selecting a coupling

There are several important factors to consider when choosing the right coupling. One of the most important factors is coupling stiffness, which depends on the material used and the shape. The stiffness of a coupling determines its ability to resist elastic deformation. A stiff coupling is desirable for certain types of applications, but it’s undesirable for others. Stiffness can reduce the performance of a system if there’s too much inertia. To avoid this, ensure that the coupling you choose is within the recommended limits.

The size of a coupling is also important. Different coupling types can accommodate different shaft sizes and shapes. Some couplings have special features, such as braking and shear pin protection. When choosing a coupling, you should also consider the type of driven equipment. If you need to connect a high-torque motor, for example, you’ll want to choose a gear coupling. Likewise, a high-speed machine may require a disc coupling.

Another factor to consider when selecting a coupling is the torque rating. Despite its importance, it’s often underestimated. The torque rating is defined as the torque of the coupling divided by its OD. In some cases, torque may fluctuate during a cycle, requiring a coupling with a higher torque rating.

Torsionally flexible couplings are also important to consider. Their design should be able to withstand the torque required during operation, as well as the required speed. The coupling should also have a high degree of torsional stiffness, as well as damping. Furthermore, a damping coupling can reduce the energy wasted through vibration.

The sizing of a coupling is also determined by the torque. Many engineers use torque to select the correct coupling size, but they also take into consideration torsional flexibility and torsional stiffness. For example, a shaft may be able to handle large torque without damaging the coupling, while a disk may be unable to handle large amounts of torque.

Besides torque, another important consideration in coupling selection is the cost. While a coupling may be cheaper, it may be less reliable or easier to maintain. Couplings that are difficult to service may not last as long. They may also require frequent maintenance. If that’s the case, consider purchasing a coupling with a low service factor.

There are many different types of couplings. Some require additional lubrication throughout their lifetime, while others are 100% lubrication-free. An example of a 100% lubrication-free coupling is the RBI flexible coupling from CZPT. This type of coupling can significantly reduce your total cost of ownership.

In addition to the above-mentioned benefits, elastomeric couplings are low-cost and need little maintenance. While they are often cheaper than metallic couplings, they also have excellent shock absorption and vibration dampening properties. However, they are susceptible to high temperatures. Also, they are difficult to balance as an assembly, and have limited overload torque capacity.

editor by czh 2022-11-29

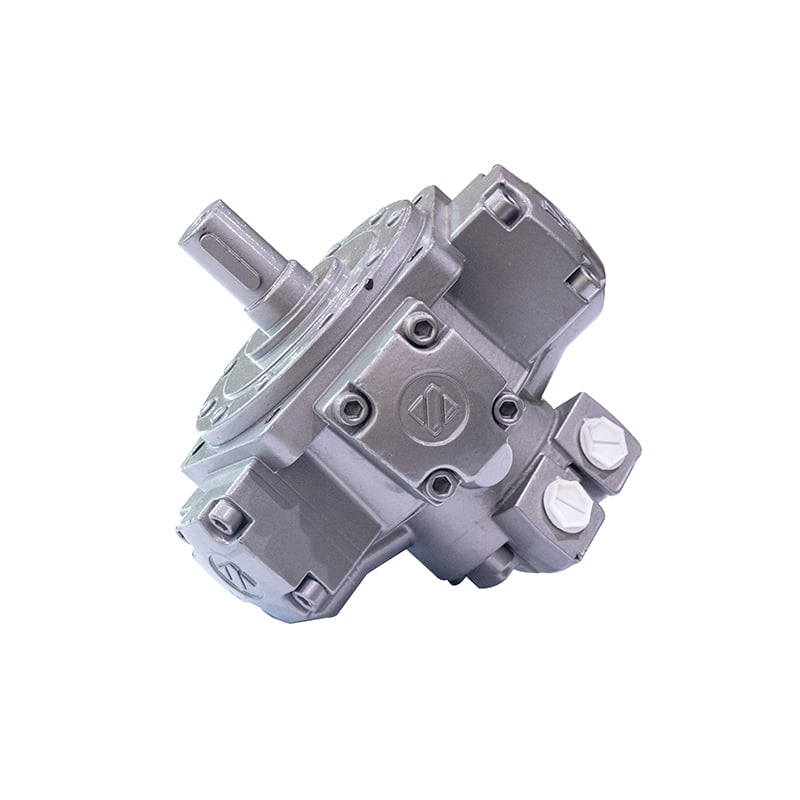

China manufacturer & factory supplier for china in Thessaloniki Greece supplier radial piston pneumatic motorradial piston motor 600ccradial piston motor valve With high quality best price & service

engineering course chains & precision roller chains. Single strand chain, multi-strand chains, double pitch chains, corrosion resistant chains, self-lubricating chains, attachment chains, leaf chains, and specialty chains. we have received the have confidence in of consumers around the world. a specialized provider of a entire range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Swift Information

the demands and needs of our buyers – from standard solutions to consumer-specific styles.

- Situation:

-

New

- Warranty:

-

1.5 several years

- After Warranty Provider:

-

Online video complex support

- Nearby Service Location:

-

Egypt

- Showroom Spot:

-

Egypt

- Type:

-

areas

- Manufacturer Name:

-

OEM

- Location of Origin:Zhejiang, China

- Strain:

-

Hydraulic stress

- Framework:

-

Hydraulic system, 5 Radial Piston Motor

- Certification:

-

CE

- Fat:

-

≤1000kg

- Electrical power:

-

16000-220000

- Right after-sales Support Presented:

-

Online video specialized assistance

Adhering to “Survival by Top quality, Growth by Engineering & Credit rating”, The organization will continuously increase solution functionality to meet up with the escalating customer demands in the arduous style of function.

Offer Potential

- Supply Capacity:

- 500000 Piece/Parts for every 12 months

Packaging & Delivery

- Packaging Information

- packaged in plywood scenario or PALLET

- Port

- NINGBO/SHANGHAI, CHINA

-

Guide Time

: -

Amount(Baggage) 1 – 50 >50 Est. Time(times) 15 To be negotiated

Online Customization

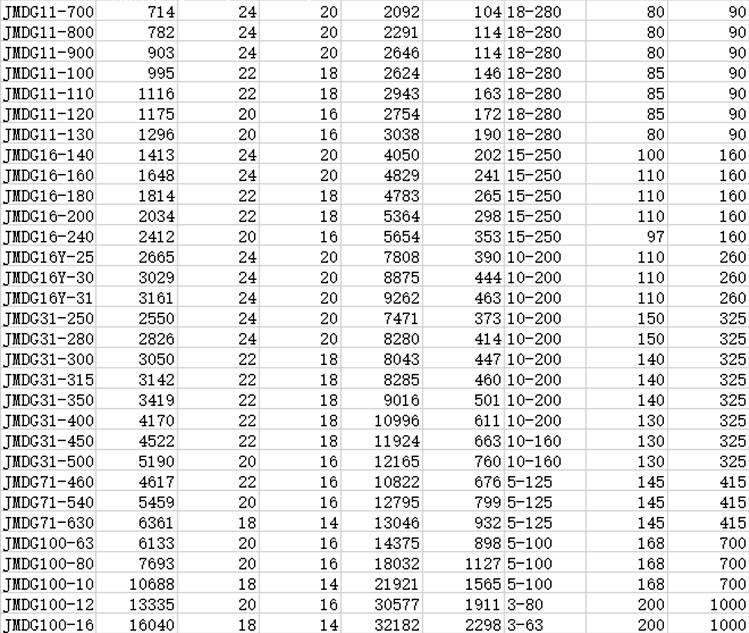

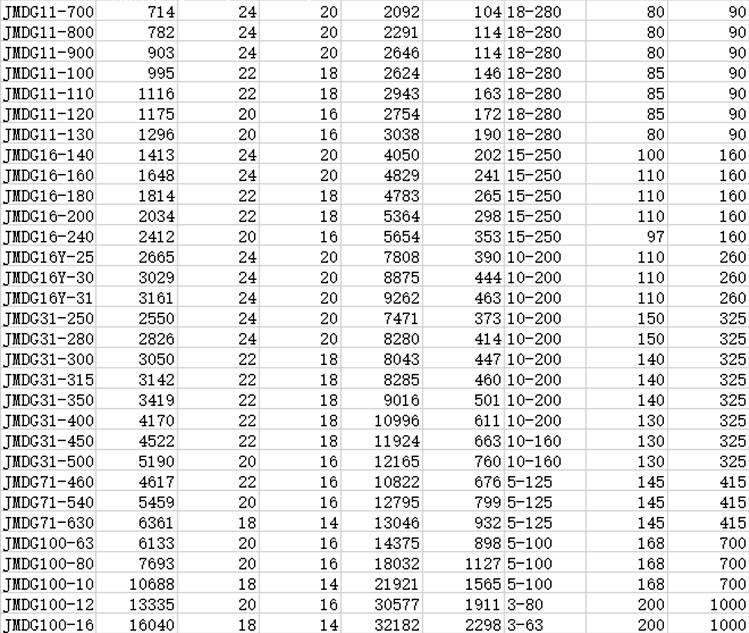

Specialized Data

| Sort | Displacement (ml/r) |

Stress (Mpa) |

Torque(N.m) | Velocity Assortment (r/min) |

Max.cont. Electricity (kw) |

Excess weight (kg) |

||

| (N.m) Rate torque |

N.m/Mpa Theoric Torque |

|||||||

| peak force | cont.stress | |||||||

| JMDG1-50 | fifty four | 24 | 20 | 164 | 8 | 35-500 | six | 23 |

| JMDG1-sixty three | sixty four | 24 | 20 | 188 | nine | 35-five hundred | seven | 23 |

| JMDG1-eighty | seventy eight | 22 | eighteen | 206 | eleven | 35-500 | nine | 23 |

| JMDG1-a hundred | 96 | 22 | 18 | 253 | 14 | 35-500 | 11 | 23 |

| JMDG1-one hundred twenty five | 126 | 22 | 18 | 332 | 18 | 35-five hundred | fifteen | 23 |

| JMDG1-a hundred and sixty | 159 | twenty | 16 | 373 | 23 | 35-500 | 16 | 23 |

| JMDG2-a hundred | 113 | 24 | 20 | 331 | seventeen | thirty-400 | eleven | 28 |

| JMDG2-one hundred fifty | 157 | 24 | 20 | 460 | 23 | thirty-400 | fifteen | 28 |

| JMDG2-a hundred seventy five | 176 | 22 | 18 | 464 | 26 | thirty-four hundred | seventeen | 28 |

| JMDG2-200 | 201 | 22 | 18 | 530 | 29 | thirty-four hundred | 19 | 28 |

| JMDG2-250 | 254 | 20 | sixteen | 595 | 37 | thirty-400 | 21 | 28 |

| JMDG2-280 | 271 | 20 | 16 | 635 | 39 | 30-four hundred | 23 | 28 |

| JMDG3-two hundred | 199 | 22 | eighteen | 525 | 29 | thirty-350 | 25 | 36 |

| JMDG3-250 | 254 | 22 | 18 | 670 | 37 | 30-350 | 32 | 36 |

| JMDG3-300 | 289 | 22 | 18 | 762 | forty two | 30-350 | 32 | 36 |

| JMDG3-350 | 351 | 22 | eighteen | 926 | fifty one | thirty-350 | 32 | 36 |

| JMDG3-400 | 397 | 20 | sixteen | 931 | fifty eight | thirty-350 | 32 | 36 |

| JMDG3-450 | 462 | 20 | sixteen | 1083 | sixty eight | 30-350 | 32 | 36 |

| JMDG6-four hundred | 397 | 22 | eighteen | 1047 | 58 | 25-320 | 46 | 65 |

| JMDG6-450 | 452 | 22 | 18 | 1192 | 66 | twenty five-320 | 53 | sixty five |

| JMDG6-500 | 491 | 22 | eighteen | 1295 | seventy two | twenty five-320 | fifty three | 65 |

| JMDG6-600 | 594 | 22 | eighteen | 1566 | 87 | twenty five-320 | 63 | 65 |

| JMDG6-seven-hundred | 683 | 22 | eighteen | 1801 | one hundred | 25-320 | sixty three | 65 |

| JMDG6-750 | 754 | twenty | sixteen | 1767 | 110 | twenty five-320 | sixty three | 65 |

| JMDG6-800 | 799 | twenty | sixteen | 1873 | 117 | 25-320 | sixty three | 65 |

| JMDG8-600 | 617 | 22 | eighteen | 1627 | Slip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST Types a few distinct kinds of PTO in procedure: a non shear, shear pin and slip clutch — the last currently being the most high-priced. Employ end of non shear (r) and shear sort (l) Non shear: this is a solid yoke to yoke established up and used with the expectation that particular equipment will not encounter any sudden stops. I figure that the finishing mower does not need to have a shear set up as the blades will slip to a degree currently being belt driven and my other mower, the flail mower, is extremely forgiving in its style.90 | 20-280 | eighty | seventy one |

| JMDG8-seven hundred | 710 | 22 | eighteen | 1872 | 104 | 20-280 | eighty | 71 |

| JMDG8-800 | 810 | 22 | 18 | 2136 | 118 | twenty-280 | eighty five | 71 |

| JMDG8-900 | 889 | twenty | sixteen | 2084 | one hundred thirty | twenty-280 | eighty five | seventy one |

| JMDG8-a thousand | 1000 | 20 | 16 | 2344 | 146 | 20-280 | eighty five | seventy one |

| JMDG8Y-seven hundred | 710 | 24 | twenty | 2080 | one zero one | twenty-280 | eighty five | 75 |

| JMDG8Y-800 | 810 | 24 | 20 | 2373 | 116 | 20-280 | eighty five | seventy five |

| JMDG8Y-900 | 889 | 24 | twenty | 2604 | 127 | twenty-280 | eighty five | seventy five |

| JMDG8Y-1000 | 1000 | 24 | twenty | 2930 | 143 | twenty-280 | eighty five | seventy five |

| JMDG8Y-1100 | 1117 | 22 | 18 | 2945 | one hundred sixty | twenty-280 | ninety | seventy five |

| JMDG8Y-1200 | 1178 | 22 | eighteen | 3106 | 168 | twenty-280 | 90 | 75 |

Intermittent operation the permssible values might take place for max. ten% of each minute

Peak load: the permissible values could occur for max.1% of each minute

Low made in China – replacement parts – in Samsun Turkey Speed 60W 15nm Torque DC Gear Motor with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox factory in China with 5 distinct branches. For far more particulars: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

A. Specification of Low Velocity 60W 15Nm Torque DC Equipment Motor:

1. Voltage: 12V/24V/90V

two. Pace: 3.7-933PM

three. Torque: 5.07-200Kgf.cm

4. Output Energy: 60W

five. Gearbox Ratio: one:3 to 1: 750

6. Gearbox Diameter: 90mm

seven. Gearbox Duration: 65mm

8. Motor Length: 143mm

9. Shaft Diameter: 15mm

10. Motor Bodyweight: two.2Kg

11. Gearbox Weight: 1.21-1.45Kg

Observe: The information sheet is only for reference, We can make the motor in accordance to your requirement right after Analysis

B. Business Potential

HangZhou Leison Motor Co. Ltd is a maker and exporter of a variety of of motors with more than 10 a long time expertise.

Our product ranges consist of:

1) DC Brush motor: 6-130mm diameter, .01-1000W output electricity

two) DC Spur Equipment Motor: twelve-110mm diameter, .1-300W output power

three) DC Planeary Gear Motor: ten-82mm diameter, .1-100W output power

four) Brushless DC Motor: 28-110mm, 5-1500W output power

five) Stepper Motor: NEMA 08 to NEMA 43, Can with gearbox and direct screw

6) Servo Motor: 42mm to 130mm diameter, fifty-4000w

7) AC Gear Motor: forty nine to 100mm diameter, 6-one hundred forty output power

1. Manufacturing Line:

two. Tests Tools:

3. Certificates:

4. Buyer Visits:

6. FAQ:

Q: What is actually your principal items?

A:We at the moment create Brushed Dc Motors, Brushed Dc equipment Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors and Ac Motors and many others. You can verify the technical specs for earlier mentioned motors on our website and you can email us to advise required motors for every your specification too.

Q:How to pick a suitable motor?

A:If you have motor photos or drawings to show us, or you have thorough specs like voltage, speed, torque, motor dimension, working method of the motor, needed life time and sounds stage and so forth, you should do not hesitate to let us know, then we can advocate ideal motor for each your reque EPT appropriately.

Q: Do you have custom-made support for your standard motors?

A:Sure, we can personalize per your reque EPT for the voltage, velocity, torque and shaft dimensions/form. If you need extra wires/cables soldered on the terminal or want to insert connectors, or capacitors or EMC we can make it also.

Q:Do you have personal layout service for motors?

A:Indeed, we would like to design motors individually for our buyers, but it could require some mould charge and design and style demand.

Q:Can I have samples for tests 1st?

A:Sure, definitely you can. Soon after verified the necessary motor specs, we will quotation and supply a proforma bill for samples, as soon as we get the payment, we will get a PASS from our account department to continue samples appropriately.

Q:How do you make certain motor top quality?

A:We have our possess inspection methods: for incoming supplies, we have signed sample and drawing to make confident qualified incoming components for manufacturing process, we have tour inspection in the method and ultimate inspection to make confident certified merchandise ahead of shipping and delivery.

Q:What is actually your guide time?

A:Typically speaking, our normal common solution will require twenty five-30days, a bit lengthier for customized goods. But we are quite adaptable on the direct time, it will is dependent on the certain orders

Q:What’s your payment term?

A:For all our new customers, we will need 40% deposite, 60% paid out just before cargo.

Q:When will you reply soon after obtained my inquiries?

A:We will response inside 24 hours as soon as get your inquires.

Q:How can I tru EPT you to make positive my money is secure?

A:We are accredited by the 3rd social gathering SGS and we have exported to more than 85 countries up to June.2017. You can check our reputation with our recent clients in your nation (if our consumers do not thoughts), or you can order by way of alibaba to get trade assurance from alibaba to make sure your cash is risk-free.

Q:What’s the minimum get quantity?

A:Our minimum buy quantity depends on various motor designs, remember to email us to verify. Also, we generally do not acknowledge personalized use motor orders.

Q:What is actually your delivery technique for motors?

A:For samples and packages significantly less than 100kg, we normally sugge EPT categorical shipping For hefty deals, we normally sugge EPT air delivery or sea shipping. But it all relies upon on our customers’ needs.

Q:What certifications do you have?

A:We at present have CE and RO EPT certifications.

Q:Can you deliver me your value list?

A:Because we have hundreds of different items, and value varies for each diverse specs, we are not able to offer a price record. But we can estimate inside 24 hrs as soon as received your inquirues to make sure you can get the value in time.

Q:Can I visit your firm?

A:Of course, welcome to visit our company, but you should enable us know at lea EPT two months in progress to aid us make positive no EPT meetings for the duration of the day you check out us. Many thanks!

Weclome get in touch with with us if have any inquiries about this motor or EPT merchandise!

The use of unique tools manufacturer’s (OEM) part numbers or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating item use and compatibility. Our company and the shown substitution components contained herein are not sponsored, approved, or created by the OEM.

DC made in China – replacement parts – in Patna India Electric Motor 48V 1500W 1500rpm BLDC Motor for Tracked Robot with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox factory in China with 5 distinct branches. For much more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

DC Electric Motor 48V 1500W 1500rpm BLDC Motor for Tracked Robot

PG36M555 Series

voltage: 3VDC 6VDC 9VDC 12VDC 24VDC

Speed selection: 3000-9500rpm

energy: 3.3-13w

Normal applications: Central air-conditioning valve, Amusement gear, Coin

Refund devices, Grill, Oven, Peristaltic pumps, ATM financial institution

Automated system, Robot, Health care tools, Workplace

Equipment, Home appliances, Automatic actuator.

Fat: 320~400g/PCS(approx)

Packing details: CTN size: 32X28XH26cm 40PCS/CTN G. W. 16Kgs

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Company Introduction

The use of first gear manufacturer’s (OEM) element numbers or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating item use and compatibility. Our organization and the outlined substitute elements contained herein are not sponsored, authorized, or produced by the OEM.

Best China manufacturer & factory Y2 in Abeokuta Nigeria Series Three Phase Induction Ac Electric Motor With high quality best price

our products are selling well in the American, European, South American and Asian markets. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Model Number:

-

631-4/0.12KW

- Type:

-

Asynchronous Motor

- Frequency:

-

50HZ

- Phase:

-

three-phase

- Certification:

-

CCC, ce

- AC Voltage:

-

220/380V

Slip clutch: this type uses a slip clutch on the driven end yoke which is comprised of three steel plates in line held together with a series of bolts with springs under the nuts. The idea here is that when you tighten the nuts the pressure is increased onto the centre plate which when set up for the load will allow the shaft to turn and the implement to stall, absorbing the shock load. As mine is rated from 20-40 hp and I’m running a 17 hp I had to make alterations to set it up. Through trial and error I determined that I had to remove half the tension bolts and springs and back off the remainder nuts to minimum in order for the clutch to “slip” prior to stall on the tractor.

- Color:

-

Silverr plastic coating

- Product Name:

-

Y2 Series Ac Motor

We distribute many other items that are not listed above, but are still readily available. Feel free to give us a call or send us an email. We are always ready to help.

Supply Ability

- Supply Ability:

- 15000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Each in carton box,then packed in wooden case.

- Port

- NINGBO/SHANGHAI

Online Customization

The company was certified by ISO9001:2008 Quality Management System.

Y2 Series Three Phase Induction Ac Electric Motor

| Product Name | Y2 Series Three Phase Induction Ac Electric Motor |

| Color | Silverr plastic coating |

| frequency | 50HZ |

1. Can your factory accept OEM or ODM?

Yes,we have OEM & ODM for more than 22 years.

2.Can you offer sample?

Yes,we can offer Free samples for VIP.

3.How about your requirement for MOQ.?

We have very low requirement on Min. Order Quantity.

4.Do your factory offer quality warranty?

Yes,quality warrantee is guaranteed.

5.Do your factory offer trade assurance?

Certainly,we have trade assurance program support.

6.Do your factory accept distribution agent?

Yes, distribution agent is warmly welcomed.

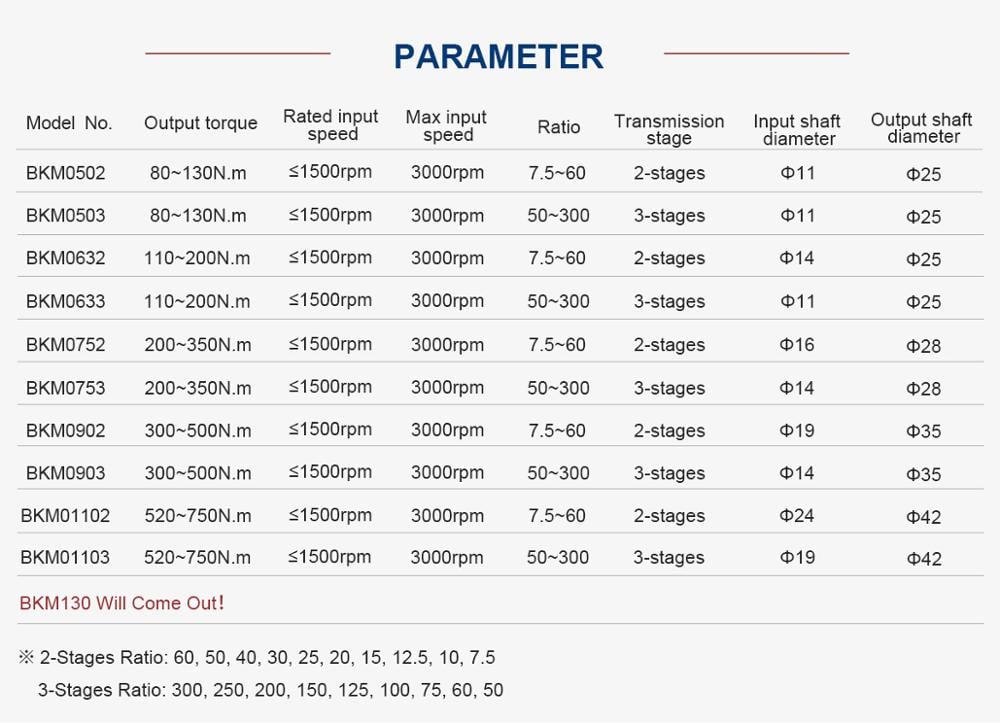

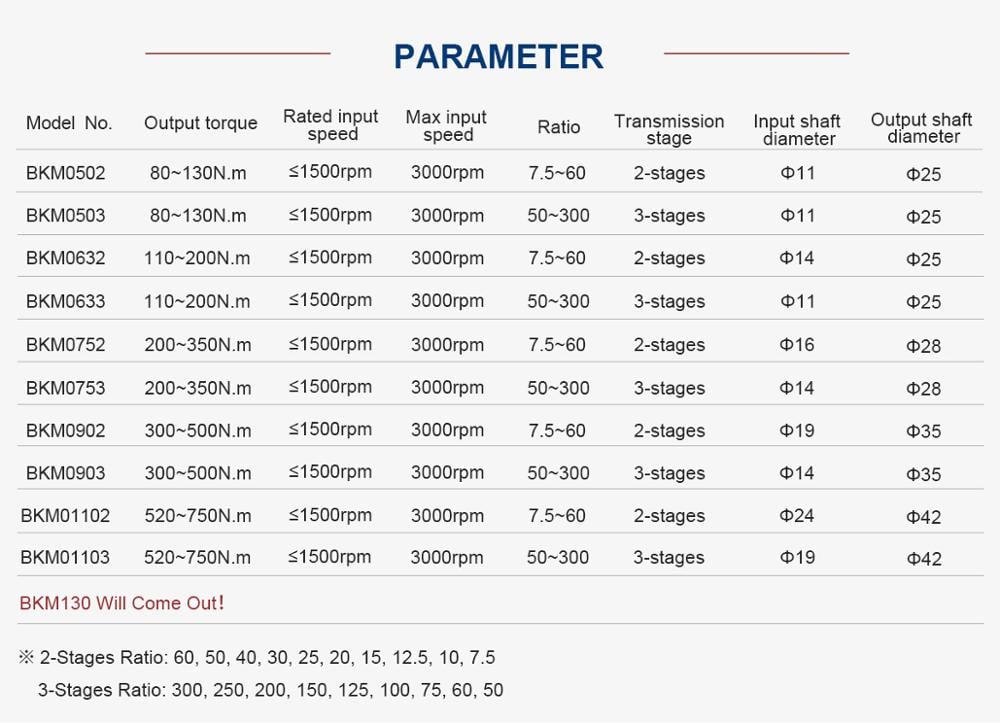

Best China manufacturer & factory china manufacturer BKM1102 hypoid gear motor speed reducer for conveyor belt With high quality best price

Our product range includes all kinds of helical gear, spur gear, bevel gear, gear rack, worm gear, sprockets,chains, bearings, pto shaft, agricultural gearboxes.

Overview

Quick Details

- Applicable Industries:

-

precision machinery

- Gearing Arrangement:

-

Hypoid

- Output Torque:

-

520~750 N.m

- Input Speed:

-

≤1500 rpm

- Output Speed:

-

*

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Product name:

-

hypoid motor reducer for conveyor belt

- Ingress Protection:

-

IP65

- Ratio:

-

7.5~60

- Color:

-

gray /blue/black

- Heat treatment:

-

surface hardening

- Housing Material:

-

Our products is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South America, Thailand, Pakistan, Indonesia, more than 60 countries and regions.

aluminum alloy

Supply Ability

- Supply Ability:

- 200000 Piece/Pieces per Month

Packaging & Delivery

- Port

- Ningbo/Shanghai/ China Port

-

Lead Time

: -

Quantity(Sets) 1 – 1000 >1000 Est. Time(days) 30 To be negotiated

Online Customization

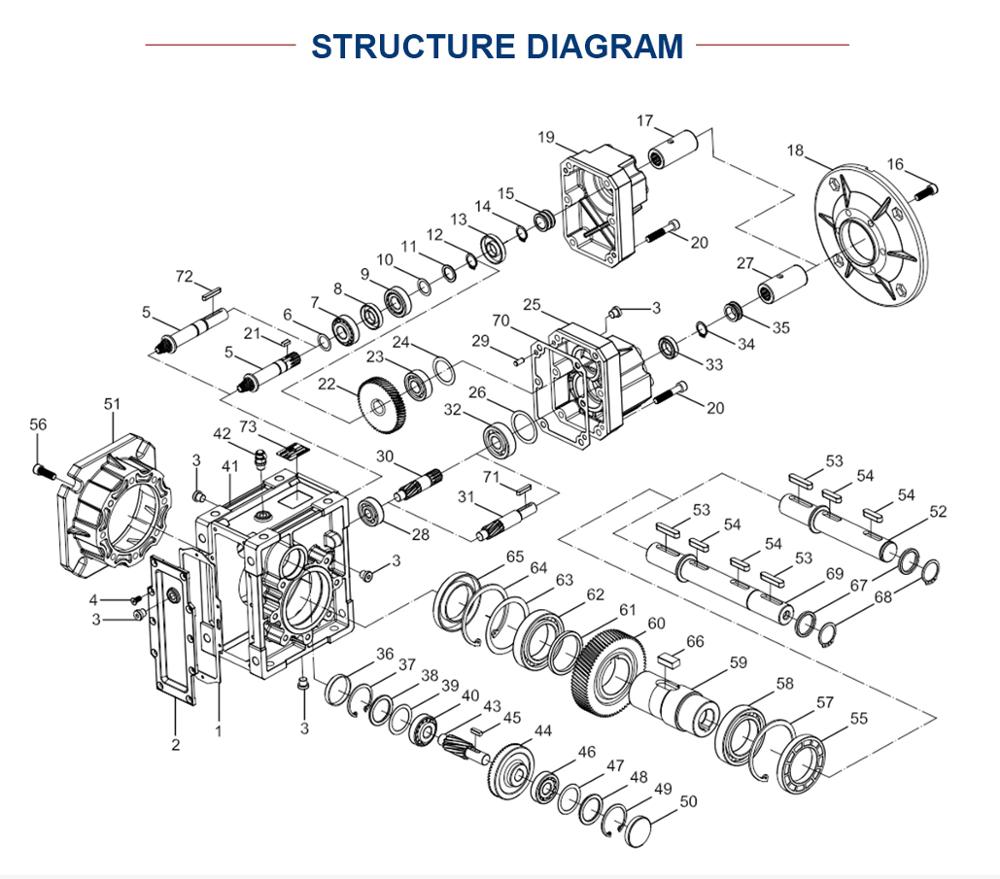

Ever-power Group Co., Ltd. is SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, PARALLEL SWorm Gears A worm gear system consists of a worm and worm wheel positioned as a cross axis and is the most compact type of gear system. Due to the compact design, worm gear reducers are able to be placed in relatively small spaces and provide high-ratio speed reduction. Worm gears are known to run smoothly and quietly, as long as they are properly mounted and lubricated.HAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEPTO Shaft Safety Tips The most common PTO related injuries tend to occur when articles of loose clothing become entangled in the shaft. When operating the PTO, never reach over the shaft for any reason and avoid wearing loose-fitting clothing. Injury can occur quickly, providing the operator little time to react, and in some cases resulting in death.ARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAULIC SYSTEM, VACCUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND SO ON. FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS DRAWINGS.

HangZhou Ever-PowerMechanical & Electrical Co., Ltd. is a professional manufacturer ofgearbox and motors.The factory covers an area of 20,000 square meters, the building area of 30,000 square meters, the total number of staff is more than 200 .We have passed theISO9001:2015international quality management system standard certificate,CCCnational compulsory product certificate andCEcertificate . We have developed advanced management software such asERPto keep pace with international standard.In order to serve customers better the company actively cooperates with colleges and universities to develop new products and improve existing products .

|

Q1. Are you trading company or manufacturer? A. We are manufacturer Located in Taizhou City of East China. Q2. How is guarantee of the quality? With ISO9001:2015,CE,CCC certificated, Our inspectors sampled inspect and record material and semi-finished spare parts. And – 100% inspect finished spare parts before put in storage. – 100% inspect before assembly. – 100% inspect before packaging. Q3. What information shall we give before placing a purchase order? We can supply technical support and the drawing according to your requirement if you contact with me. Q4. What industries are your gearboxes being used? Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry,escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc. Q5. Do you have warranty service? Yes, the gearbox is free warranty within 1 years after delivery. |

||||||

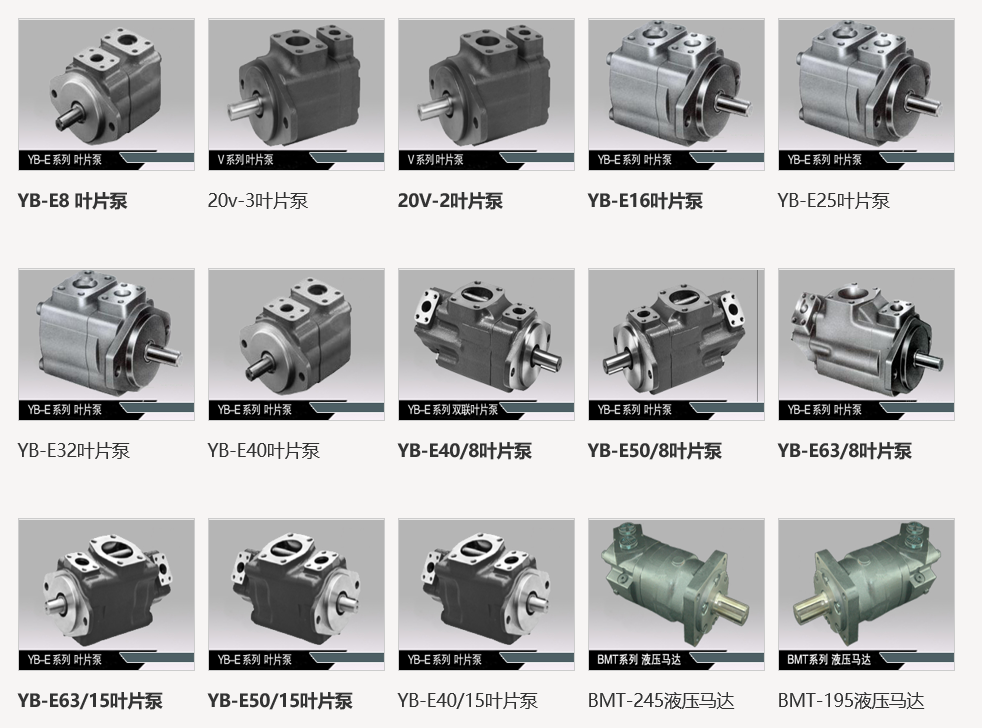

Best China manufacturer & factory china supplier factory exporter Char-Lynn motor 105-1001 105-1002 105-1003 105-1004 105-1005 105-1006 105-1007 105-1060 105-1152 With high quality best price

ensures the stability and consistency of the key function of components.

Overview

Quick Details

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

Egypt

- Showroom Location:

-

Egypt

- Type:

-

parts

- After-sales Service Provided:

-

Video technical support

Supply Ability

- Supply Ability:

- 500000 Piece/Pieces per Year

Packaging & Delivery

- Packaging Details

- Carton or Plywood case or PALLET

- Port

- NINGBO/SHANGHAI, CHINA

Slip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST MODELS three different types of PTO in operation: a non shear, shear pin and slip clutch — the last being the most expensive. Implement end of non shear (r) and shear type (l) Non shear: this is a solid yoke to yoke set up and used with the expectation that certain equipment will not encounter any sudden stops. I figure that the finishing mower does not need a shear set up as the blades will slip to a degree being belt driven and my other mower, the flail mower, is extremely forgiving in its design.

-

Lead Time

: -

Quantity(Bags) 1 – 50 >50 Est. Time(days) 15 To be negotiated

Online Customization

| TYPE | BM3Y-80 | BM3Y-100 | BM3Y-125 | BM3Y-160 | BM3Y-200 | BM3Y-250 | BM3Y-315 | BM3Y-400 | BM3Y-500 | |

| BM3YS-80 | BM3YS-100 | BM3YS-125 | BM3YS-160 | BM3YS-200 | BM3YS-250 | BM3YS-315 | BM3YS-400 | BM3YS-500 | ||

| BM3YW-80 | BM3YW-100 | BM3YW-125 | BM3YW-160 | BM3YW-200 | BM3YW-250 | BM3YW-315 | BM3YW-400 | BM3YW-500 | ||

| Displacement(ml/r) | 80.5 | 100.5 | 126.3 | 160.8 | 200.9 | 252.6 | 321.5 | 401.9 | 476.5 | |

| Max.Pressure.Drop(Mpa) | cont. | 20.5 | 20.5 | 20.5 | 20.5 | 20.5 | 20 | 20 | 15.5 | 12 |

| int. | 27.5 | 27.5 | 27.5 | 26 | 25 | 25 | 24 | 19 | 14 | |

| peak. | 29.5 | 29.5 | 29.5 | 28 | 27 | 27 | 26 | 21 | 16 | |

| Max.torque(N.m) | cont. | 226 | 282 | 355 | 451 | 564 | 684 | 870 | 813 | 728 |

| int. | BREATHER DESIGN Although there are dozens of stock breathers and vent plugs on the market, EPT testing found none to be totally effective under all operating conditions. Variables such as input/output speed, direction of rotation, oil level and viscosity, and reducer mounting position all affect breather performance.293 | 365 | 459 | 559 | 672 | 845 | 1032 | 1021 | 903 | |

| peak. | 306 | 383 | 481 | 588 | 708 | 891 | 1091 | 1141 | 1044 | |

| Max. Speed (cont.)(r/min) |

805 | 745 | 590 | 465 | 370 | 295 | 230 | 185 | 155 | |

| Max.Flow(cont.)(L/min) | 65 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | |

| Max.Output.Power(cont.)(Kw) | 16 | 18 | 18 | 18 | 18 | 18 | 17 | 11 | 9 | |

| Weight(kg) | 9.8 | 10 | 10.3 | 10.7 | 11.1 | 11.6 | 12.3 | 13.2 | 14.3 | |

The company was certified by ISO9001:2008 Quality Management System.

The company was certified by ISO9001:2008 Quality Management System.

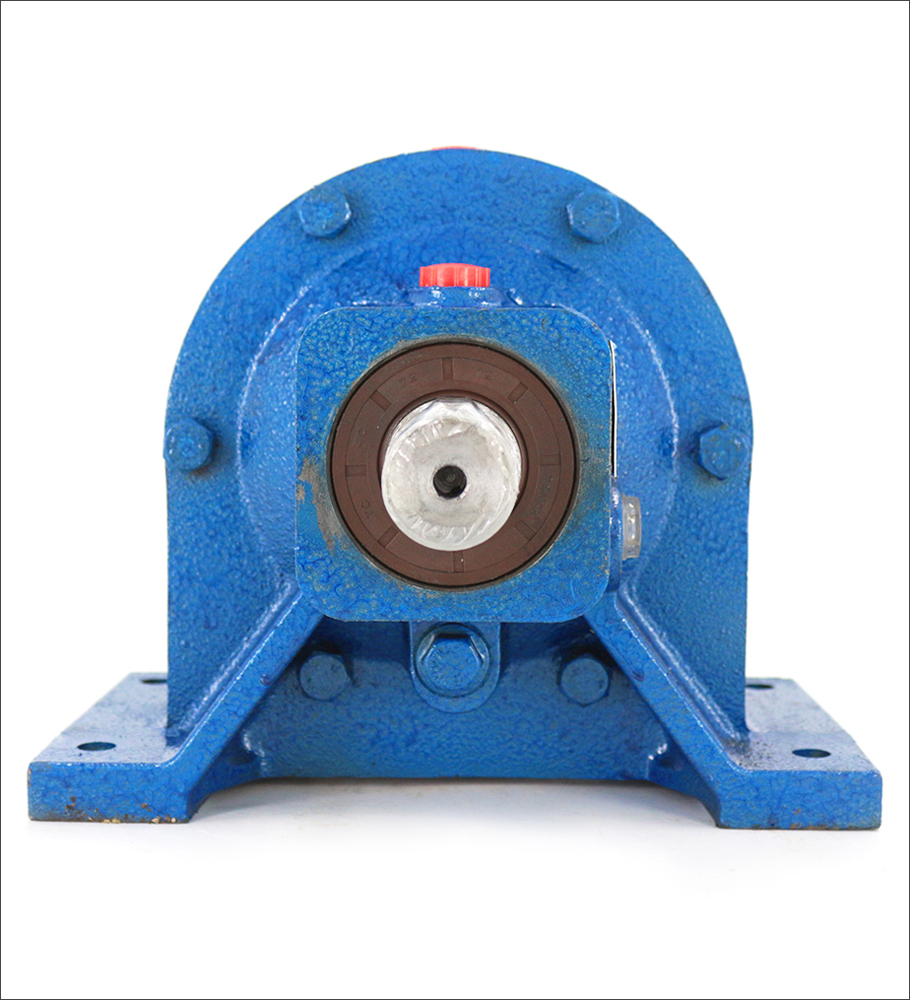

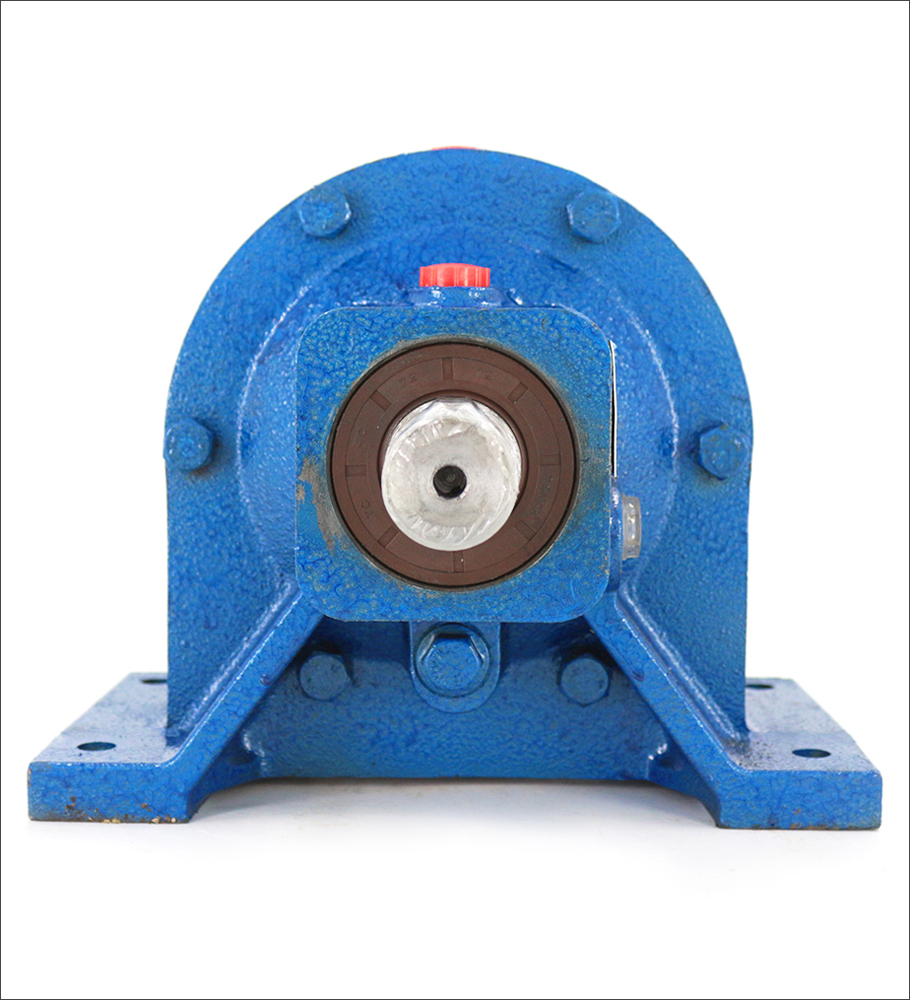

Best China manufacturer & factory Premium quality cycloidal speed reducer BWD2 cycloid gearbox with motor With high quality best price

EVER-POWER GROUP CO., LTD. IS SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, PARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAULIC SYSTEM, VACCUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND pto shaft, agricultural gearboxes SO ON.

Overview

Quick Details

- Applicable Industries:

-

Our company is located in XiHu HangZhou Zhejiang Province. T

Manufacturing Plant

- ITEM NO:

-

SYF

- Color:

-

Blue

- Product name:

-

BLD Cycloid Speed Reducer

- Application:

-

Machine Tool

- Material:

-

Steel

- Bearing:

-

NSK

- Certificate:

-

ISO9001

- Ratio:

-

9-28800

- Mounting Position:

-

Horizontal (foot Mounted)

- Input Form:

-

IEC Flange

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 1000 >1000 Est. Time(days) 10 To be negotiated

Online Customization

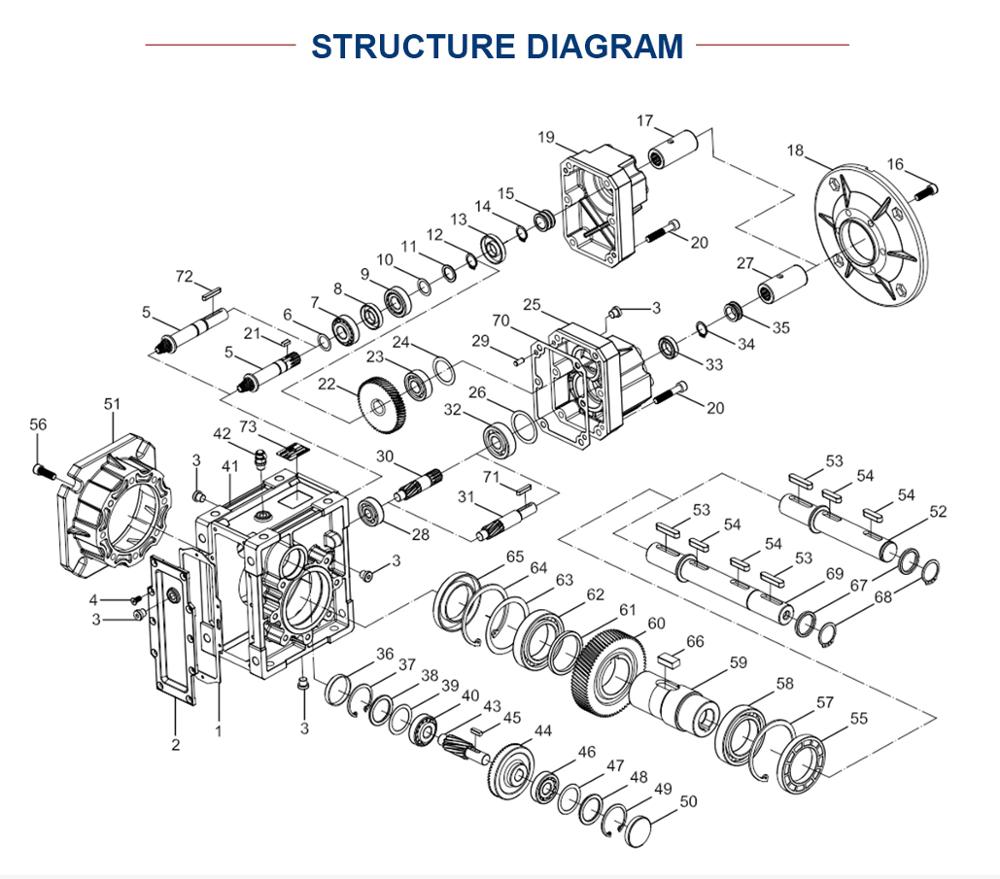

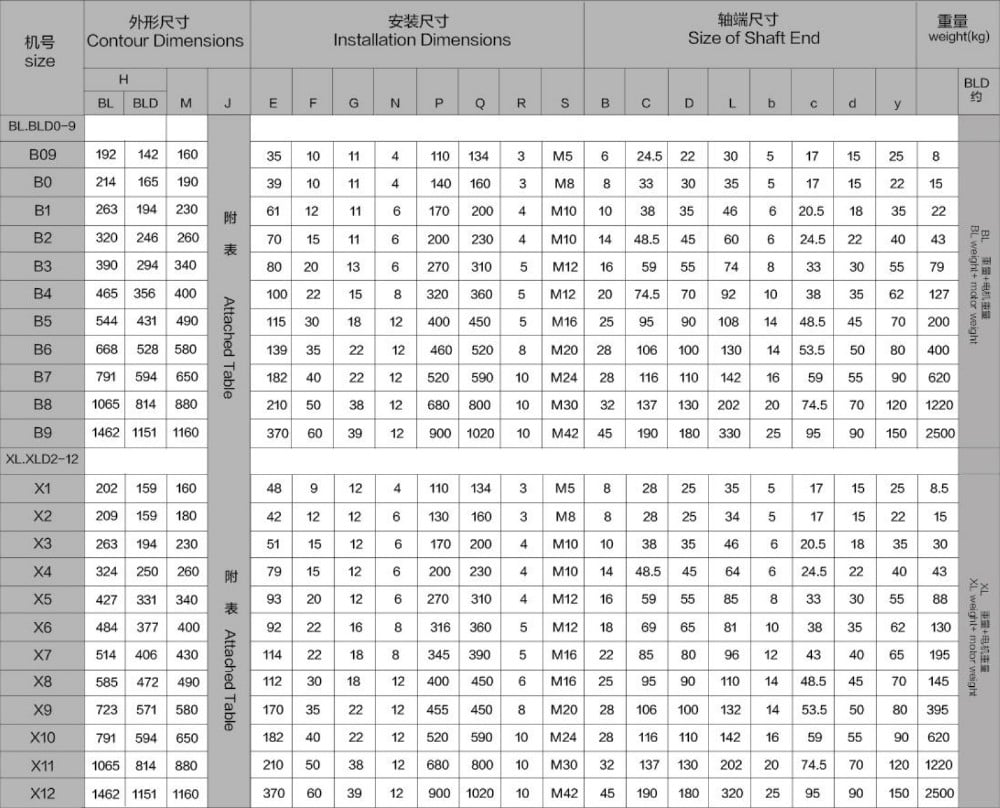

Product Description

Cycloidal gear reducer is a principle adopted K-H-V Planetary Gear less innovative gear. Its transmission process as follows : input shaft equipped with a 180-degree dislocation of the double eccentric sets, replaced with two eccentric turn as a roller bearing arm, the formation of H-, two cycloid round hole at the center shall uplink Eccentric Roller Bearings arm, which cycloidal gear needle round and meshing phase, comprising a difference of the teeth meshing with the gearbox.

|

Type |

stage |

Model |

Ratio |

Nominal Power (KW) |

Nominal Torque(N.m) |

|

X/B Series Cycloidal Reducer |

Single reducer |

B09/X1 |

9-87 |

0.55-0.18 |

26-50 |

|

B0/X2 |

1.1-0.18 |

58-112 |

|||

|

B1/X3 |

0.55-0.18 |

117-230 |

|||

|

B2/X4 |

4-0.55 |

210-400 |

|||

|

B3/X5 |

11-0.55 |

580-1010 |

|||

|

B4/X6/X7 |

11-2.2 |

580-1670 |

|||

|

B5/X8 |

18.5-2.2 |

1191-3075 |

|||

|

B6/X9 |

15-5.5 |

5183-5605 |

|||

|

B7/X10 |

11-45 |

7643 |

|

Type |

stage |

Model |

Ratio |

Nominal Power (KW) |

Nominal Torque(N.m) |

|

X/B Series Cycloidal reducer |

Double reducer |

B10/X32 |

99-7569 |

0.37-0.18 |

175 |

|

B20/X42 |

1.1-0.18 |

600 |

|||

|

B31/X53 |

2.2-0.25 |

1250 |

|||

|

B41/X63 |

2.2-0.25 |

1179-2500 |

|||

|

B42/X64 |

4-0.55 |

2143-2500 |

|||

|

B52/X84 |

4-0.55 |

2143-5000 |

|||

|

B53/X85 |

7.5-0.55 |

5000 |

|||

|

B63/X95 |

7.5-0.55 |

5893-8820 |

|||

|

B74/X106 |

11-2.2 |

11132-12000 |

|||

|

B84/X117 |

11-2.2 |

11132-16000 |

Main Features

All planetary cycloidal reducer rotating device can be divided into three parts:input part,deceleration part and output part.

Dislocation on the input shaft is equipped with a 180℃ of double eccentric sleeve,equipped with two ball bearings on the eccentric sleeve,the formation of H two cycloid gear center hole is the eccentric sleeve on the turning arm bearing raceway,and by a groud of cycloid gear and pin gear ring of gear meshing,less bad tooth meshing reduction mechanism to form,(in order to reduce friction,in small ratio of speed reducer,the needle with needle teeth on the gear set).

When the input shaft with eccentric sleeve rotation for a week,as a result of the cycloid gear tooth profile curve characteristics and restricted by needle on the gear teeth,the movement of the cycloid gear becoming both revolution and rotation of the plane movement,and input shaft are

made for a week,eccentric sleeve also turn the week,cycloid gear in the opposite direction around a big tooth difference reduction is obtained, then with the help pf W output mechanism,the cycloid gear rotates at low speed movement through the pin shaft,passed to the output shaft,low output speed can be achieved.

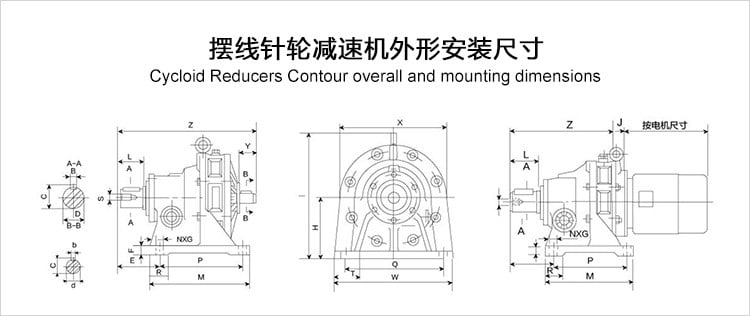

The Designation of Cycloidal Reducers

Example: BL(E)D41-1225-0.37-WB: B series cyclo drive gearboxL: Vertical mounted with flange, Shaft downward(E): None-one stage, E-two stage, S-three stageD:Standard electric motors41: Model number 411225: Speed Reduction Ratio

0.37: Electric motor power:0.37kwW: Mounting way.

Basic Parameters

Power range: 0.25 – 90kW

Output speed(r/min): 0.011 – 161Output Torque(N.M): Top to 22920N.m

All models of this cycloidal motor reducer are

BW0、、BWD0、BW1、BWD1、BW2、BWD2、BW3、BWD3、BW4、BWD4、BW5、BWD5、BW6、BWD6、BW7、BWD7、BW8、BWD8、BW9、BWD9、BL0、BLD0、BL1、BLD1、BL2、BLD2、BL3、BLD3、BL4、BLD4、BL5、BLD5、BL6、BLD6、BL7、BLD7、BL8、BLD8、BL9、BLD9、

BWE20、BWED20、BWE30、BWED30、BWE31、BWED31、BWE41、BWED41、BWE42、BWED42、BWE52、BWED52、BWE53、BWED53、BWE63、BWED63、BWE74、BWED74、BWE85、BWED85、BWE95

BW12、BWD12、BW15、BWD15、BW18、BWD18、BW22、BWD22、BW27、BWD27、BW33、BWD33、BW39、WD39、BW45、BWD45、BW55、BWD55、

BL12、BLD12、BL15、BLD15、BL18、BLD18、BL22、BLD22、BL27、BLD27、BL33、BLD33、BL39、LD39、BL45、BLD45、BL55、BLD55、

BWE1512、BWED1512、BWE1812、BWED1812、BWE2212、BWED2212、BWE2215、BWED2215、BWE2715、BWED2715、BWE2718、BWED2718、BWE3318、BWED3318

XW0、XW1、XW2、XW3、XW4、XW5、XW6、XW7、XW8、XW9、XW10、XW11、XW12

XWD1、XWD2、XWD3、XWD4、XWD5、XWD6、XWD7、XWD8、XWD9、XWD10、XWD11、XWD12

XL0、XL1、XL2、XL3、XL4、XL5、XL6、XL7、XL8、XL9、XL10、XL11、XL1

XLD1、XLD2、XLD3、XLD4、XLD5、XLD6、XLD7、XLD8、XLD9、XLD10、XLD11、XLD12

XWED20、XWED32、XWED42、XWED53、XWED63、XWED74、XWED84、XWED85、XWED95、XWED106、XWED128

XLE20、XLE32、XLE42、XLE53、XLE63、XLE74、XLE84、XLE85、XLE95、XLE106、XLE128

XLED20、XLED32、XLED42、XLED53、XLED63、XLED74、XLEDK84、XLED85、XLED95、XLED106、XLED128

XJ0、JXJ0、XJ1、JXJ1、XJ2、JXJ2、XJ3、JXJ3、XJ4、JXJ4、XJ5、JXJ5、XJ6、JXJ6、

XJL0、JXJL0、XJL1、JXJL1、XJL2、JXJL2、XJL3、JXJL3、XJL4、JXJL4、XJL5、JXJL5、XJL6、JXJL6、XJE10、JXJE10、XJE20、JXJE20、XJE31、JXJE31、XJE41、JXJE41、XJE42、JXJE42、XJE52、JXJE52、XJE53、JXJE53、XJE63、JXJE63、

XJLE10、JXJLE10、XJLE20、JXJLE20、XJLE31、JXJLE31、XJLE41、JXJLE41、XJLE42

Reduction ratio mainly is 7,9,11,17,23,29,35,43,59,71,87,99,121,187,289,391,493,595,731,841,1003,1225,1505,1849,2065,2537,3481,4189,5133,7569.

Paint Color: Various

Material: Rugged cast iron or ductile housings

Lubrication: Grease or oil lubricated models available.

Seals: Nitrile material, dual lipped, double output seals available.

Working: 24 hours continuous available and shaft forward reverse

Reducer Reduction: Internal planetary gear mechanism with trochoidal curved tooth profile.

Atmosphere: Well ventilated location, free of corrosive gases, explosive gases, vapors and dust

Application :

• Conveyors • Sawmills and Wood Mills • Food Machinery • Wastewater Treatment• Mixers • Steel Mills • Automotive Plants • Construction Equipment• Paper Mills • Recycling Machines • Poultry Plants • Processing Plants• Oil Press Machine • Rotary Feeder

What are our unique advantages in making Cycloidal Reducers your choice factory infrastructure investment?

we can help you:

● Providing proper type gearbox and combined gearbox to meet your application needs;

● Better managing maintenance cost and lifting operation efficiency;

● Improving production capacity and boosting economic profitability.

cycloidal gear reducer is widely used in many industries such as Textile manufacturing and food industry. it is small but very good quality. This kind of gear reducer can divided into three parts, the input , the reduction part and the output shaft. There is a double eccentric locking collars in the input part. when input shaft turns a round, the eccentric locking collars will also turns a round so that transfer to the reduction part. to make the output shaft turns. so it make torques. Efficiency can get to 95% . Usually, there are two mounting way and this is vertical mounting.It can be widely used in industry of Coal, steel, machinery, chemical, textile, mixer etc. This can have one stage, two stages and three stages reduction gear. If you want it with flange, we can make. the price with flange or without flange is same.

How to choose a proper type of Gearbox : It is recommended that as much as possible of the following information be given in the enquiry or order so that a check can be made and advice given on the most suitable size of Worm Speed Reducer for any application.1.Type of prime mover.2. Horse-power of prime mover.3. Output torque required from driven member. 4. Input speed of gear unit.5. Output speed of gear unit. 6. Configuration of drive required and shaft disposition. 7. Total daily hours of running. If running is intermitteTo get the type-choose reference,please contact our technical rep or sales rep .

Characteristics:

1.Cycloid reducer big reduction ratio, high efficiency: a reduction gear ratio is 9~87, the two-stage reduction gear ratio is 121 ~ 5133, multistage combination can reach tens of thousands, and the needle tooth meshing line type rolling friction, the meshing surface no relative sliding, so a reduction efficiency of 94%.

2.Pin wheel reducer smooth running, low noise: the teeth contact at the same time when in operation, the coincidence degree high, stable running, strong overload capacity, low vibration and noise, a variety of models, small noise.

3. The use of reliable, long life: because the main part is made of high carbon alloy steel quenching (HRC58-62), and then grinding, and cycloid gear and pin gear set mesh transfer to the pin gear form rolling friction pair, friction coefficient is small, so that the meshing zone no relative sliding, wear small, so durable.

4. Compact structure, small volume: compared with other reducer with the power of the above weight, small volume 1/3, as is the planetary transmission, the input shaft and the output shaft in the same axis, in order to obtain the smallest possible size.

Cycloidal drive vs. planetary gear To eliminate contact-pattern inconsistencies, EPT developed an automated centering machine that accurately measures each worm and gear subassembly, as well as the reducer housing and bearing covers. A computer records the data and calculates the thickness and location of shims required to exactly center the gear under the worm shaft and, at the same time, provides the appropriate end 1play for the output tapered-roller bearings. This maximizes operating efficiency and minimizes temperature rise. When it comes to large transmission ratios in a compact design, two gear types are particularly suitable: The planetary gear and the cycloidal drive. The similarities between the two gear types become particularly clear when the ring gear of the planetary gearbox is fixed. The gearbox is driven by the sun gear and the output is done by the carrier.Animation: Operating principle of a planetary gear with fixed ring gearIn the case of the planetary gear, the rotary axes are the axes of the planet gears (shown in blue) and in the case of the cycloidal gear, the axes of the cycloidal discs. While the planet gears are driven by a sun gear, the cycloid discs are driven by an eccentric shaft. As they rotate, the planet gears move around the inside of the ring gear. In the same way, the cycloid discs rotate around the fixed pins arranged in a circle. The motion of the planet gears drives the carrier and transmits the power to the output shaft. In the same way, the motion of the cycloidal discs drives a pin disc, which in turn transmits the power to the output shaft. Planetary gear Cycloidal drivemoving axlesplanet gears cycloidal discsdriven by sun gear eccentric shaftorbiting ring gear fixed ring pinsdriving the carrier pin disc

Compared to planetary gears, cycloidal drives are very robust against shock loads. In addition, cycloidal drives achieve significantly better positioning accuracy due to their very low backlash and high torsional stiffness. Therefore cycloidal drives are ideally suited for all types of drive technologies (e.g. for servo motors in robotics) and especially for heavy loads.Cycloidal drives generally have a lower mass and a more compact design than planetary gears, especially at high transmission ratios, and have a longer service life. At relatively low gear ratios of less than 20, however, planetary gears usually offer better advantages and higher efficiency, depending on the application.

Our Company

HangZhouYinxin Electromechanical Facilities Co. Ltd

HangZhouYinxin Electromechanical Equipment Co., Ltd.is a gift enterprise integrating development, design, production and sales,Main promoting products include reducer motor,water pump,construction machinery and parts,bearings,hardware and electrical equipment,plastic products,Labour protection appliance.Our company always follow the operation concept which contains people-oriented, innovation as the soul,be prepared for danger in times of peace, unremitting……

Application area

What do our customers use Cycloidal Drives for?Cycloidal Drive Gear Motor for Travel Motors in Automated Guided VehiclesCycloidal Drive Gear Motor for Production Line Conveyor SystemsCycloidal Drive Gear Motor for Chemical Industry Mixers & AgitatorsCycloidal Drive Gear Motor for Pumping, Cooling & Lubrication SystemsCycloidal Drive Gear Motor for Metalworking MachinesCycloidal Drive Gear Motor for Construction MachineryGear Motor for Water Treatment PlantsGear Motor for Recycling MachineryGear Motor for Steel Industry ProductionCycloidal Drive Gear Motor for Sawmills and Woodworking MachinesCycloidal Drive Gear Motor for Food & Sugar Industry Production LinesCycloidal Drive Gear Motor for Heavy Materials Transportation in Rolling MillsCycloidal Drive Gear Motor for Paper Industry Production Lines

Certifications

Sales territory

Packing & Delivery

|

Packaging |

||

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

|

Weight |

1.2 T |

|

|

Packaging Details |

The normal package is wooden box(SizeIn our company we are aware of the importance of the users’ safety. That’s why our PTO’s are produced according to legal regulations and European directives and bear the CE sign. A key factor for safety assurance is the accession in the products’ development phase. By all means, the users’ knowledge about the correct use of a PTO drive shaft is vital. This means, that every users’ duty is to read and follow the safety instructions.: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

|

|

Packaging |

||

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

|

Weight |

1.2 T |

|

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

|

FAQ

Q1: Are you trading company or manufacturer ?

A: We are a manufacturer in ZJ China.welcome to our factory to have a visit.

Q2: How we select models and specifications?

A:You can email us the series name & code (for example: WJ series worm gearbox) as well as requirement details, such as motor power, output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings, it is better.

Q3: How is your price? Can you offer any discount?

A: We will give the best price we can base on your needs and the quantities.

Q4: How long should I wait for the feedback after I send the enquiry?

A: Within 12 hours.

Q5: What is your product warranty period?

A:We offer one year warranty since the vessel departure date left China.

Q6: What industries are your gearboxes being used?

A:Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

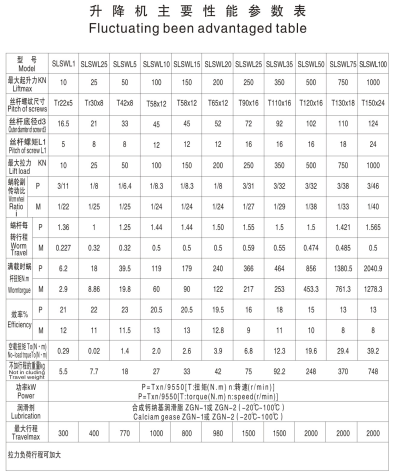

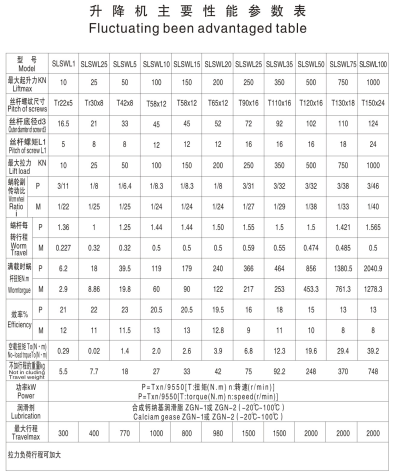

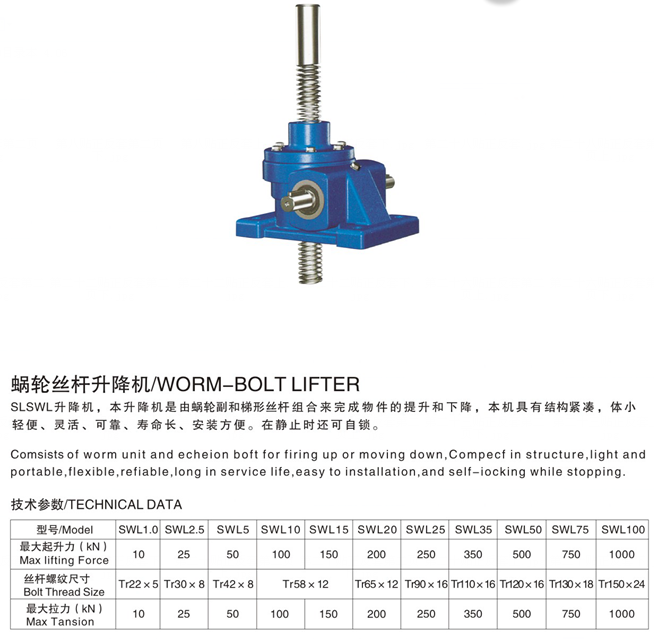

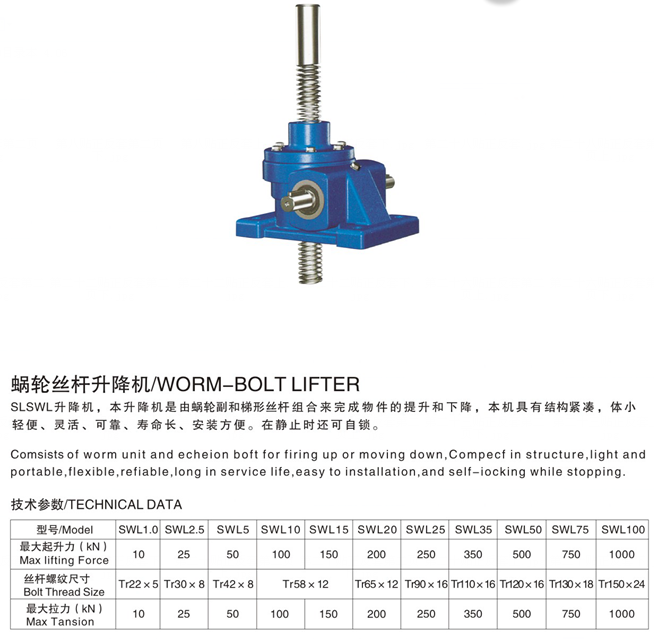

Best China manufacturer & factory SWL series worm gear nut travel 90 degree screw small lifting jacks for lifting motor speed reducer With high quality best price

We are aiming to meet the demands of the clients around the world.. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

worm

- Output Torque:

-

50~2300Nm

- Input Speed:

-

1400rpm

- Output Speed:

-

14-280rpm

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Certification:

-

ISO9001-2008

- Lifting Capacity:

-

As request

- LiftiEPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery cutting tools. ng Height(mm):

-

As request

- Overall Width(mm):

-

As request

- Gear material:

-

Low carbon high alloy steel

- Heat treatment:

-

Carburising, quenching, gear grinding

- Diameter & Length of Screw:

-

Designed as request

- Bearing:

-

C&U

- gear precision grade:

-

din 4

We get a lot of questions surrounding PTO shafts and how to attach them to your tractor. In today’s post, we’ll cover the basics of PTO, PTO Shafts, and PTO adapters for your tractor mounted implements. PTO stands for “Power Take-Off” and is the primary mechanism for providing power to an attachment or implement (such as a flail mower) via PTO shaft.By providing rotational energy through the driveshaft (or cardan shaft) a variety of tractor mounted implements can be operated by small and mid-sized tractors.

Supply Ability

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Standard exporting package

- Port

- Ningbo Port, Shanghai Port

Online Customization

SWL series worm gear nut travel 90 degree screw small lifting jacks for lifting motor speed reducer

Product Description

Advantage:

SWL Worm-bolt lifter has the features of compacted structure, light and portable, flexible, reliable, long service life, easy to installation, and self-locking while stop.

Application Industries:

SWL series screw jacks are widely used in industries such as metallurgy,mining,hoisting and transportation, electrical power,energy source, construction and building material,light industry and traffic industry

| Certification | ISO9001-2008 |

| Lifting Capacity | As request |

| Lifting Height(mm) | As request |

| Overall Width(mm) | As request |

| Gear material | Low carbon high alloy steel |

| Heat treatment | Carburising, quenching, gear grinding |

| Diameter & Length of Screw | Designed as request |

| Bearing | C&U |

| gear precision grade | din 4 |

Company Information

Certifications

Our Services

Packaging & Shipping

Related Products

FAQ

: Are you trading company or manufacturerTo eliminate contact-pattern inconsistencies, EPT developed an automated centering machine that accurately measures each worm and gear subassembly, as well as the reducer housing and bearing covers. A computer records the data and calculates the thickness and location of shims required to exactly center the gear under the worm shaft and, at the same time, provides the appropriate end 1play for the output tapered-roller bearings. This maximizes operating efficiency and minimizes temperature rise. ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact us