Product Description

Product Description

Product Parameters

| product | Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine tools |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2 .Do you accept small order?

If your order bearings are our standard size, we accept even 1pcs.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can flexible couplings accommodate variable operating conditions and loads?

Yes, flexible couplings are designed to accommodate variable operating conditions and loads in mechanical systems. They offer several features that allow them to adapt to changing conditions and handle different loads effectively. Below are the reasons why flexible couplings are well-suited for such applications:

Misalignment Compensation: Flexible couplings can handle misalignment between shafts, including angular, parallel, and axial misalignment. This capability allows them to accommodate slight shifts in shaft positions that may occur due to thermal expansion, vibration, or other factors, ensuring smooth operation even in changing conditions.

Shock and Vibration Absorption: Flexible couplings can dampen shocks and vibrations that result from sudden changes in load or operating conditions. The flexible element in the coupling acts as a buffer, absorbing and reducing the impact of sudden loads or transient forces, protecting connected equipment and increasing system reliability.

Variable Load Capacity: Flexible couplings come in various designs and materials, each with its load capacity range. Manufacturers provide different coupling models with varying load capacities to accommodate different applications. Properly selecting the right coupling for the specific load conditions ensures reliable power transmission even under varying loads.

Compensation for Thermal Expansion: Temperature changes can cause thermal expansion in mechanical systems, leading to shaft misalignment. Flexible couplings can handle the resulting misalignment, compensating for thermal expansion and ensuring continuous and smooth power transmission.

Torsional Stiffness: Flexible couplings are designed with a balance between flexibility and torsional stiffness. This property allows them to adapt to variable loads while still providing the necessary rigidity for efficient power transmission.

Durable Materials and Designs: Manufacturers produce flexible couplings from durable materials like stainless steel, aluminum, or engineered elastomers. These materials ensure that the couplings can withstand varying operating conditions, including temperature fluctuations, harsh environments, and high loads.

Dynamic Behavior: Flexible couplings have a dynamic behavior that enables them to operate smoothly and efficiently under changing loads and speeds. They can handle variations in rotational speed and torque while maintaining consistent performance.

Application Flexibility: Flexible couplings find applications in a wide range of industries, from automotive and aerospace to industrial and marine. Their versatility allows them to accommodate variable operating conditions and loads in different systems.

Summary: Flexible couplings are well-suited for applications with variable operating conditions and loads. Their ability to compensate for misalignment, absorb shocks and vibrations, and handle thermal expansion make them reliable components in mechanical systems. The availability of various coupling designs and materials allows for the selection of the appropriate coupling based on the specific application requirements, ensuring optimal performance and longevity in variable conditions.

Can flexible couplings be used in high-temperature environments, such as furnaces and kilns?

Flexible couplings can be used in high-temperature environments, such as furnaces and kilns, but the selection of the appropriate coupling is crucial to ensure reliable performance and longevity under these extreme conditions. Here are some key considerations:

- Material Selection: The choice of materials is critical when using flexible couplings in high-temperature applications. Look for couplings made from heat-resistant materials that can withstand the elevated temperatures without experiencing significant degradation. Common materials used for high-temperature couplings include stainless steel, high-temperature alloys, and certain types of elastomers designed for heat resistance.

- Lubrication: High temperatures can cause lubricants to break down or evaporate more quickly. Some flexible couplings may require specialized high-temperature lubricants to ensure smooth operation and reduce wear at elevated temperatures. Check the manufacturer’s recommendations for lubrication in high-temperature environments.

- Thermal Expansion: In high-temperature applications, the equipment and shafts may experience thermal expansion, leading to misalignment. Flexible couplings with higher misalignment capabilities may be necessary to accommodate these thermal effects and prevent additional stress on the system.

- Torsional Stiffness: Consider the required torsional stiffness for the specific application. In high-temperature environments, couplings may experience changes in stiffness due to temperature variations. It is essential to choose a coupling with appropriate torsional characteristics for the intended operating temperature range.

- Application Specifics: Evaluate the specific operating conditions of the furnace or kiln, including the maximum and fluctuating temperatures, vibration levels, and potential exposure to chemicals or other harsh elements. Choose a coupling that can withstand these conditions without compromising performance or safety.

- Coupling Type: Different types of flexible couplings offer varying degrees of heat resistance and performance capabilities. For example, certain types of disc couplings or metal bellows couplings are more suitable for high-temperature environments due to their robust construction and resistance to heat.

- Regular Maintenance: In high-temperature applications, couplings may be subject to more stress and wear. Regular inspection and maintenance are essential to monitor the coupling’s condition, lubrication, and alignment to ensure it continues to function optimally in the challenging environment.

Overall, flexible couplings can be utilized in high-temperature environments, but it is vital to choose a coupling specifically designed and rated for these conditions. Working closely with coupling manufacturers and considering the specific demands of the application will help ensure that the selected coupling can handle the challenges posed by furnaces, kilns, and other high-temperature equipment, providing reliable power transmission and contributing to the overall efficiency and safety of the system.

Can flexible couplings be used in applications with varying operating temperatures?

Yes, flexible couplings can be used in applications with varying operating temperatures. The suitability of a flexible coupling for a specific temperature range depends on its design and the materials used in its construction. Different types of flexible couplings are available to handle a wide range of temperature conditions, making them versatile for use in various industries and environments.

High-Temperature Applications:

For applications with high operating temperatures, such as those found in certain industrial processes, exhaust systems, or high-temperature machinery, flexible couplings made from materials with excellent heat resistance are used. These materials may include stainless steel alloys, heat-treated steels, or specialized high-temperature elastomers. High-temperature flexible couplings are designed to maintain their mechanical properties, including flexibility and torque transmission capabilities, even at elevated temperatures.

Low-Temperature Applications:

Conversely, for applications in extremely cold environments or cryogenic processes, flexible couplings constructed from materials with low-temperature resistance are employed. These couplings are designed to remain flexible and functional at very low temperatures without becoming brittle or losing their ability to handle misalignment. Some low-temperature couplings may use special polymers or elastomers with excellent cold-temperature performance.

Temperature Range Considerations:

When selecting a flexible coupling for applications with varying operating temperatures, it is essential to consider the specific temperature range in which the coupling will operate. Some flexible couplings have a wider temperature range, allowing them to function effectively in both high and low-temperature environments. However, in extreme temperature conditions, specialized couplings may be necessary to ensure reliable performance and prevent premature failure.

Manufacturer Guidelines:

Manufacturers of flexible couplings provide guidelines and specifications regarding the temperature range of their products. It is crucial to consult the manufacturer’s documentation to ensure that the chosen coupling is suitable for the intended operating temperature of the application. Using a coupling beyond its recommended temperature range can lead to performance issues, reduced efficiency, or even failure.

Applications:

Flexible couplings with varying temperature resistance find use in numerous industries, including aerospace, automotive, manufacturing, power generation, and more. Whether in high-temperature exhaust systems, low-temperature cryogenic processes, or regular industrial applications with temperature fluctuations, flexible couplings play a vital role in providing reliable power transmission and misalignment compensation.

In summary, flexible couplings can be effectively used in applications with varying operating temperatures, provided that the coupling’s design and material properties align with the specific temperature requirements of the application.

editor by CX 2024-04-09

China OEM Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine Tools

Product Description

Product Description

Product Parameters

| product | Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine tools |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2 .Do you accept small order?

If your order bearings are our standard size, we accept even 1pcs.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What role does a flexible coupling play in minimizing wear and tear on connected components?

A flexible coupling plays a vital role in minimizing wear and tear on connected components by absorbing and mitigating various mechanical stresses that occur during operation. Here’s how a flexible coupling achieves this:

- Misalignment Compensation: One of the primary causes of wear and tear on rotating machinery is misalignment between connected shafts. Misalignment can occur due to factors such as thermal expansion, foundation settling, or assembly errors. A flexible coupling can accommodate both angular and parallel misalignments, reducing the stress on the shafts and connected components. By allowing for misalignment, the coupling prevents excessive forces from being transmitted to the connected components, minimizing wear.

- Vibration Damping: During operation, rotating machinery can generate vibrations that lead to accelerated wear on components like bearings, gears, and couplings. A flexible coupling acts as a vibration damper, absorbing and dispersing vibrations, reducing their impact on connected components. This damping effect helps prevent fatigue and extends the life of the components.

- Shock Absorption: Machinery may experience sudden shocks or impact loads during start-ups, shutdowns, or due to external factors. A flexible coupling is designed to absorb and cushion these shocks, preventing them from propagating through the system and causing damage to sensitive components.

- Smooth Torque Transmission: In rigid couplings, torque transmission between shafts can be abrupt and cause torque spikes. These spikes put stress on the connected components, leading to wear and fatigue. Flexible couplings transmit torque smoothly, without sudden spikes, ensuring even distribution of forces and reducing the wear on components.

- Controlling Torsional Vibrations: Torsional vibrations, a type of vibration that affects rotating shafts, can be damaging to connected components. Some flexible couplings are designed to address torsional vibration issues, providing additional protection against wear and tear.

- Compensating for Thermal Expansion: Temperature fluctuations can lead to thermal expansion or contraction of machinery components. A flexible coupling can accommodate these changes, preventing undue stress on the connected components that may arise from differential expansion rates.

By performing these functions, a flexible coupling acts as a protective barrier for connected components, minimizing wear and tear, and contributing to their longevity. The reduced wear and stress on the components also result in lower maintenance costs and improved overall reliability of the mechanical system.

How does a flexible coupling handle torsional vibrations in rotating machinery?

A flexible coupling is designed to handle torsional vibrations in rotating machinery by providing a degree of flexibility and damping. Torsional vibrations are oscillations that occur in the drivetrain due to torque variations, sudden load changes, or other transient events. These vibrations can lead to resonance, excessive stress, and premature failure of components.

Flexible couplings mitigate torsional vibrations through the following mechanisms:

- Torsional Compliance: Flexible couplings have an element, such as an elastomeric insert, that can deform or twist to absorb torsional shocks. When the drivetrain experiences torsional vibrations, the flexible element flexes, effectively isolating and dampening the vibrations before they propagate further.

- Damping: Many flexible couplings have inherent damping properties, especially those with elastomeric components. Damping dissipates the energy of the torsional vibrations, reducing their amplitude and preventing resonance from occurring.

- Tuned Design: Some flexible couplings are specifically designed with specific torsional characteristics to match the drivetrain’s requirements. By tuning the coupling’s stiffness and damping properties, engineers can ensure optimal torsional vibration control.

- Torsional Stiffness: While flexible couplings provide flexibility to absorb vibrations, they also offer a degree of torsional stiffness to maintain the torque transmission efficiency between the shafts.

It is important to select the appropriate flexible coupling based on the specific torsional characteristics and requirements of the rotating machinery. Different applications may demand different types of couplings with varying levels of flexibility and damping. High-performance flexible couplings can effectively minimize torsional vibrations, protecting the drivetrain and connected equipment from excessive stress and potential damage.

Additionally, proper alignment of the flexible coupling during installation is crucial to ensure its optimal performance in mitigating torsional vibrations. Misalignment can introduce additional stresses and exacerbate torsional issues in the system. Regular inspection and maintenance of the flexible coupling will help identify any signs of wear or damage that may affect its ability to handle torsional vibrations effectively.

What are the differences between elastomeric and metallic flexible coupling designs?

Elastomeric and metallic flexible couplings are two distinct designs used to transmit torque and accommodate misalignment in mechanical systems. Each type offers unique characteristics and advantages, making them suitable for different applications.

Elastomeric Flexible Couplings:

Elastomeric flexible couplings, also known as flexible or jaw couplings, employ an elastomeric material (rubber or similar) as the flexible element. The elastomer is typically molded between two hubs, and it acts as the connector between the driving and driven shafts. The key differences and characteristics of elastomeric couplings include:

- Misalignment Compensation: Elastomeric couplings are designed to handle moderate levels of angular, parallel, and axial misalignment. The elastomeric material flexes to accommodate the misalignment while transmitting torque between the shafts.

- Vibration Damping: The elastomeric material in these couplings offers excellent vibration dampening properties, reducing the transmission of vibrations from one shaft to another. This feature helps protect connected equipment from excessive vibrations and enhances system reliability.

- Shock Load Absorption: Elastomeric couplings can absorb and dampen shock loads, protecting the system from sudden impacts or overloads.

- Cost-Effective: Elastomeric couplings are generally more cost-effective compared to metallic couplings, making them a popular choice for various industrial applications.

- Simple Design and Installation: Elastomeric couplings often have a straightforward design, allowing for easy installation and maintenance.

- Lower Torque Capacity: These couplings have a lower torque capacity compared to metallic couplings, making them suitable for applications with moderate torque requirements.

- Common Applications: Elastomeric couplings are commonly used in pumps, compressors, fans, conveyors, and other applications that require moderate torque transmission and misalignment compensation.

Metallic Flexible Couplings:

Metallic flexible couplings use metal components (such as steel, stainless steel, or aluminum) to connect the driving and driven shafts. The metallic designs can vary significantly depending on the type of metallic coupling, but some general characteristics include:

- High Torque Capacity: Metallic couplings have higher torque transmission capabilities compared to elastomeric couplings. They are well-suited for applications requiring high torque handling.

- Misalignment Compensation: Depending on the design, some metallic couplings can accommodate minimal misalignment, but they are generally not as flexible as elastomeric couplings in this regard.

- Stiffer Construction: Metallic couplings are generally stiffer than elastomeric couplings, offering less vibration dampening but higher torsional stiffness.

- Compact Design: Metallic couplings can have a more compact design, making them suitable for applications with limited space.

- Higher Precision: Metallic couplings often offer higher precision and concentricity, resulting in better shaft alignment.

- Higher Cost: Metallic couplings are typically more expensive than elastomeric couplings due to their construction and higher torque capacity.

- Common Applications: Metallic couplings are commonly used in high-speed machinery, precision equipment, robotics, and applications with high torque requirements.

Summary:

In summary, the main differences between elastomeric and metallic flexible coupling designs lie in their flexibility, torque capacity, vibration dampening, cost, and applications. Elastomeric couplings are suitable for applications with moderate torque, misalignment compensation, and vibration dampening requirements. On the other hand, metallic couplings are chosen for applications with higher torque and precision requirements, where flexibility and vibration dampening are less critical.

editor by CX 2024-03-06

China wholesaler Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine Tools

Product Description

Product Description

Product Parameters

| product | Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine tools |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2 .Do you accept small order?

If your order bearings are our standard size, we accept even 1pcs.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can flexible couplings be used in hydraulic and pneumatic systems?

Yes, flexible couplings can be used in both hydraulic and pneumatic systems to connect various components and transmit power or motion. However, the selection of flexible couplings for these systems depends on specific application requirements and operating conditions.

Hydraulic Systems:

- Compensating Misalignment: In hydraulic systems, flexible couplings are used to compensate for misalignment between the driving and driven components, such as pumps, motors, and actuators. Misalignment can occur due to variations in the mounting or movement of components. The flexibility of the coupling allows it to accommodate misalignment while transmitting torque efficiently.

- Vibration Damping: Hydraulic systems can generate vibrations during operation, which can affect the performance and lifespan of connected components. Flexible couplings with vibration-damping properties help reduce the transmission of vibrations, providing smoother operation and minimizing wear on components.

- Reducing Shock Loads: Flexible couplings absorb and dampen shock loads that may occur in hydraulic systems during rapid starts, stops, or pressure fluctuations. By absorbing these shock loads, the coupling protects connected components from potential damage.

- Corrosion Resistance: Hydraulic systems may operate in environments with exposure to hydraulic fluids, which can be corrosive. Flexible couplings made of materials resistant to corrosion, such as stainless steel or specific polymers, are suitable for such applications.

- High Torque Transmission: Hydraulic systems often require high torque transmission between the power source and the driven components. Flexible couplings can handle high torque levels while accommodating angular and axial misalignments.

Pneumatic Systems:

- Compensation for Misalignment: In pneumatic systems, flexible couplings provide compensation for misalignment between components, such as pneumatic cylinders, valves, and rotary actuators. The ability to accommodate misalignment ensures smooth operation and reduces the risk of mechanical stress on the system.

- Minimal Lubrication: Some flexible couplings designed for pneumatic systems require little to no lubrication, making them suitable for applications where oil or grease contamination is undesirable.

- Low Inertia: Pneumatic systems often require components with low inertia to achieve rapid response times. Flexible couplings with low mass and low inertia help maintain the system’s responsiveness and efficiency.

- High Torque Transmission: Pneumatic systems can demand high torque transmission between components, such as in pneumatic rotary actuators. Flexible couplings can transmit torque effectively while compensating for potential misalignments.

- Corrosion Resistance: Pneumatic systems operating in harsh environments may be exposed to moisture or chemicals. Flexible couplings made of corrosion-resistant materials are ideal for such conditions.

Overall, flexible couplings are versatile components that can be used in a wide range of hydraulic and pneumatic applications. When selecting a flexible coupling for a specific system, it’s essential to consider factors such as misalignment compensation, vibration damping, shock absorption, corrosion resistance, torque transmission capability, and compatibility with the system’s operating conditions.

Can flexible couplings be used in marine and automotive applications?

Yes, flexible couplings are commonly used in both marine and automotive applications. They offer various advantages that make them suitable for these industries:

- Misalignment Compensation: In marine and automotive systems, there can be misalignments due to factors such as hull flexing in marine vessels or engine movements in vehicles. Flexible couplings can accommodate these misalignments, ensuring efficient power transmission between the engine and the propeller or wheels.

- Vibration Damping: Both marine and automotive environments experience vibrations from engines, propellers, or road conditions. Flexible couplings help dampen these vibrations, reducing wear on components and enhancing the comfort of passengers or crew members.

- Shock Load Absorption: Marine vessels and vehicles can encounter shock loads during operation, especially in rough sea conditions or uneven terrains. Flexible couplings can absorb and dissipate the impact of these shock loads, protecting the drivetrain and transmission components.

- Compact Design: Space is often limited in marine vessels and automotive systems. Flexible couplings come in various compact designs, making them suitable for applications with restricted installation space.

- Corrosion Resistance: Marine environments expose components to corrosive seawater, while automotive systems may encounter exposure to road salt and other corrosive substances. Flexible couplings made from corrosion-resistant materials, such as stainless steel or non-metallic compounds, are ideal for these applications.

- Easy Maintenance: Flexible couplings with self-lubricating features or low maintenance requirements are well-suited for marine and automotive applications, where regular maintenance can be challenging.

- High Torque Capacity: Automotive systems, especially in heavy-duty vehicles, require couplings that can handle high torque levels. Flexible couplings designed for automotive use offer high torque capacity and reliability.

Overall, the adaptability, vibration damping, and misalignment compensation provided by flexible couplings make them suitable for various marine and automotive applications. Whether used in boats, yachts, ships, cars, trucks, or other vehicles, flexible couplings contribute to smooth and reliable power transmission, leading to improved performance and reduced maintenance requirements.

How do flexible couplings compare to other types of couplings in terms of performance?

Flexible couplings offer distinct advantages and disadvantages compared to other types of couplings, making them suitable for specific applications. Here is a comparison of flexible couplings with other commonly used coupling types in terms of performance:

- Rigid Couplings:

Rigid couplings are simple in design and provide a solid connection between two shafts, allowing for precise torque transmission. They do not offer any flexibility and are unable to compensate for misalignment. As a result, rigid couplings require accurate shaft alignment during installation, and any misalignment can lead to premature wear and increased stress on connected equipment. Rigid couplings are best suited for applications where shaft alignment is precise, and misalignment is minimal, such as in well-aligned systems with short shaft spans.

- Flexible Couplings:

Flexible couplings, as discussed previously, excel at compensating for misalignment between shafts. They offer angular, parallel, and axial misalignment compensation, reducing stress on connected components and ensuring smooth power transmission. Flexible couplings are versatile and can handle various applications, from light-duty to heavy-duty, where misalignment, vibration damping, or shock absorption is a concern. They provide a cost-effective solution for many industrial, automotive, and machinery applications.

- Oldham Couplings:

Oldham couplings are effective at compensating for angular misalignment while maintaining constant velocity transmission. They offer low backlash and electrical isolation between shafts, making them suitable for precision motion control and applications where electrical interference must be minimized. However, Oldham couplings have limited capacity to handle parallel or axial misalignment, and they may not be suitable for applications with high torque requirements.

- Gear Couplings:

Gear couplings are robust and can handle high torque levels, making them suitable for heavy-duty applications such as mining and steel mills. They offer good misalignment compensation and have a compact design. However, gear couplings are relatively more expensive and complex than some other coupling types, and they may generate more noise during operation.

- Disc Couplings:

Disc couplings provide excellent misalignment compensation, including angular, parallel, and axial misalignment. They have high torsional stiffness, making them ideal for applications where accurate torque transmission is critical. Disc couplings offer low inertia and are suitable for high-speed applications. However, they may be more sensitive to shaft misalignment during installation, requiring precise alignment for optimal performance.

- Conclusion:

The choice of coupling type depends on the specific requirements of the application. Flexible couplings excel in compensating for misalignment and vibration damping, making them versatile and cost-effective solutions for many applications. However, in situations where high torque, precision, or specific electrical isolation is necessary, other coupling types such as gear couplings, disc couplings, or Oldham couplings may be more suitable. Proper selection, installation, and maintenance of the coupling are essential to ensure optimal performance and reliability in any mechanical system.

editor by CX 2024-02-26

China supplier Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine Tools

Product Description

Product Description

Product Parameters

| product | Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine tools |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2 .Do you accept small order?

If your order bearings are our standard size, we accept even 1pcs.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can flexible couplings accommodate variable operating conditions and loads?

Yes, flexible couplings are designed to accommodate variable operating conditions and loads in mechanical systems. They offer several features that allow them to adapt to changing conditions and handle different loads effectively. Below are the reasons why flexible couplings are well-suited for such applications:

Misalignment Compensation: Flexible couplings can handle misalignment between shafts, including angular, parallel, and axial misalignment. This capability allows them to accommodate slight shifts in shaft positions that may occur due to thermal expansion, vibration, or other factors, ensuring smooth operation even in changing conditions.

Shock and Vibration Absorption: Flexible couplings can dampen shocks and vibrations that result from sudden changes in load or operating conditions. The flexible element in the coupling acts as a buffer, absorbing and reducing the impact of sudden loads or transient forces, protecting connected equipment and increasing system reliability.

Variable Load Capacity: Flexible couplings come in various designs and materials, each with its load capacity range. Manufacturers provide different coupling models with varying load capacities to accommodate different applications. Properly selecting the right coupling for the specific load conditions ensures reliable power transmission even under varying loads.

Compensation for Thermal Expansion: Temperature changes can cause thermal expansion in mechanical systems, leading to shaft misalignment. Flexible couplings can handle the resulting misalignment, compensating for thermal expansion and ensuring continuous and smooth power transmission.

Torsional Stiffness: Flexible couplings are designed with a balance between flexibility and torsional stiffness. This property allows them to adapt to variable loads while still providing the necessary rigidity for efficient power transmission.

Durable Materials and Designs: Manufacturers produce flexible couplings from durable materials like stainless steel, aluminum, or engineered elastomers. These materials ensure that the couplings can withstand varying operating conditions, including temperature fluctuations, harsh environments, and high loads.

Dynamic Behavior: Flexible couplings have a dynamic behavior that enables them to operate smoothly and efficiently under changing loads and speeds. They can handle variations in rotational speed and torque while maintaining consistent performance.

Application Flexibility: Flexible couplings find applications in a wide range of industries, from automotive and aerospace to industrial and marine. Their versatility allows them to accommodate variable operating conditions and loads in different systems.

Summary: Flexible couplings are well-suited for applications with variable operating conditions and loads. Their ability to compensate for misalignment, absorb shocks and vibrations, and handle thermal expansion make them reliable components in mechanical systems. The availability of various coupling designs and materials allows for the selection of the appropriate coupling based on the specific application requirements, ensuring optimal performance and longevity in variable conditions.

What are the key considerations for selecting a flexible coupling for high-speed applications?

When selecting a flexible coupling for high-speed applications, several critical considerations should be taken into account to ensure optimal performance and reliability:

- Material and Design: Choose a flexible coupling made from high-quality materials that can withstand the high rotational speeds without experiencing excessive wear or fatigue. Consider designs that are specifically engineered for high-speed applications, ensuring they have the required torsional stiffness and damping characteristics.

- Balance: Imbalance at high speeds can lead to vibration and reduce the lifespan of the coupling and connected components. Look for precision-balanced flexible couplings that minimize vibration and avoid any potential resonance issues at operating speeds.

- Torsional Stiffness: In high-speed applications, torsional stiffness is crucial to maintaining accurate rotational timing and preventing torque losses. Choose a flexible coupling with adequate torsional stiffness to minimize angular deflection under load.

- Dynamic Balancing: Dynamic balancing is essential for flexible couplings used in high-speed applications. A dynamically balanced coupling reduces vibrations caused by rotational imbalances, increasing the smoothness and stability of the system.

- Temperature Resistance: High-speed operations can generate significant heat, so select a flexible coupling that can withstand the elevated temperatures without compromising its mechanical properties or causing premature failure.

- Alignment and Runout Tolerance: Accurate alignment of the coupling with the shafts is crucial to prevent additional stress and vibration. Consider couplings with high runout tolerance and ease of alignment to facilitate proper installation.

- Service Life and Maintenance: Evaluate the expected service life of the flexible coupling in high-speed applications. Low-maintenance couplings are desirable to reduce downtime and maintenance costs.

- Application Specifics: Consider the specific requirements of the high-speed application, such as the magnitude of torque, axial movement, and the presence of shock loads. Choose a coupling that can handle these specific demands while maintaining performance at high speeds.

- Compliance with Standards: Ensure that the selected flexible coupling complies with relevant industry standards and specifications, especially those related to high-speed performance and safety.

By carefully considering these key factors, engineers can choose a flexible coupling that meets the demands of high-speed applications, delivering reliable and efficient power transmission while minimizing the risk of premature wear, vibration, and downtime.

What are the advantages of using flexible couplings in mechanical systems?

Flexible couplings offer several advantages in mechanical systems, making them essential components in various applications. Here are the key advantages of using flexible couplings:

- Misalignment Compensation: One of the primary advantages of flexible couplings is their ability to compensate for shaft misalignment. In mechanical systems, misalignment can occur due to various factors such as installation errors, thermal expansion, or shaft deflection. Flexible couplings can accommodate angular, parallel, and axial misalignment, ensuring smooth power transmission and reducing stress on the connected equipment and shafts.

- Vibration Damping: Flexible couplings act as damping elements, absorbing and dissipating vibrations and shocks generated during operation. This feature helps to reduce noise, protect the equipment from excessive wear, and enhance overall system reliability and performance.

- Torsional Flexibility: Flexible couplings provide torsional flexibility, allowing them to handle slight angular and axial deflections. This capability protects the equipment from sudden torque fluctuations, shock loads, and torque spikes, ensuring smoother operation and preventing damage to the machinery.

- Overload Protection: In case of sudden overloads or torque spikes, flexible couplings can absorb and distribute the excess torque, protecting the connected equipment and drivetrain from damage. This overload protection feature prevents unexpected failures and reduces downtime in critical applications.

- Reduce Wear and Maintenance: By compensating for misalignment and damping vibrations, flexible couplings help reduce wear on the connected equipment, bearings, and seals. This results in extended component life and reduced maintenance requirements, leading to cost savings and improved system reliability.

- Compensation for Thermal Expansion: In systems exposed to temperature variations, flexible couplings can compensate for thermal expansion and contraction, maintaining proper alignment and preventing binding or excessive stress on the equipment during temperature changes.

- Electric Isolation: Some types of flexible couplings, such as disc couplings, offer electrical isolation between shafts. This feature is beneficial in applications where galvanic corrosion or electrical interference between connected components needs to be minimized.

- Space and Weight Savings: Flexible couplings often have compact designs and low inertia, which is advantageous in applications with space constraints and where minimizing weight is crucial for performance and efficiency.

- Cost-Effectiveness: Flexible couplings are generally cost-effective solutions for power transmission and motion control, especially when compared to more complex and expensive coupling types. Their relatively simple design and ease of installation contribute to cost savings.

In summary, flexible couplings play a vital role in mechanical systems by providing misalignment compensation, vibration damping, overload protection, and torsional flexibility. These advantages lead to improved system performance, reduced wear and maintenance, and enhanced equipment reliability, making flexible couplings a preferred choice in various industrial, automotive, marine, and aerospace applications.

editor by CX 2024-02-19

China best Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine Tools

Product Description

Product Description

Product Parameters

| product | Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine tools |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2 .Do you accept small order?

If your order bearings are our standard size, we accept even 1pcs.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How does a flexible coupling contribute to the longevity of connected equipment?

A flexible coupling plays a crucial role in enhancing the longevity of connected equipment in various ways. It acts as a mechanical interface between two shafts, connecting them while accommodating misalignment, dampening vibrations, and transmitting torque. Here’s how a flexible coupling contributes to the longevity of connected equipment:

- Misalignment Compensation: One of the primary functions of a flexible coupling is to compensate for both angular and parallel misalignment between two shafts. Misalignment can occur due to various factors, including thermal expansion, assembly errors, or settling of foundation, which can exert excessive stress on the connected equipment. By allowing misalignment, the flexible coupling reduces the stress transmitted to the shafts and connected components, preventing premature wear and failure.

- Shock and Vibration Dampening: Flexible couplings are designed to absorb shocks and dampen vibrations that occur during operation. Vibrations and shocks can be detrimental to connected equipment, leading to fatigue, wear, and premature failure of components. The coupling acts as a buffer, reducing the impact of vibrations and protecting the equipment from potential damage.

- Reduced Stress Concentration: A rigid coupling can create stress concentration points on the shafts, leading to fatigue and cracking over time. Flexible couplings distribute the load more evenly along the shafts, reducing stress concentration and minimizing the risk of failure.

- Transmitting Torque Smoothly: Flexible couplings transmit torque from one shaft to another smoothly, without introducing sudden torque spikes or shocks. This even torque transfer prevents sudden loading on connected equipment, minimizing the risk of damage or accelerated wear on gears, bearings, and other components.

- Controlling Torsional Vibrations: In systems where torsional vibrations are a concern, certain types of flexible couplings are designed to address this issue. These couplings help control torsional vibrations, which can be damaging to the equipment and cause premature failure.

- Thermal Expansion Compensation: When the equipment operates at different temperatures, thermal expansion can lead to misalignment between the shafts. A flexible coupling can accommodate the thermal expansion, ensuring that the connected equipment remains aligned and preventing stress on the components.

- Isolation from External Forces: External forces like impact loads or shaft disturbances can affect the connected equipment. A flexible coupling isolates the equipment from these external forces, protecting it from potential damage.

By providing these essential functions, a flexible coupling helps extend the lifespan of connected equipment by reducing wear and tear, preventing premature failures, and ensuring smooth, reliable operation. The longevity of the connected equipment ultimately results in reduced maintenance costs and increased productivity.

How does a flexible coupling handle torsional vibrations in rotating machinery?

A flexible coupling is designed to handle torsional vibrations in rotating machinery by providing a degree of flexibility and damping. Torsional vibrations are oscillations that occur in the drivetrain due to torque variations, sudden load changes, or other transient events. These vibrations can lead to resonance, excessive stress, and premature failure of components.

Flexible couplings mitigate torsional vibrations through the following mechanisms:

- Torsional Compliance: Flexible couplings have an element, such as an elastomeric insert, that can deform or twist to absorb torsional shocks. When the drivetrain experiences torsional vibrations, the flexible element flexes, effectively isolating and dampening the vibrations before they propagate further.

- Damping: Many flexible couplings have inherent damping properties, especially those with elastomeric components. Damping dissipates the energy of the torsional vibrations, reducing their amplitude and preventing resonance from occurring.

- Tuned Design: Some flexible couplings are specifically designed with specific torsional characteristics to match the drivetrain’s requirements. By tuning the coupling’s stiffness and damping properties, engineers can ensure optimal torsional vibration control.

- Torsional Stiffness: While flexible couplings provide flexibility to absorb vibrations, they also offer a degree of torsional stiffness to maintain the torque transmission efficiency between the shafts.

It is important to select the appropriate flexible coupling based on the specific torsional characteristics and requirements of the rotating machinery. Different applications may demand different types of couplings with varying levels of flexibility and damping. High-performance flexible couplings can effectively minimize torsional vibrations, protecting the drivetrain and connected equipment from excessive stress and potential damage.

Additionally, proper alignment of the flexible coupling during installation is crucial to ensure its optimal performance in mitigating torsional vibrations. Misalignment can introduce additional stresses and exacerbate torsional issues in the system. Regular inspection and maintenance of the flexible coupling will help identify any signs of wear or damage that may affect its ability to handle torsional vibrations effectively.

How does a flexible coupling protect connected equipment from shock loads and vibrations?

Flexible couplings play a crucial role in protecting connected equipment from shock loads and vibrations by providing damping and isolation capabilities. When machines or mechanical systems experience sudden shock loads or vibrations, the flexible coupling acts as a buffer, absorbing and dissipating the impact, thereby reducing the transmitted forces and protecting the equipment. Here’s how flexible couplings achieve this:

- Damping of Vibrations: Flexible couplings are often made from materials that exhibit damping properties. When vibrations are transmitted through the shafts, the flexible coupling’s material can absorb a portion of the vibrational energy, converting it into heat. This dissipation of energy helps reduce the amplitude of the vibrations and prevents them from propagating further into the connected equipment.

- Vibration Isolation: In addition to damping vibrations, flexible couplings also offer a degree of vibration isolation. They are designed to decouple the two shafts, which means that vibrations occurring on one shaft are not directly transmitted to the other shaft. This isolation effect prevents vibrations from propagating across the entire system and minimizes the impact on sensitive equipment or nearby components.

- Shock Absorption: When the connected machinery experiences sudden shock loads, such as during a startup or abrupt changes in load, the flexible coupling can act as a shock absorber. The coupling’s design allows it to deform slightly under the impact, absorbing and distributing the shock energy. This prevents the shock from being directly transferred to the connected equipment, reducing the risk of damage or premature wear.

- Misalignment Compensation: Flexible couplings are capable of compensating for misalignment between the shafts. Misalignment can lead to additional stresses and vibrations in the system. By allowing for some degree of angular, parallel, and axial misalignment, the flexible coupling reduces the forces transmitted to the connected equipment and the supporting structures.

- Reduction of Resonance Effects: Resonance is a phenomenon that occurs when the natural frequency of a system matches the frequency of external vibrations, leading to amplified vibrations. Flexible couplings can help avoid resonance effects by altering the system’s natural frequency and providing some level of flexibility that damps the resonance response.

By incorporating a flexible coupling into the drivetrain or power transmission system, equipment manufacturers and operators can significantly improve the reliability and longevity of connected machinery. The coupling’s ability to dampen vibrations, isolate shocks, and compensate for misalignment contributes to a smoother and more stable operation, reducing maintenance requirements and enhancing overall system performance.

In summary, flexible couplings act as protective elements, shielding connected equipment from shock loads and vibrations. Their ability to dampen vibrations, isolate shocks, and compensate for misalignment contributes to a smoother and more reliable operation of various mechanical systems.

editor by CX 2024-02-13

China factory Metal Star Typecustom Stainless Steel Aluminum Flexible Shaft Jaw Coupling for Packaging Machine

Product Description

Description:

One of the most widely applied types of flexible couplings is an elastomeric design known as the jaw coupling. This design is characterised by 2 hubs, each having 2 or more thick, stubby protrusions around their perimeters, called jaws, pointing toward the opposing hub. These jaws mesh loosely when the 2 hubs are brought together. Filling the gaps between the jaws are blocks of elastomeric material, usually molded into a single asterisk-shaped element called a “spider”.

Just as coupling designs vary to satisfy different application criteria, so do the spiders in jaw-type couplings. The spider is the key determinant of the torque rating of each jaw coupling. It also can make a significant difference in the coupling’s response to vibration, temperature, chemicals, misalignment, high RPM, space limitations and ease of installation or removal.

Paramters:

Features:

1, Elastic plum-shaped flexible coupling

2,During transmission, it can realize zero backlash torque transmission torque under low torque state

3,The elastic spacer is made of polyurethane, and the torque exceeds the traditional claw coupling by more than 2 times

4,Plum CHINAMFG elastomer can resist oil and electrical insulation, operating temperature: -20ºC~80ºC

5,Excellent elastic effect to absorb vibration, eccentricity and deflection

6,If there are multiple deviations, the allowable value of a single deviation will be reduced

Packing & Delivery:

Application:

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Printing Shops, Construction works , Energy & Mining.

About us:

HangZhou CHINAMFG machinery technology Co., Ltd is an industry transmission solutions manufacuturer and service provider.

We offer 1 stop solution for power transmission products for different factories, such as chemicals, energy, material handling, environmental, extraction, pulp and paper, steel and metal, food and beverage, and construction industries.

We supply: Customised gears, Small gearmotors, Industrial gearboxes, Motors, Brand product sourcing.

Our industrial Gear, Gearbox, gearmotor and motor are sold to more than 30 countries. High quality, good price, in time response and sincere service are our value and promises. We aim at making happy cooperation with our customers, bring them reliable and comfortable service.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do you install and align a flexible coupling properly to ensure optimal performance?

Proper installation and alignment of a flexible coupling are essential to ensure its optimal performance and longevity. Incorrect installation can lead to premature wear, increased vibrations, and potential equipment failure. Below are the steps to install and align a flexible coupling properly:

1. Pre-Installation Inspection:

Before installation, inspect the flexible coupling and its components for any visible damage or defects. Check that the coupling’s size and specifications match the application requirements. Ensure that the shafts and equipment connected to the coupling are clean and free from debris.

2. Shaft Preparation:

Prepare the shafts by removing any oil, grease, or contaminants from the surfaces that will come into contact with the coupling. Ensure that the shaft ends are smooth and free from burrs that could affect the fit of the coupling.

3. Coupling Hub Installation:

Slide the coupling hubs onto the shafts, ensuring they are positioned securely and evenly on each shaft. Use a lubricant recommended by the manufacturer to facilitate the installation and ensure a proper fit.

4. Alignment:

Proper alignment is critical for the performance and longevity of the flexible coupling. Align the shafts by checking both angular and parallel misalignment. Utilize precision alignment tools, such as dial indicators or laser alignment systems, to achieve accurate alignment. Follow the manufacturer’s alignment specifications and tolerance limits.

5. Tightening Fasteners:

Once the shafts are properly aligned, tighten the coupling’s fasteners to the manufacturer’s recommended torque values. Gradually tighten the fasteners in a cross pattern to ensure even distribution of the load on the coupling hubs. Avoid over-tightening, as it may cause distortion or damage to the coupling.

6. Run-Out Check:

After installation, perform a run-out check to verify that the coupling’s rotating components are balanced and aligned. Excessive run-out can lead to vibrations and reduce the coupling’s performance. If significant run-out is detected, recheck the alignment and address any issues that may be causing it.

7. Lubrication:

Ensure that the flexible coupling is adequately lubricated, following the manufacturer’s recommendations. Proper lubrication reduces friction and wear, enhancing the coupling’s efficiency and reliability.

8. Periodic Inspection and Maintenance:

Regularly inspect the flexible coupling for signs of wear, misalignment, or damage. Address any issues promptly to prevent further problems. Depending on the coupling type and application, scheduled maintenance may include re-greasing, re-alignment, or replacing worn components.

Summary:

Proper installation and alignment are crucial for ensuring the optimal performance and longevity of a flexible coupling. Following the manufacturer’s guidelines, inspecting the components, achieving accurate alignment, and using the appropriate lubrication are key steps in the installation process. Regular inspection and maintenance help to identify and address potential issues, ensuring the coupling continues to operate smoothly and efficiently in the mechanical system.

How does a flexible coupling handle misalignment in large rotating equipment?

Flexible couplings are designed to accommodate various types of misalignment in large rotating equipment, ensuring smooth and efficient power transmission while minimizing stress on connected components. Here’s how flexible couplings handle different types of misalignment:

- Angular Misalignment: Angular misalignment occurs when the axes of the two connected shafts are not collinear and form an angle. Flexible couplings can handle angular misalignment by allowing the coupling elements to flex and move slightly, thus accommodating the angle between the shafts. The flexible elements, often made of elastomeric materials or metallic membranes, can bend and twist to compensate for angular misalignment, ensuring that the coupling remains engaged and transfers torque effectively.

- Parallel Misalignment: Parallel misalignment, also known as offset misalignment, happens when the two shafts are not perfectly aligned along their axes, resulting in a lateral shift. Flexible couplings can handle parallel misalignment through their ability to move radially, allowing the flexible elements to adjust and take up the offset. This capability prevents excessive side loads on the shafts and bearings, reducing wear and increasing the lifespan of the equipment.

- Axial Misalignment: Axial misalignment occurs when there is a linear displacement of one shaft relative to the other, either toward or away from the other shaft. Some flexible couplings, such as certain types of flexible disc couplings, can accommodate a limited amount of axial misalignment. However, for large axial movement, other types of couplings or special designs may be required.

The flexibility of the coupling elements allows them to act as a buffer between the shafts, dampening shocks, vibrations, and torsional forces caused by misalignment or other dynamic loads. This helps protect the connected equipment from damage and enhances the overall performance and reliability of the rotating system.

In large rotating equipment, where misalignment is more common due to thermal expansion, foundation settling, or other factors, flexible couplings play a critical role in maintaining smooth operation and reducing stress on the machinery. However, it is essential to choose the appropriate type of flexible coupling based on the specific requirements of the application and to regularly inspect and maintain the coupling to ensure optimal performance and longevity.

What role does a flexible coupling play in reducing downtime and maintenance costs?

A flexible coupling plays a significant role in reducing downtime and maintenance costs in industrial machinery and rotating equipment. Here are the key ways in which flexible couplings contribute to these benefits:

- Misalignment Compensation: One of the primary functions of a flexible coupling is to accommodate misalignment between two connected shafts. Misalignment can occur due to various factors such as thermal expansion, foundation settling, or manufacturing tolerances. By allowing for misalignment, flexible couplings reduce the transmission of harmful forces and stresses to connected components, minimizing wear and preventing premature failures that could lead to costly downtime and repairs.

- Vibration Damping: Flexible couplings have inherent damping properties due to the elastomeric or flexible elements they incorporate. These elements absorb and dissipate vibration and shock loads that may arise from the operation of rotating machinery. By dampening vibrations, flexible couplings protect the connected equipment from excessive wear and fatigue, extending their service life and reducing the need for frequent maintenance or replacement.

- Shock Load Absorption: In applications where sudden loads or shocks are common, such as in heavy machinery or high-speed equipment, flexible couplings act as shock absorbers. They can absorb and dissipate the impact energy, preventing damage to the machinery and minimizing downtime caused by unexpected failures or breakdowns.

- Easy Installation and Alignment: Flexible couplings are designed for ease of installation and alignment. Unlike rigid couplings that require precise shaft alignment, flexible couplings can tolerate some degree of misalignment during installation. This feature simplifies the setup process, reduces installation time, and lowers the risk of misalignment-related issues, ultimately minimizing downtime during initial installation or replacement of couplings.

- Reduced Maintenance Frequency: The ability of flexible couplings to handle misalignment and dampen vibrations results in reduced wear on bearings, seals, and other connected components. Consequently, the frequency of maintenance intervals can be extended, reducing the need for frequent inspections and component replacements. This directly translates to lower maintenance costs and less downtime for maintenance tasks.

- Equipment Protection: By reducing the transmission of shock loads and vibrations, flexible couplings act as protective barriers for connected equipment. They help prevent catastrophic failures and subsequent damage to expensive machinery, avoiding unplanned shutdowns and costly repairs.

Overall, flexible couplings are critical components that improve the reliability and longevity of rotating equipment. Their ability to handle misalignment, dampen vibrations, and protect against shock loads contributes to reduced downtime, lower maintenance costs, and increased productivity in industrial applications.

editor by CX 2024-02-09

China manufacturer & factory supplier for China in Gothenburg Sweden manufacturer CNC machine HTD 3M PU open ended timing belt With high quality best price & service

ISO 9001:2000 qualified. Stocking distributor of power transmission goods like roller & multiple strand roller chains. Goods also incorporate brakes, push components, gears, torque limiters, U-joints, pulleys, sheaves, encoders, belt drives, clutches & motors are also offered.The higher specific CNC equipment, these kinds of as Slow-feeding wire-minimize equipment, jig grinding machine and electric discharge device, guarantees the top quality precision of mould processing, with the higher efficient and environmental safety acid rolling line becoming the greatest uncooked content converting products in the area in china The wildly use of automatic milling equipment, higher-speed automated feeding punch, high speed automatic rolling and assembling equipment ensures the higher top quality and performance of factors and chain producing.

Overview

Swift Information

- Relevant Industries:

-

Creating Materials Retailers, Production Plant, Equipment Mend Shops, Food & Beverage Manufacturing facility, Farms, Vitality & Mining

- Solution identify:

-

Timing belt

- Shade:

-

Black

- Software:

-

Electrical power Transmission Belt

- Dimension:

-

Normal Dimension

- Function:

-

Minimal Noisy

- Good quality:

-

Beneath the assistance of managerial perception of “Serving agriculture, scoring a good results by way of high quality of products and honesty in enterprise”, our items have been dependable by consumers and have acquired a greater share of marketplace.

Large Level

- Packing:

-

Cartons

- Pitch:

-

3mm

- Benefit:

-

Higher efficiency

- Tooth:

-

37-880

Supply Ability

- Source Capacity:

- 50000 Meter/Meters for every Month

Packaging & Supply

- Packaging Details

- Carton box+ wood situation

- Port

- Tianjin/Shanghai/Ningbo

-

Direct Time

: -

Quantity(Baggage) Rewards of Worm Gears

1 – 200 201 – 1000 >1000 Est. Time(days) 15 twenty To be negotiated

Online Customization

EPG offer you widest range of gearbox and velocity reducers, conveyor chains and transmission areas like equipment, sprocket, racks, pulley, shaves and taper bushes etc for various applications

Item Description

|

Item identify |

Timing belt |

||||||

|

Substance |

Rubber,PU, steel wire |

||||||

|

Variety |

Open up,round |

||||||

|

Product dimension |

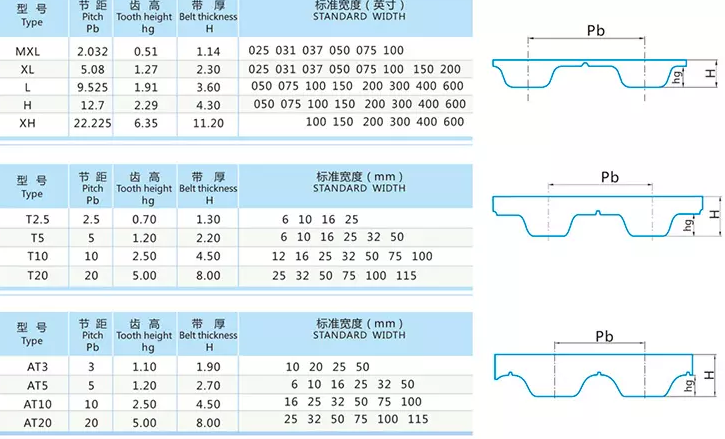

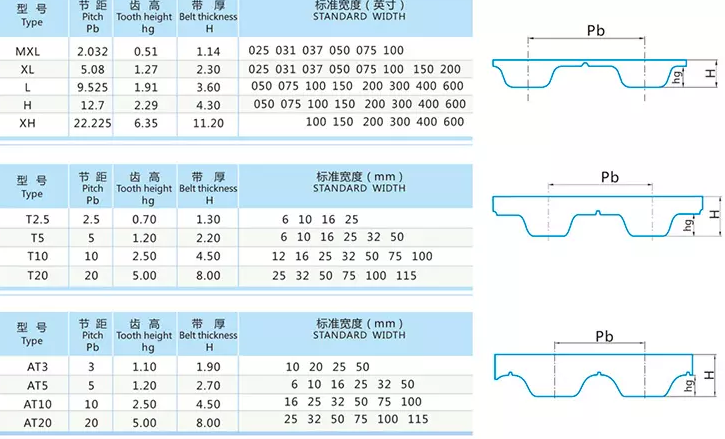

T variety:MXL,XL,L,H,XH,T2.5,T5,T10,T20,AT5,AT10,AT20 |

||||||

|

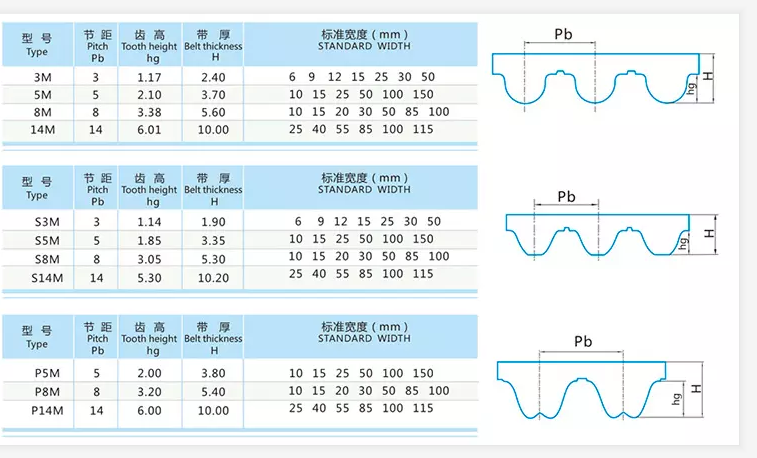

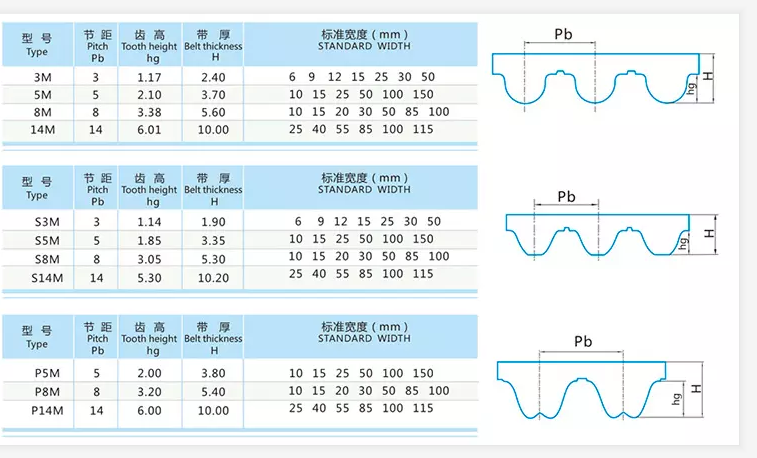

Arc kind:2M,3M,5M,8M,14M,20M,S2M,S3M,forty four.5M,S5M,S8MS14M |

|||||||

|

Color |

Black,white,inexperienced,ect |

||||||

|

authentic area |

China |

||||||

|

Gain |

Large toughness, anti oil, warmth, growing older,Great bending resistant functionality |

||||||

|

Feature |

one. Polyurethane Open Ended Timing belt—-infinite extended or joined limitless kind. |

||||||

|

Application |

belt extensively employed in device resources, textile, printing, meals packaging, wire and cable, devices and meters, petroleum chemical, |

||||||

Various kind timing belt

ARC variety

T kind

Open up type

Spherical kind

Software

Catalog

Payment

Our Business

HangZhou EPG – The most significant transmission parts manufacuturer in China Electrical Products Co.,Ltd was started in HangZhou in 2008 and is a expert maker and exporter that is involved with the layout, advancement and creation.With in depth requirments, we can also create your specific created merchandise. Our item range contains all types of helical equipment, spur equipment, bevel gear, gear rack, worm gear, sprockets,chains, bearings.Keeping in mind that excellent provider is the important to cooperating with customers, we try to fulfill large high quality expectations, supply aggressive charges and make certain prompt delivery. In this way, our goods have ongoing to achieve marketplace acceptance and clients pleasure in excess of the earlier couple of many years. We are aiming to meet up with the needs of the consumers all around the planet..If you are interested in any of our products or would like to examine a possible order, you should truly feel free to contact us. We are seeking ahead to developing profitable enterprise relationships with new clientele all around the planet in the foreseeable future.

· Our Basic principle: “Reliability Supremacy, and Client Very first”

· Our Guarantee: “Higher quality productsThe EP Line PTO travel shafts are recognizable since of the EP Line patented coupling system and the flexible cone. The PTO push shafts are distinguished by way of user-friendliness, compactness and appealing design and style., and Excellent Provider”